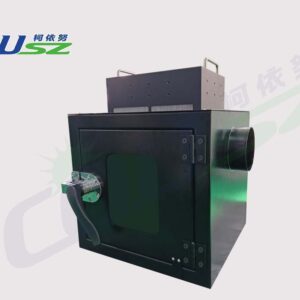

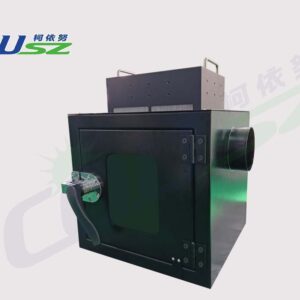

Mercury Lamp – A Traditional UV Adhesive Curing Solution for Industry

In many electronics and industrial production lines, requirements for wide-area adhesive curing, high curing strength, and long-term process stability remain critical. The Mercury Lamp is one of the most established UV curing technologies, widely used for many years—especially in PCB manufacturing, protective coating of components, and industrial printing.

Despite the rapid development of UV LED technology, the Mercury Bulb still maintains a certain position thanks to its strong UV output, broad wavelength spectrum, and effective curing performance for various UV adhesives.

1. What Is a Mercury Lamp?

A Mercury Bulb is a UV curing device that uses a high-pressure mercury bulb to emit ultraviolet (UV) radiation, activating photochemical reactions in UV adhesives. Thanks to its broad wavelength spectrum—typically including 254 nm, 313 nm, 365 nm, 405 nm, and more—the system can cure a wide range of UV adhesives and coatings with different thicknesses.

When UV adhesive is exposed to UV radiation from a mercury system, the photoinitiators within the adhesive are activated, triggering a polymerization reaction that rapidly forms a solid, durable adhesive layer. This is why Mercury Bulb systems were once a standard solution in many manufacturing plants.

2. Advantages of the Mercury Lamp

In traditional applications, the Mercury Bulb offers several notable advantages:

-

High UV intensity: Suitable for thick adhesive layers and protective coatings

-

Broad wavelength spectrum: Compatible with various UV adhesive formulations

-

Wide-area curing capability: Effective for large surfaces such as PCB boards

-

Mature technology: Easy operation and straightforward component replacement

-

Reasonable initial investment cost for traditional production systems

Thanks to these advantages, Mercury systems continue to be used in many stable, long-established production lines.

3. Limitations of the Mercury Lamp

Alongside its benefits, the Mercury Bulb also has several limitations that manufacturers should consider:

-

High heat generation, which may affect heat-sensitive materials

-

Higher energy consumption compared to UV LED systems

-

Shorter lamp lifespan, requiring periodic replacement

-

Long warm-up time, not suitable for instant on/off operation

-

Limited wavelength control for specialized adhesive formulations

These limitations are key reasons why many manufacturers are gradually transitioning to modern UV LED curing solutions.

4. Typical Applications of the Mercury Lamp

In real-world production environments, the Mercury Lamp is commonly used for:

-

Protective coating curing for PCB boards

-

Wide-area UV coating curing

-

UV adhesive curing in industrial printing

-

Protective coating of electronic components

-

Applications requiring uniform curing over large surfaces

This equipment is especially suitable for traditional production lines already designed around mercury lamp technology.

5. When Should UV LED Curing Solutions Be Considered?

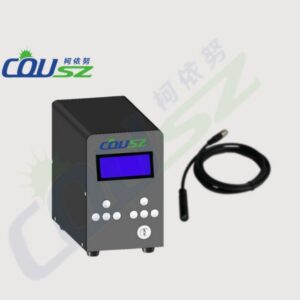

For manufacturers aiming to reduce energy consumption, minimize heat, and achieve precise curing control, switching to UV LED adhesive curing machines has become an inevitable trend. UV LED solutions offer:

-

Precise wavelength selection for specific adhesives

-

Lower power consumption

-

Longer light source lifespan

-

Easy integration with automation systems and PLC control

6. UV Adhesive Curing Solution Consultation with Ms. Yuna

Choosing between a Mercury Lamp and a UV LED curing system depends on adhesive type, technical requirements, installation space, and long-term cost optimization strategy.

👉 For professional consultation and the most suitable UV adhesive curing solution for your production line, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

Mercury Lamp

Mercury Lamp is a traditional UV curing solution offering high intensity and wide-area curing for PCB coating and industrial applications.

Product SKU: COUSZCVC04E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Excellent overall experience.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com