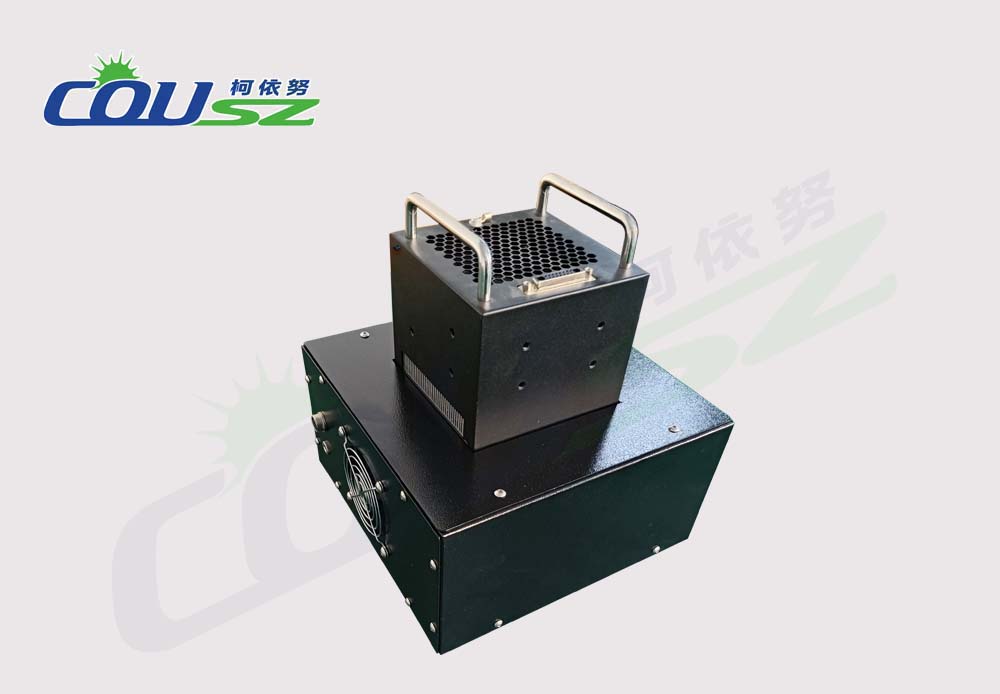

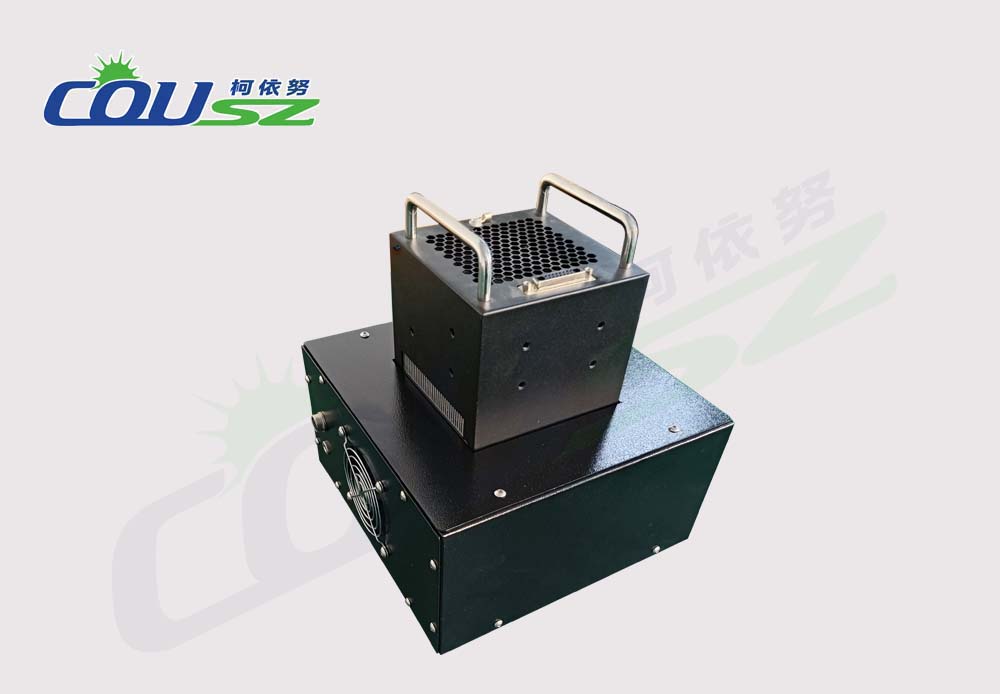

Mercury UV Light – A Traditional UV Source in Industrial Applications

In industrial UV curing processes, where high irradiation intensity, wide-area curing capability, and long-term operational stability are top priorities, Mercury UV Light remains a familiar choice for many production lines. Although UV LED technology continues to advance rapidly, Mercury Lamp still plays an important role in traditional adhesive curing, UV ink curing, and protective coating applications.

1. What Is a Mercury UV Light?

Mercury UV Light is a UV light source that uses high-pressure mercury vapor to generate ultraviolet radiation when energized by an electrical current. During operation, mercury atoms are excited and emit UV radiation at multiple wavelengths, including 254 nm, 313 nm, 365 nm, and 405 nm.

Thanks to its broad wavelength spectrum, Mercury Lamp can activate various photoinitiators found in UV adhesives, UV inks, and UV coatings. This is why it was regarded as a standard solution in industrial UV curing technology for decades.

2. Advantages of Mercury UV Light

In traditional UV curing systems, Mercury UV Light offers several notable advantages:

-

High UV intensity, suitable for thick adhesive layers and protective coatings

-

Broad spectral output, compatible with a wide range of UV adhesive formulations

-

Wide-area curing capability, ideal for PCB boards and large surfaces

-

Proven and mature technology, easy to operate and maintain

-

Reasonable initial investment cost for conventional production lines

These advantages explain why Mercury UV Lamp continues to be used in many factories with stable, well-established UV curing systems.

3. Practical Applications of Mercury UV Light

Today, Mercury Lamp is widely applied in the following areas:

-

UV adhesive curing on PCB boards

-

Curing protective coatings for electronic components

-

UV ink curing in industrial printing

-

UV coating on plastic, metal, and glass surfaces

-

Production lines requiring uniform curing over large areas

This type of UV light source is especially suitable for UV curing machines that were originally designed for mercury-based technology, helping manufacturers minimize retrofit and upgrade costs.

4. When Should Alternative Solutions Be Considered?

Despite its strengths, Mercury UV Light also has limitations, such as high heat generation, higher power consumption, and a shorter lifespan compared to UV LED systems. Therefore, in applications that prioritize energy efficiency, precise wavelength control, or automation integration, manufacturers may consider switching to modern UV LED curing solutions.

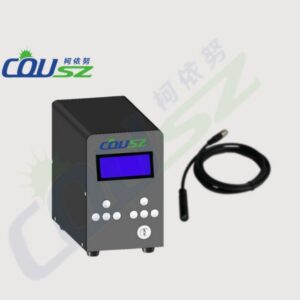

UV Adhesive Curing Solutions by COUSZ

Professional UV Curing Consultation for Your Business

Choosing between Mercury Light and other UV curing solutions depends on the type of adhesive, production process, installation space, and long-term cost optimization strategy.

👉 For detailed consultation and the most suitable UV curing solution, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

Mercury UV Light

Mercury UV Light is a traditional UV curing source offering high intensity and a broad spectrum, widely used in adhesive, ink, and coating curing.

Product SKU: COUSZCVC05E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

No complaints at all.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com