UV Ink Curing Machine – An Optimal Solution for Modern Industrial Printing

In industrial printing, ink curing speed, adhesion strength, and color stability are critical factors that determine product quality. The UV Ink Curing Machine has emerged as an advanced technological solution, enabling UV ink to cure almost instantly, improving productivity, and ensuring consistent results throughout the production process.

With precise control over wavelength and light intensity, this equipment is widely applied in packaging printing, label printing, electronic printing, specialty materials, and automated production lines.

1. What Is a UV Ink Curing Machine?

A UV Ink Curing Machine is a system that emits ultraviolet light to cure UV ink through a photochemical reaction. When UV ink is exposed to UV light at the appropriate wavelength, ink molecules rapidly polymerize, forming a fully cured layer that adheres firmly to the substrate.

Compared with traditional thermal curing methods, the UV Curing Machine offers significant advantages:

-

Extremely fast curing time

-

No material deformation

-

Stable and sharp ink colors

-

Ideal for high-speed printing lines

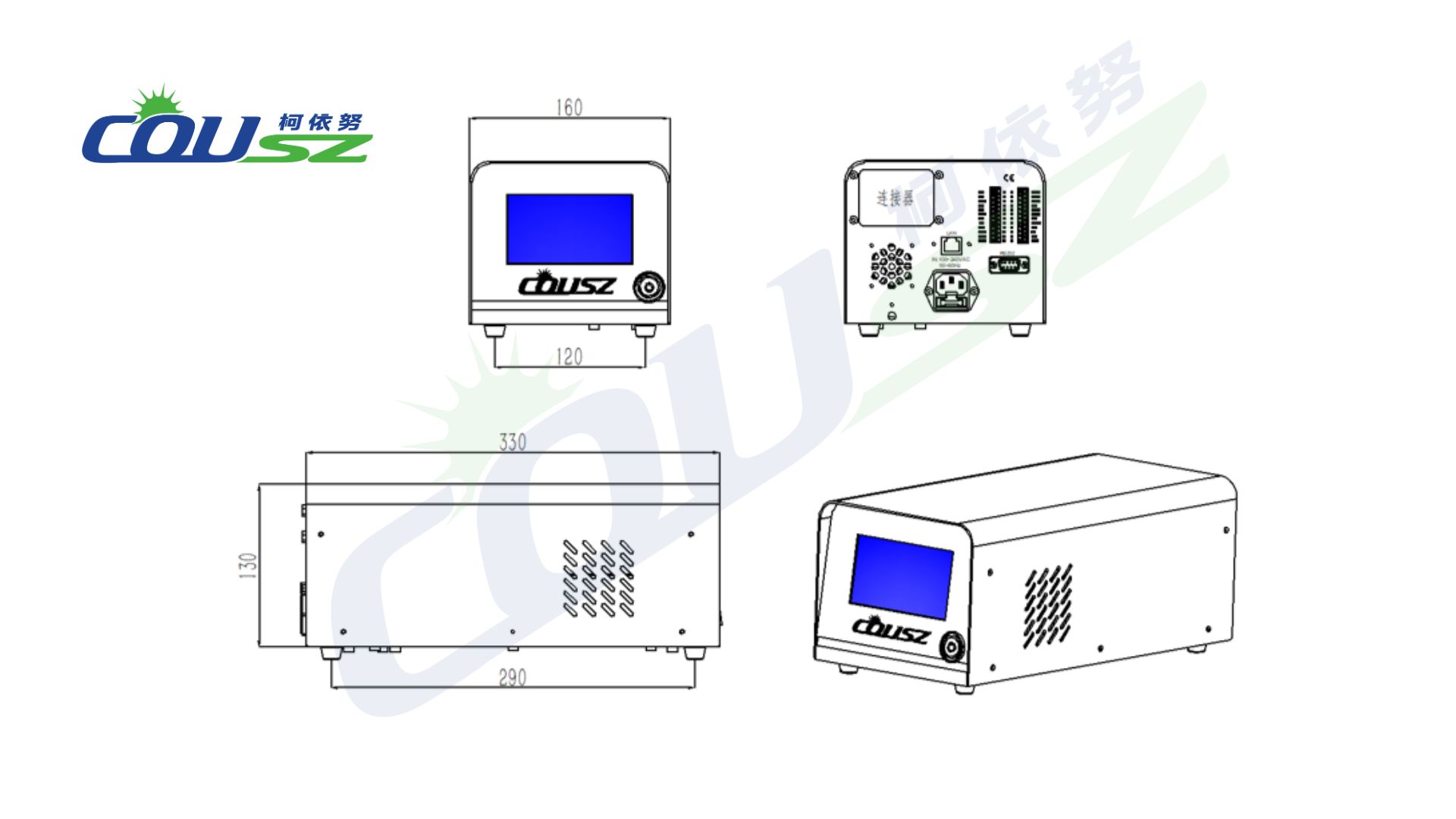

2. Basic Structure of a UV Ink Curing Machine

A standard UV curing system typically consists of the following main components:

2.1. UV Light Source

-

Primarily uses UV LED technology

-

The most common wavelength for ink curing is 395 nm

-

Concentrated and stable UV output, optimized for UV ink properties

2.2. Control System

-

Adjustable light output power

-

Configurable curing time and operating modes

-

Easy integration into automated printing lines

2.3. Cooling System

-

Air cooling or combined cooling solutions

-

Ensures stable operating temperature and extends light source lifespan

3. Comparison Between UV Ink Curing Machines and UV Adhesive Curing Machines

Although both systems use UV light, UV Curing Machines and UV adhesive curing machines differ in several key aspects:

3.1. Wavelength Differences

UV LED Ink Curing Machine:

-

Typically operates at 395 nm

-

Optimized for the photochemical characteristics of UV inks

UV Adhesive Curing Machine:

-

Uses multiple wavelengths (365 nm, 385 nm, 395 nm, etc.)

-

Depends on adhesive type and curing requirements

3.2. Light Output Power Differences

UV Ink Curing:

-

Power optimized for thin ink layers

-

Focus on uniformity and stability

UV Adhesive Curing:

-

Flexible power levels based on adhesive thickness

-

May require higher intensity for certain applications

👉 Choosing the right curing machine is essential to ensure product quality and optimize operating costs.

4. Key Features of the UV Ink Curing Machine

Modern UV Curing Machines are equipped with a range of advanced features, including:

-

Flexible adjustment of UV light output

-

Stable and consistent UV irradiation

-

Multiple cooling options

-

Easy integration with printing and automation systems

-

Energy-efficient operation with long LED lifespan

-

Safe design that minimizes UV radiation leakage

These features help manufacturers improve printing efficiency and achieve better quality control.

UV Ink Curing Solution Consulting with COUSZ

Selecting the right UV Ink Curing Machine depends on ink type, production line speed, and final product quality requirements. COUSZ provides optimized UV solutions tailored to real-world industrial applications.

👉 Contact us for professional consultation:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

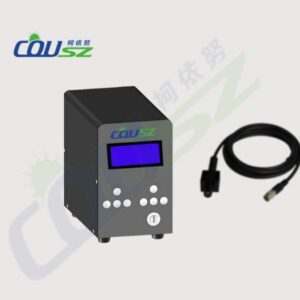

UV Ink Curing Machine

UV Ink Curing Machine delivers instant ink curing, stable colors, and high efficiency for modern industrial printing applications.

Product SKU: COUSZCVC01E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-31

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Excellent overall experience.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com