Rotary Nozzle Plasma Cleaning System: A Breakthrough in Surface Cleaning Technology

In industries that demand ultra-clean surfaces—such as electronics, automotive, and medical manufacturing—the RC1000 Rotary Nozzle Plasma Cleaning System has become an essential solution. This article provides a comprehensive overview of its working principles, structure, and efficient operation.

1. Introduction to the RC1000 Rotary Nozzle Plasma Cleaning System

The RC1000 Rotary Nozzle Plasma Cleaning System utilizes cold plasma technology to clean and treat material surfaces. Unlike chemical or mechanical cleaning methods, this system generates an active plasma environment that effectively removes organic contaminants, dust, oil, and grease while significantly improving surface adhesion.

The RC1000 Rotary Nozzle Plasma Cleaning Machine is widely applied in electronic PCB cleaning, plastic mold preparation, and metal surface treatment prior to painting or adhesive bonding.

2. Structure of the RC1000 Rotary Nozzle Plasma Cleaning System

Understanding the system structure is crucial for efficient operation and maintenance. The RC1000 Rotary Nozzle Plasma Cleaning System consists of the following key components:

-

RF Generator: Generates high-frequency signals to excite and sustain plasma.

-

Plasma Chamber / Plasma Nozzle: The ionization zone where plasma is generated and directed onto the surface.

-

Gas Supply System: Supplies process gases such as compressed air, argon, oxygen, or mixed gases.

-

Cooling System: Ensures stable operation and prevents overheating.

-

Control Unit: Allows users to set and adjust power output, gas flow rate, and processing time.

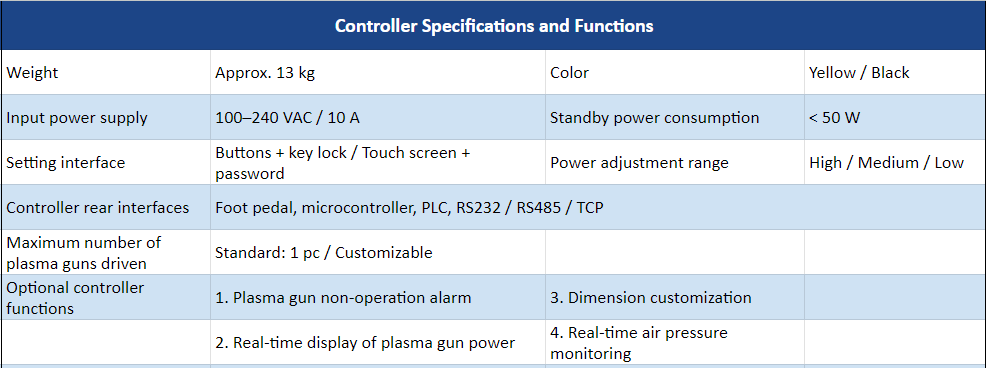

3. Technical Specifications of the RC1000 Rotary Nozzle Plasma Cleaning System

Below are the basic technical specifications of the RC1000 Rotary Nozzle Plasma Cleaning Machine:

4. Troubleshooting Guide for Common Issues

Below is a professional English technical translation suitable for user manuals or technical documentation of the RC1000 Rotary Nozzle Plasma Cleaner.

4.1. The system frequently stops during operation

Main causes:

Poor output circuit contact; high-voltage leakage; unreliable grounding; improper gas pressure; damaged load (plasma nozzle); power supply overheating; electrical grid interference.

Solutions:

Ensure secure connection between the high-voltage output cable and the load; inspect high-voltage cables for damage; verify reliable grounding; adjust gas supply pressure; replace the faulty load; check cooling fan operation and remove dust buildup; install a voltage stabilizer if necessary.

4.2. Low or weak output power

Main causes:

Low input voltage; abnormal plasma gun load; unstable gas pressure or flow rate.

Solutions:

Improve power supply conditions; check plasma gun cable connections for looseness or poor contact; clean or replace heavily oxidized electrodes; stabilize gas supply conditions.

👉 For detailed consultation, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

RC1000 Rotary Nozzle Plasma Cleaning System

Advanced RC1000 rotary nozzle plasma cleaning system for high-precision surface treatment in electronics, automotive, and medical industries.

Product SKU: ROTARY01E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com