UV Light Curing System – A Efficient Solution for Industrial Manufacturing

In today’s industrial manufacturing environment, where high speed, absolute precision, and optimized operating costs are essential, the UV Light Curing System has become an indispensable technological solution. This article provides a comprehensive overview of the structure, practical applications, and selection criteria of UV Light Curing Systems for modern production models.

1. Introduction to UV Curing Machines – The Foundation of Modern Curing Technology

As industrial production increasingly demands speed, precision, and long-term stability, traditional thermal drying methods are revealing clear limitations, such as long curing times, high energy consumption, and difficulty integrating into automated production lines. This is why the UV Light Curing System is being widely adopted as a core industrial technology.

UV curing machines operate based on the principle of using ultraviolet radiation to trigger photochemical reactions in UV inks, UV adhesives, or UV coatings. This process enables materials to cure almost instantly, without prolonged heating and without dependence on ambient environmental conditions.

2. Structure of the UV Light Curing System

To ensure stable operation and optimal curing performance, a standard UV Light Curing System typically consists of the following key components:

2.1. UV LED Light Source

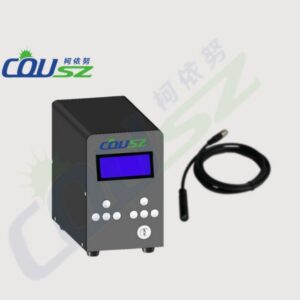

The UV source is the “heart” of the system, directly determining curing performance. UV LED light sources commonly operate at wavelengths such as 365nm, 385nm, 395nm, and 405nm. UV LED technology is increasingly dominant due to its long lifespan, high stability, and energy efficiency.

LIGHT SOURCE

| Item | Specification | Item | Specification |

|---|---|---|---|

| Light emitting area (mm) | Custom design | Applications | Ink curing (especially inkjet), adhesive curing (CCM, VCM), inspection, etc. |

| Cooling | Air cooling (fan) | LED lifetime | >20,000 hours |

| Weight / Material | Approx. 3 kg / Metal, aluminum | Wavelength (nm) | 365 / 385 / 395 / 405 |

| Intensity (mW/cm²) | Customizable | Monitoring | Intensity, temperature, etc. |

| Connection cable | 2–5 m (customizable) |

2.2. Cooling System

During operation, the UV source generates heat. Therefore, the UV Light Curing System is equipped with either air-cooling or water-cooling systems to ensure safe operating temperatures and stable UV output.

2.3. Controller Unit

The controller allows users to configure key operating parameters, including:

-

UV output power

-

Exposure time

-

Continuous or intermittent operation modes

In advanced systems, the controller can also integrate with PLC, HMI, or IoT platforms for remote monitoring and control.

