UV Cure Conveyor – An Optimized UV Curing Solution for Modern Production Lines

In modern manufacturing lines, where speed, operational stability, and the ability to process large product volumes are critical factors, the UV Cure Conveyor is increasingly becoming a standard solution. Beyond accelerating the curing of UV adhesives, UV inks, and UV coatings, this system delivers high automation, consistent curing quality, and long-term operational efficiency for manufacturers.

1. What Is a UV Cure Conveyor?

A UV Curing Conveyor is a UV curing system integrated with a conveyor belt, allowing products to move continuously through the UV irradiation zone to complete the curing process. Unlike standalone or intermittent UV curing machines, conveyor-based systems are designed for continuous operation, synchronized with the rhythm of industrial production lines.

Thanks to its “curing-on-the-move” mechanism, the system eliminates waiting time, reduces manual handling, and ensures that each product receives stable and consistent UV energy exposure.

2. Basic Structure of a UV Cure Conveyor

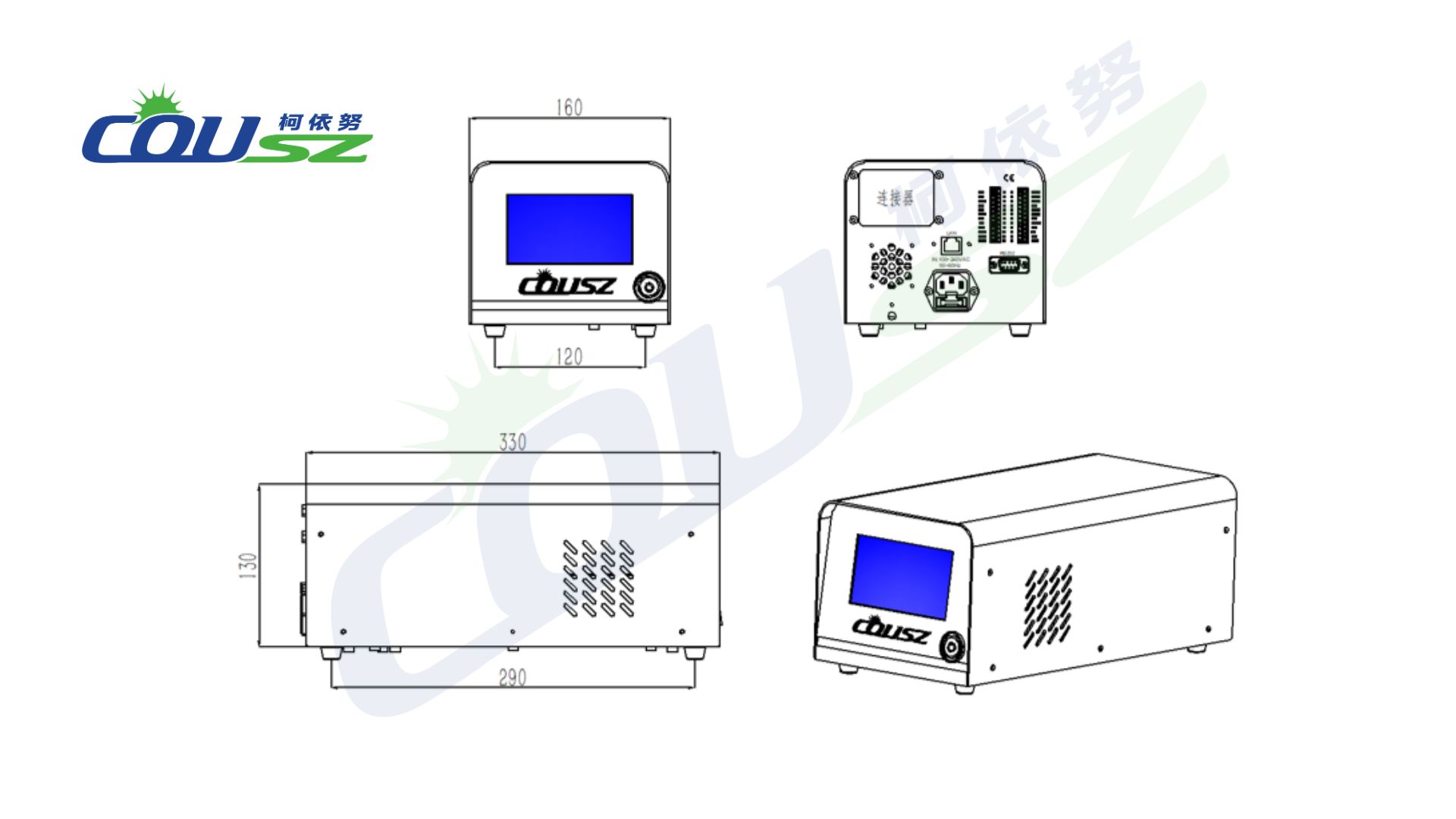

Overall, the structure of the UV Curing Conveyor is compact yet optimized for industrial environments:

-

A central conveyor belt that transports products smoothly through the curing zone

-

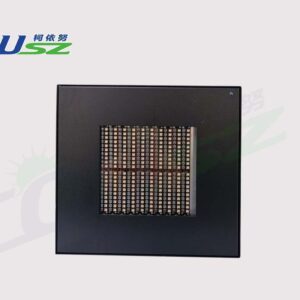

UV light sources (LED or mercury lamps) positioned above or from multiple directions

-

An enclosed curing chamber to improve efficiency and enhance operational safety

-

A fan-based cooling system that supports stable long-term operation

-

A control unit that allows adjustment of conveyor speed and curing time

This configuration allows the system to be easily integrated into existing production lines without requiring major changes to factory layout.

3. UV Cure Conveyor vs. UV Curing Oven

Many manufacturers hesitate between choosing a UV Cure Conveyor and a traditional UV curing oven. The key differences are outlined below:

| Criteria | UV Conveyor | UV Curing Oven |

|---|---|---|

| Operation mode | Continuous, automated | Batch-based, intermittent |

| Productivity | High, suitable for mass production | Moderate |

| Curing uniformity | Consistent across products | Dependent on loading method |

| Line integration | Easy integration | Less flexible |

| Long-term efficiency | Optimized cost per unit | Limited scalability |

From this comparison, it is clear that the UV Cure Conveyor is better suited for large-scale, automated production, while UV curing ovens are more appropriate for batch processing or small-volume production.

4. Practical Applications of the UV Cure Conveyor

Thanks to its flexibility and high curing efficiency, the UV Conveyor is widely used across various industries:

-

UV adhesive curing for electronic components and PCB assemblies

-

UV bonding for camera modules and sensors

-

UV ink curing in industrial and packaging printing

-

UV coating treatment for plastic, metal, and glass surfaces

-

Production lines requiring high speed and consistent repeatability

In particular, this system is ideal for factories that need to process large volumes of products daily while maintaining uniform quality standards.

UV LED Curing Conveyor Solution Consulting

Selecting the right UV Curing Conveyor depends on factors such as UV adhesive type, product dimensions, desired throughput, and installation conditions.

👉 For detailed consultation and the most suitable solution for your production line, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

UV Cure Conveyor

UV Cure Conveyor enables fast, uniform UV curing with high automation, ideal for modern production lines requiring speed and stability.

Product SKU: COUSZCVC003E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-27

Product In-Stock: InStock

4.99

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Great design and quality.