LED UV Spot Curing System H86F – An Optimal Solution for Modern Production Lines

As industries such as electronics manufacturing, camera modules, precision components, and engineering materials continue to demand higher stability, repeatability, and continuous operation, the LED UV Spot Curing System H86F has become a preferred choice for many factories. Beyond delivering precise UV curing performance, this system is specifically optimized for automated production environments and long-hour operation.

This article provides a comprehensive overview of the system structure, key advantages, a comparison between the H86F and H56 models, and explains why the H86F is particularly well suited for modern production lines.

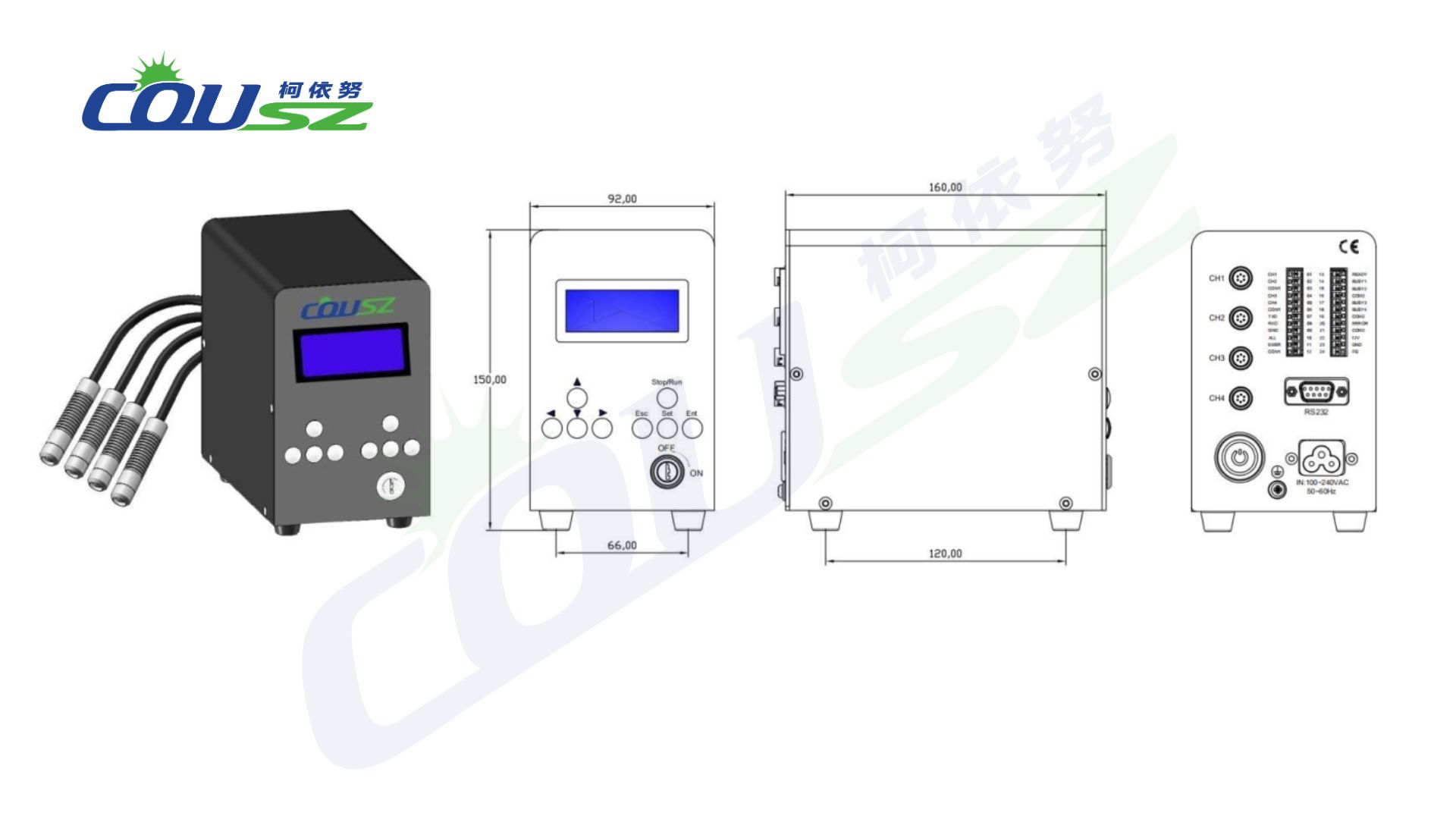

1. Overview of the LED UV Spot Curing System H86F

The LED UV Spot Curing System H86F is a point-type UV LED curing solution designed to focus UV energy precisely on defined target areas. Unlike flood-type UV curing systems, the LED UV Spot Curing System enables accurate control of the curing zone, significantly reducing thermal impact on surrounding areas.

With an 86 mm lamp head design and an integrated active cooling fan, the H86F is especially suitable for applications that require continuous, high-intensity, and stable operation over extended periods.

2. Structure and Lamp Head Design of the H86F

The most distinctive feature of the LED UV Spot Curing System H86F lies in its lamp head design:

-

Lamp head length: 86 mm

-

Integrated cooling fan for efficient temperature control

-

Robust structure suitable for fixed installation on robots, jigs, or conveyor systems

Thanks to its effective heat dissipation, the H86F lamp head maintains stable irradiation intensity even during multi-shift continuous operation. This minimizes LED power degradation and significantly extends the system’s service life.

3. Comparison Between the LED UV Spot Curing System H86F and H56

When selecting a LED UV Spot Curing System, many manufacturers compare the H86F and H56 models. Below is a clear comparison:

Lamp head length

- H86F: 86 mm lamp head, suitable for open environments with sufficient installation space

- H56: 56 mm lamp head, ideal for narrow gaps and confined installation areas

Continuous operation capability

- H86F: Equipped with an integrated cooling fan, suitable for 24/7 continuous operation

- H56: More suitable for intermittent operation; not recommended for prolonged high thermal loads

As a result, the LED UV Spot Curing System H86F is the ideal choice for factories that prioritize long-term stability and sustained productivity.

