UV Light Chamber – A High-Efficiency UV Curing Solution for Large-Scale Manufacturing

The UV Light Chamber has become an essential piece of equipment in modern manufacturing lines where large volumes of products must be processed in a short time while maintaining consistent and reliable adhesive curing quality. Unlike small standalone UV curing units, industrial-grade systems are engineered for continuous operation, high automation levels, and superior curing performance.

1. Introduction to the UV Light Chamber

A UV Light Chamber is a high-power UV curing system that typically uses flood or area UV light sources combined with an enclosed curing chamber or an automated conveyor system. This design allows UV adhesives to cure rapidly during continuous production, significantly reducing processing time and increasing overall output.

Compared with manual or semi-automatic curing methods, the UV Chamber is built to support 24/7 factory operation. It is widely applied in industries such as electronics manufacturing, component assembly, industrial printing, and supporting industrial processes where productivity and consistency are critical.

2. Functions of the UV Light Chamber

In real production environments, the UV Chamber plays several key roles:

-

Rapid and uniform curing of UV adhesives over large surface areas

-

High-throughput processing of large product volumes

-

Consistent curing quality across production batches

-

Reduced dependence on manual handling

-

Increased line speed and optimized labor costs

This system is particularly suitable for manufacturers that require continuous, large-scale UV adhesive curing rather than processing individual products one by one.

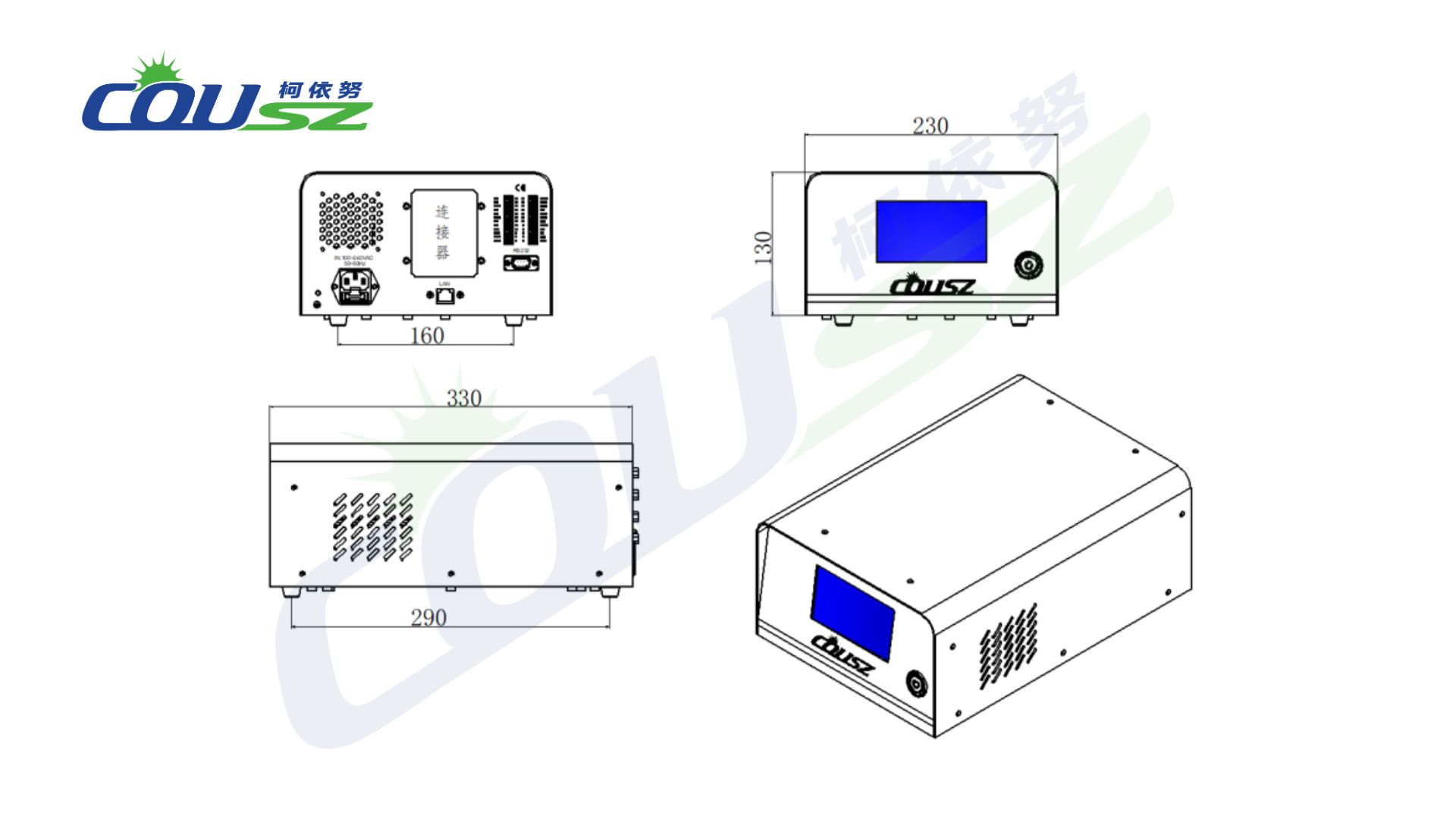

3. Common Structures and Curing Configurations

Most UV Chamber systems are designed in one of the following two main configurations:

Flood UV Curing with Enclosed Chamber

-

Fully enclosed curing chamber to minimize UV leakage

-

Ideal for products requiring controlled curing environments

-

Enhanced operational safety and process stability

Flood UV Curing with Integrated Conveyor

-

Fully automated curing process

-

Products move continuously through the UV irradiation zone

-

Easy integration into existing production lines

Both configurations share the same objective: delivering high curing efficiency with long-term stability and uniform results.

4. High Performance with Higher Initial Investment

Compared with desktop UV units, spot UV systems, or line UV curing machines, the UV Chamber requires a higher initial investment. However, this cost is justified by the value it delivers:

-

High curing power capable of processing multiple products simultaneously

-

Durable operation in demanding industrial environments

-

Reduced downtime and product defects

-

Lower operating cost per unit in long-term production

For medium- to large-scale manufacturers, investing in a UV Curing Chamber is a strategic decision that enhances long-term competitiveness and production efficiency.

UV Light Chamber Solution Consulting with COUSZ

Selecting the right UV Light Chamber depends on multiple factors, including adhesive type, production volume, installation space, and desired automation level.

👉 For professional consultation and the most suitable UV curing solution for your production line, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

UV Light Chamber

UV Light Chamber delivers high-efficiency UV adhesive curing for large-scale, continuous industrial production lines.

Product Brand: COUSZCVI01E

Product Currency: VND

Product Price: 8889

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

No complaints at all.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com