UV Light Conveyor – Uniform Adhesive Curing Solution for Modern Manufacturing

In modern industrial manufacturing, production lines are required to operate at high speed, maintain consistent quality, and handle large product volumes efficiently. Traditional UV curing methods are increasingly showing limitations, especially for products that require adhesive curing on both side surfaces. Manual curing or single-direction UV exposure can no longer meet today’s productivity and quality standards. The UV Light Conveyor was developed to solve this challenge, providing continuous, uniform, and highly efficient dual-side UV curing for industrial applications.

1. Overview of the UV Light Conveyor

The UV Light Conveyor is an integrated UV curing system combined with a conveyor belt, where UV light sources are installed on both sides of the conveyor. As products move through the irradiation zone, UV light is applied simultaneously to both side surfaces, allowing UV adhesives to cure quickly and evenly without the need for flipping, rotating, or manual handling.

This solution is particularly suitable for manufacturers operating continuous production lines, where high stability, reduced labor dependency, and consistent product quality across batches are critical requirements.

2. Why Dual-Side UV Curing Is Necessary

In many real-world applications, UV adhesives are not only applied to the top or bottom surfaces but also to edges, joints, or side faces of products. When using conventional single-direction UV curing machines, adhesives in these areas often fail to cure completely, leading to issues such as:

-

Insufficient adhesive hardness

-

Peeling or delamination after short-term use

-

Reduced mechanical strength and sealing performance

-

Increased defect rates, rework, or product rejection

The UV Light Conveyor eliminates these problems by delivering direct and simultaneous UV exposure to both sides of the product, ensuring a complete, consistent, and reliable curing process.

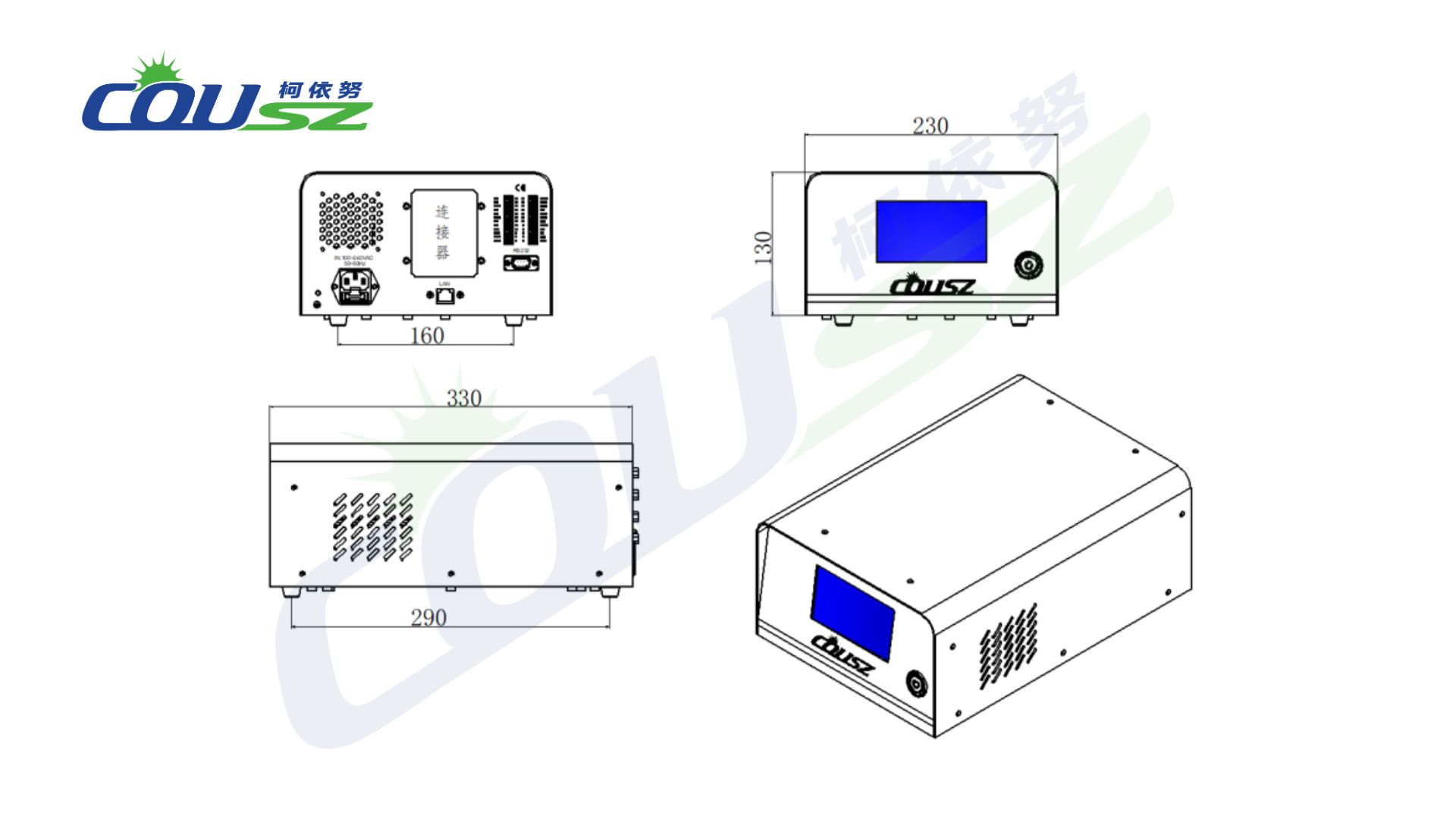

3. Structural Design of the UV Light Conveyor

The system is engineered for industrial environments, with a durable and well-structured design that supports long-term operation:

-

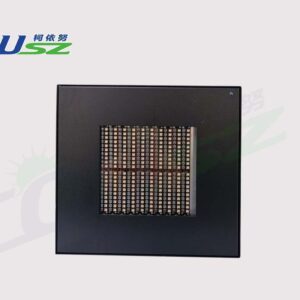

Two UV spot curing units with a beam size of 100 × 100 mm, mounted on both sides of the conveyor

-

A central conveyor belt that transports products smoothly through the UV curing zone

-

Fan-based cooling system for effective heat dissipation from the UV light sources

-

Rigid machine frame that minimizes vibration during continuous operation

-

Control unit that allows adjustment of conveyor speed to match different UV adhesive curing requirements

Thanks to this optimized structure, the UV Conveyor maintains stable performance over extended operating periods without compromising curing quality.

4. Fan Cooling Mechanism – Simple Yet Efficient

One of the notable advantages of this system is its fan-based cooling mechanism. Instead of complex water-cooling systems, industrial fans are used to:

-

Dissipate heat generated by the UV light sources

-

Maintain a stable curing temperature zone

-

Protect electronic components and UV lamps

-

Reduce maintenance complexity and operating costs

This cooling approach is especially suitable for production lines that run continuously, ensuring equipment safety, reliability, and long service life.

Consulting UV Light Conveyor Solutions with COUSZ

Selecting the right UV Light Conveyor depends on several factors, including the type of UV adhesive, product dimensions, and desired production speed.

👉 For professional consultation and a tailored solution for your factory, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

UV Light Conveyor

UV Light Conveyor delivers uniform dual-side UV curing for industrial production lines, ensuring speed, stability, and consistent quality.

Product SKU: COUSZCVC001E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Great design and quality.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com