UV Chamber – An Enclosed, Safe, and Stable Curing Solution for Modern Manufacturing

In modern production lines, requirements for fast curing speed, high process stability, and especially operator safety are becoming top priorities. As a result, the UV Chamber is increasingly preferred by manufacturers as a replacement for traditional open UV curing systems. With its enclosed design, effective UV control, and easy integration into automation systems, the UV Curing Chamber not only improves production efficiency but also fully complies with industrial safety standards.

1. What Is a UV Chamber?

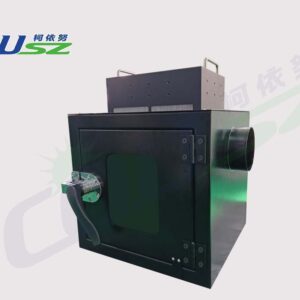

A UV Oven is a UV curing device that uses ultraviolet light to cure UV inks, UV adhesives, or UV coatings within a fully enclosed chamber. The entire UV exposure process takes place inside the chamber, significantly minimizing UV radiation leakage into the surrounding environment.

Unlike conventional open UV curing systems, a UV Oven focuses on:

-

Controlled UV exposure zones

-

Enhanced operator safety

-

Stable UV intensity and temperature control

Thanks to these features, the UV Cure Chamber is particularly suitable for factories with strict safety requirements or continuous long-term production.

2. Key Benefits of the UV Chamber

2.1. Superior Safety for Operators

The most significant advantage of a UV Curing Chamber lies in its enclosed structure. Protective housing, safety doors, and sensors help to:

-

Prevent direct UV radiation exposure

-

Reduce risks to eyes and skin

-

Minimize contact with heat and UV radiation

Compared to open-type UV flood curing machines, the UV Oven provides a safer and more professional working environment for operators.

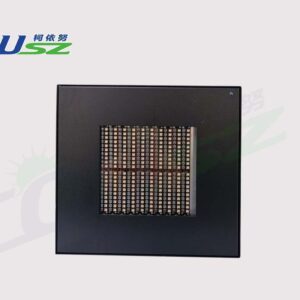

2.2. Stable and Uniform Curing Performance

With its enclosed curing chamber, the UV Chamber allows precise control of:

-

Exposure time

-

UV intensity

-

Internal chamber temperature

This ensures uniform curing results, reduces under-curing or over-curing defects, and significantly improves overall product quality.

2.3. Suitable for a Wide Range of Industrial Applications

The UV Cabinet is widely used in:

-

UV adhesive curing (electronics, camera modules, precision components)

-

Industrial printing

-

UV coating and surface finishing

-

Medical and optical device manufacturing

Its flexible design allows the UV Curing Chamber to be customized according to product size and specific production line requirements.

3. Comparison Between UV Chamber and Open UV Flood Curing Machines

3.1. Safety Level

UV Chamber:

-

Fully enclosed design

-

Protective housing, safety doors, and interlock mechanisms

-

Effective protection against direct UV exposure

Open UV Flood Curing Machines:

-

Typically open UV exposure systems

-

Higher risk of UV radiation leakage

-

Require additional manual shielding measures

👉 In terms of safety, the UV Curing Chamber clearly outperforms open UV flood curing machines and better meets modern factory safety standards.

3.2. Process Stability and Control

The UV Curing Cabinet enables synchronized control of all curing parameters within an enclosed environment, while open UV flood systems are more susceptible to external factors such as ambient light, airflow, and temperature fluctuations.

3.3. Production Line Integration

Thanks to its modular design, the UV Chamber can be easily integrated into:

-

Automated production lines

-

Conveyor systems

-

Closed-loop manufacturing processes

This helps manufacturers improve consistency and reduce reliance on manual operations.

4. When Should You Choose a UV Chamber?

A UV Oven is the ideal choice when manufacturers:

-

Require a high level of occupational safety

-

Operate continuous production with long-term stability requirements

-

Work with UV adhesives or inks requiring strict curing control

-

Aim to standardize production lines according to industrial standards

5. UV Chamber Solution Consultation with COUSZ

Selecting the right UV Cure Chamber is not only about power output or chamber size—it also depends on real-world applications, safety requirements, and future scalability.