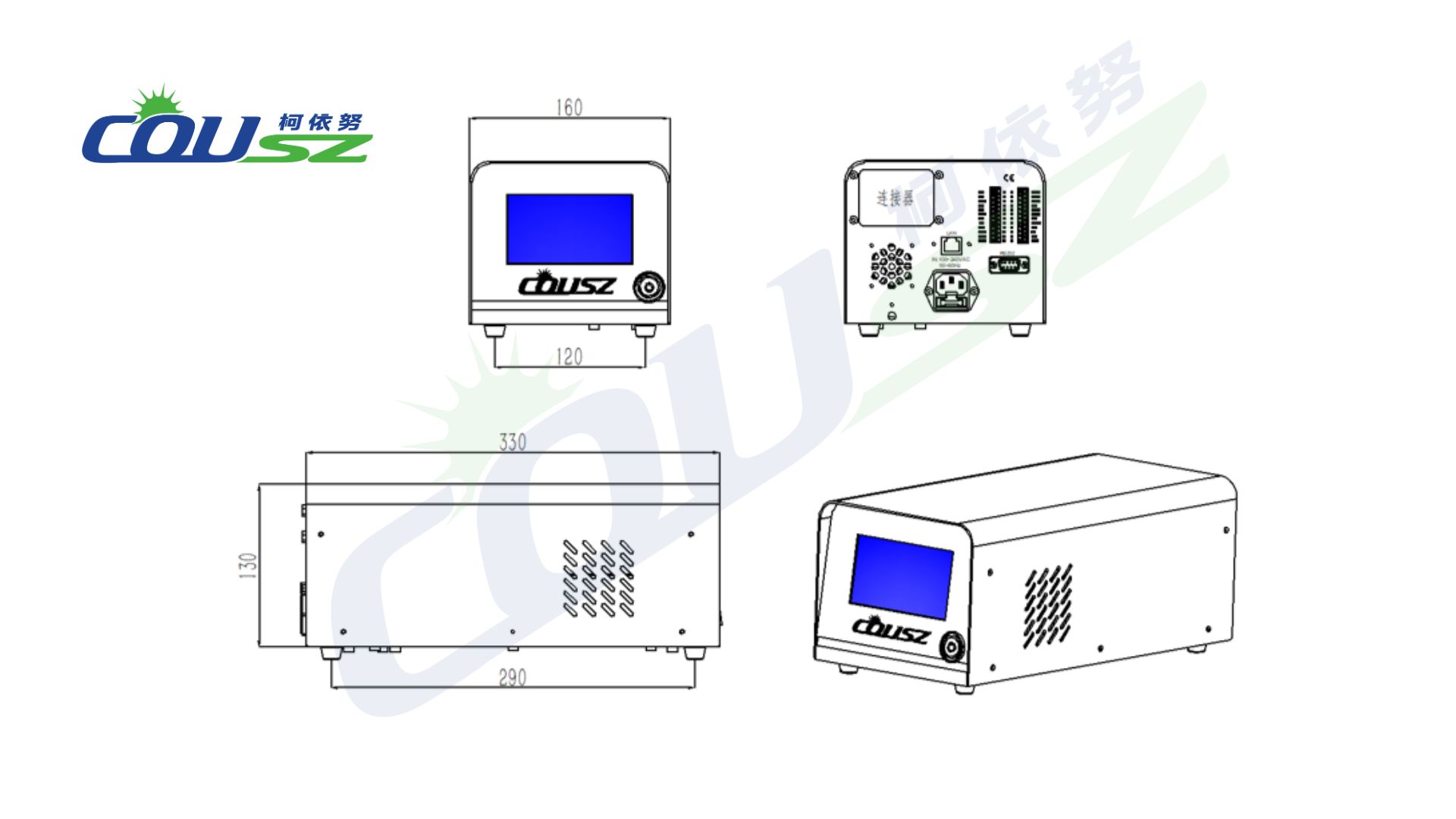

| Item | Specification | Item | Specification |

|---|---|---|---|

| Dimensions (mm) | L330 × W160 × H130 | Power | 50W |

| Cooling | Fan cooling | Input power | 100–240V AC, 50–60Hz |

| Weight / Material | Approx. 3.5 kg / Metal | Output power | 10%–100% |

| Parameter lock | Password-protected advanced settings | Display & setting | Touch screen; time, intensity |

| LED light heads | 1–4 units | Control | Foot pedal, SCM, PLC, RS232 / RS485 / TCP |

| Alarm | Over-temperature and system fault alarms | Operating time | Cumulative usage record |

3. Applications of the UV Light Curing System in Industry

Thanks to its fast curing speed and precise control, the UV Light Curing System is widely used across various industries:

3.1. Printing Industry

UV curing machines are used to cure UV inks in inkjet printing, screen printing, and high-end packaging printing. After curing, surfaces exhibit excellent adhesion, sharp colors, and no smearing.

3.2. Electronics & Camera Module Industry

In the production of camera modules, sensors, and electronic components, the UV Light Curing System plays a critical role in curing UV adhesives (CCM, VCM), ensuring micron-level precision and long-term stability.

3.3. Industrial Coating & Surface Finishing

UV coatings applied in wood processing, metal finishing, and engineering plastics are rapidly cured, increasing surface hardness, scratch resistance, and overall product value.

3.4. Medical & Optical Industries

In medical and optical applications, UV curing machines support the manufacturing of devices requiring high cleanliness standards, precision, and process repeatability.

4. Comparison Between Air-Cooled and Water-Cooled UV Light Curing Systems

The cooling system significantly affects durability and performance. Below is a detailed comparison of the two common cooling methods:

4.1. Fan Cooling

Advantages:

-

Simple structure

-

Lower initial investment cost

-

Easy maintenance

Limitations:

-

Limited cooling efficiency

-

Higher operational noise

-

Not suitable for high UV power or high-temperature environments

Air-cooled systems are generally suitable for small to medium-power UV curing applications.

4.2. Water-Cooled

Advantages:

-

Superior cooling performance

-

Stable operation at high UV output

-

Longer UV source lifespan

Limitations:

-

Higher initial investment cost

-

Requires a dedicated cooling system

For continuous production lines and high-intensity UV applications, water-cooled UV Light Curing Systems are the optimal choice for long-term operational stability.

Contact for UV Light Curing System Consultation

Are you looking for a UV Light Curing System that perfectly matches your production line?

Contact COUSZ today for in-depth technical consultation:

Contact person: Ms. Yuna

Hotline: +84 965 535 348

Email: sales03@cousz.com

UV Light Curing System

UV Light Curing System enables fast, precise, and energy-efficient curing for industrial printing, electronics, coating, and UV adhesive applications.

Product SKU: COUSZCVX00E

Product Brand: COUSZ

Product Currency: VND

Product Price: 6668

Price Valid Until: 2025-12-31

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Perfect for my needs.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com