UV Curing Chamber Optimized for Large-Scale Manufacturing

In modern manufacturing, speed, stability, and scalability are key factors that define a company’s competitive edge. The UV Curing Chamber has emerged as an efficient solution for UV adhesive curing and surface coating, meeting the demand for high-volume processing with consistent quality and continuous operation.

1. What Is a UV Curing Chamber?

A UV Cure Chamber is an integrated system that uses ultraviolet (UV) radiation to dry and cure UV adhesives, UV inks, or surface coatings in large-scale production environments. Unlike standalone UV curing units, this system is typically built directly into production lines and combined with conveyors, enclosed curing chambers, or automated modules.

Thanks to its ability to process multiple products simultaneously, the UV Cure Chamber is especially suitable for electronics manufacturing, industrial printing, precision mechanical components, and advanced material production.

2. Working Principle of a UV Curing Chamber

The core principle of a UV Chamber is based on photochemical reactions. When UV-coated materials pass through the irradiation zone, UV energy activates photoinitiators, triggering polymerization and allowing the material to cure almost instantly.

A typical operating process includes:

-

Products are fed into the curing zone via conveyor belts or robotic handling

-

High-intensity UV light sources (LED or mercury-based) provide uniform irradiation

-

UV adhesives or coatings cure completely within a very short time

-

Finished products achieve high stability and move to the next production stage

With its enclosed design and precise parameter control, the UV Curing Chamber ensures uniform curing quality across all production batches.

3. Practical Applications of the UV Curing Chamber

The UV Cabinet is widely used across various industrial sectors, including:

-

UV adhesive curing for PCB boards and electronic components

-

UV bonding in camera modules and sensor assembly

-

UV ink curing in industrial and packaging printing

-

Surface treatment of plastic, metal, and glass materials

-

Production lines requiring high speed and repeatable quality

For manufacturers handling large daily production volumes, the UV Chamber provides a clear advantage in productivity and quality control.

4. UV Curing Chamber vs. Mercury UV Lamp

| Criteria | UV Chamber | Mercury UV Lamp |

|---|---|---|

| Application scale | Large production lines, mass manufacturing | Small to medium scale |

| Automation level | High, integrated with conveyors | Mostly standalone operation |

| Curing consistency | Uniform across production batches | Highly operator-dependent |

| Long-term efficiency | High, optimized cost per unit | Performance degrades over time |

| Scalability | Flexible and customizable | Limited |

This comparison clearly shows that the UV Cure Chamber is more suitable for manufacturers targeting large-scale, automated production.

5. Benefits of Investing in a UV Curing Chamber

Investing in a UV Curing Oven is not just about purchasing equipment—it is a comprehensive upgrade to manufacturing capability:

-

Shortened curing time and production cycles

-

Reduced defect rates and product rework

-

Improved consistency and quality stability

-

Optimized labor utilization and long-term operating costs

-

Easy integration with modern manufacturing management systems

Although the initial investment is higher than conventional solutions, the long-term value delivered by a UV Cure Chamber is sustainable and cost-effective.

UV Curing Chamber Solution Consulting

Choosing the right UV Chamber depends on multiple factors such as UV adhesive type, required throughput, available installation space, and automation level.

👉 For professional consultation and the most suitable UV Chamber solution for your factory, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

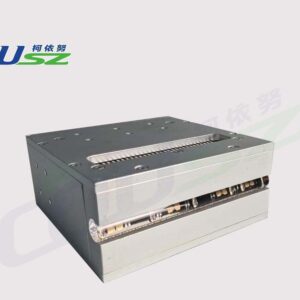

UV Curing Chamber

High-efficiency UV Curing Chamber for large-scale production lines, delivering stable curing, automation, and consistent quality.

Product SKU: COUSZCVI02E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8889

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com