👉 If you are looking for a safe, stable, and optimized UV Cure Chamber solution for your production line, contact us today:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

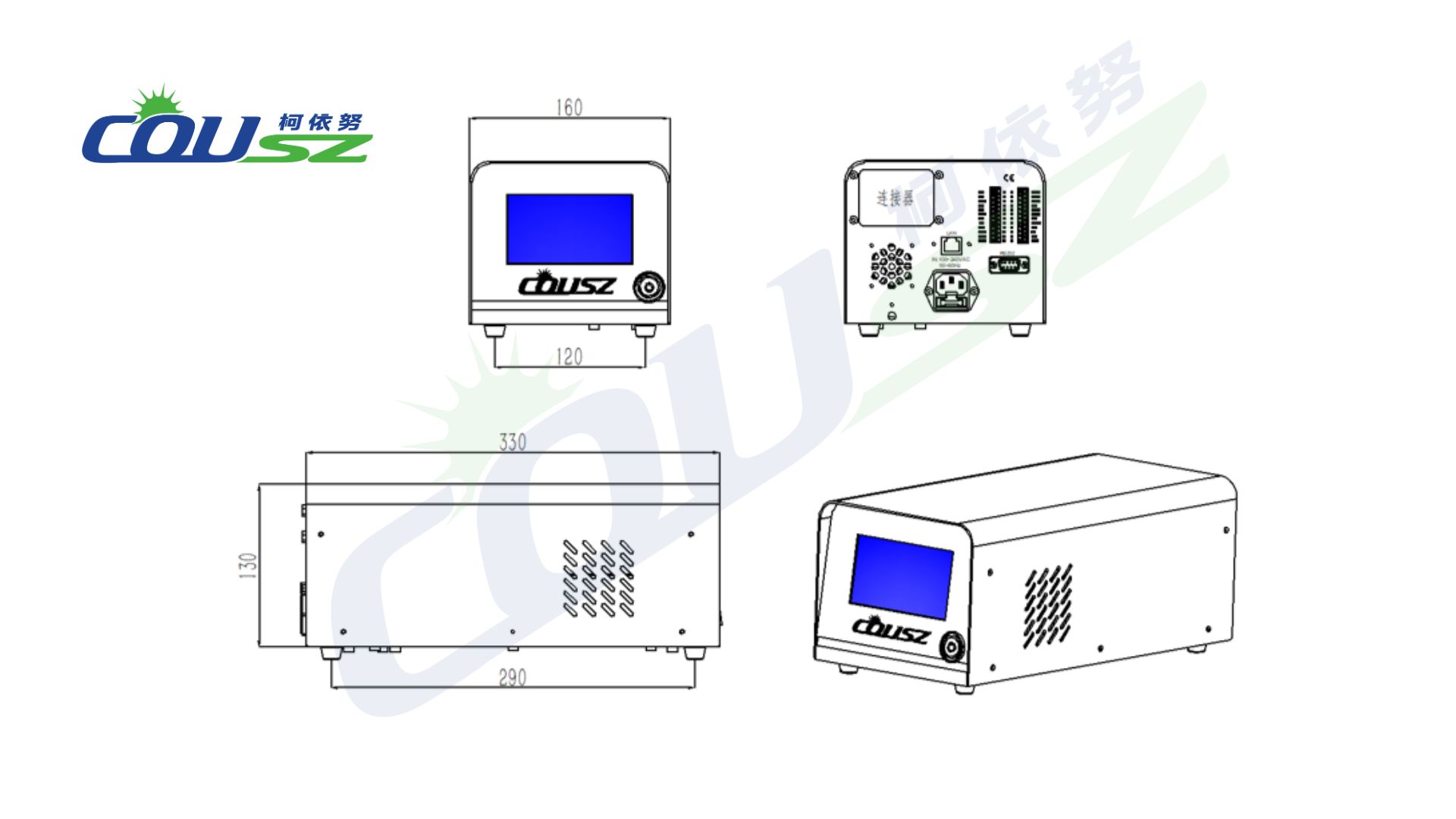

UV Chamber

UV Chamber provides enclosed, stable, and safe UV curing for modern manufacturing, improving efficiency while protecting operators.

Product SKU: COUSZCVO00E

Product Brand: COUSZ

Product Currency: VND

Product Price: 6868

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Easy to use and convenient.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com