4. Advanced Features of the LED UV Spot Curing System H86F

Intelligent alarm and feedback system

The system integrates LED lamp fault detection and real-time operating status output. This allows the LED UV Spot Curing System H86F to coordinate seamlessly with robots, PLCs, conveyors, and other automated equipment on the production line.

Poka-yoke (error-proofing) function

The control interface supports parameter and controller status locking, preventing operators from accidentally stopping UV irradiation prematurely. This ensures that UV adhesives always receive sufficient energy for complete curing and consistent product quality.

Layered irradiation technology

The H86F supports multiple irradiation modes, including step and pulse control. This technology helps manage the curing process, suppress material shrinkage and deformation, and is particularly effective for UV adhesives used on engineering plastics and heat-sensitive components.

Durable and clean design

The housing is made of sealed die-cast aluminum, offering excellent dust resistance and corrosion protection over time. This design enhances durability while meeting the cleanliness requirements of industrial production environments.

5. Why Choose the LED UV Spot Curing System H86F?

Compared with many other point-type UV curing solutions on the market, the H86F offers clear advantages:

- Long lamp head with excellent heat dissipation for stable long-term operation

- Strong support for automation and PLC integration

- Reduced operational errors through Poka-yoke functionality

- Improved adhesive quality through layered irradiation control

- Robust design suitable for demanding industrial environments

6. Conclusion

In modern manufacturing, where precision and operational stability are critical, the LED UV Spot Curing System H86F is a reliable solution for companies seeking high-performance, durable, and easily integrated UV curing equipment. With its 86 mm lamp head, integrated cooling fan, and intelligent control features, the H86F not only enhances product quality but also helps optimize long-term operating costs.

Contact Ms Yuna for technical support!

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com

LED UV Spot Curing System

Discover the LED UV Spot Curing System H86F with 86mm lamp head, active cooling, smart control, and stable performance for modern automated production lines.

Product SKU: COUSZCVDH86FE

Product Brand: COUSZ

Product Currency: VND

Product Price: 6888

Price Valid Until: 2025-12-31

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Love it! Will buy again.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com