Plasma Surface Cleaner – An Optimal Solution for Manufacturing

The Jet Nozzle Plasma Surface Cleaner is rapidly becoming an essential technology in modern production lines, where high requirements for surface cleanliness, adhesion strength, and process stability are critical. With its precise treatment capability, chemical-free operation, and easy automation, this system helps manufacturers improve product quality while optimizing long-term operating costs.

1. Introduction to the Jet Nozzle Plasma Surface Cleaner

The plasma treatment machine utilizes low-temperature plasma technology to perform micro-level cleaning and surface activation prior to processes such as adhesive bonding, coating, printing, or assembly. The treatment effectively removes fine dust, oil residues, organic contaminants, and oxidation layers that are difficult to eliminate using conventional mechanical or chemical methods.

Unlike traditional surface treatment approaches, plasma surface cleaning does not require chemical solvents, generates no wastewater, and does not deform materials. This makes the system well aligned with green manufacturing trends and workplace safety requirements.

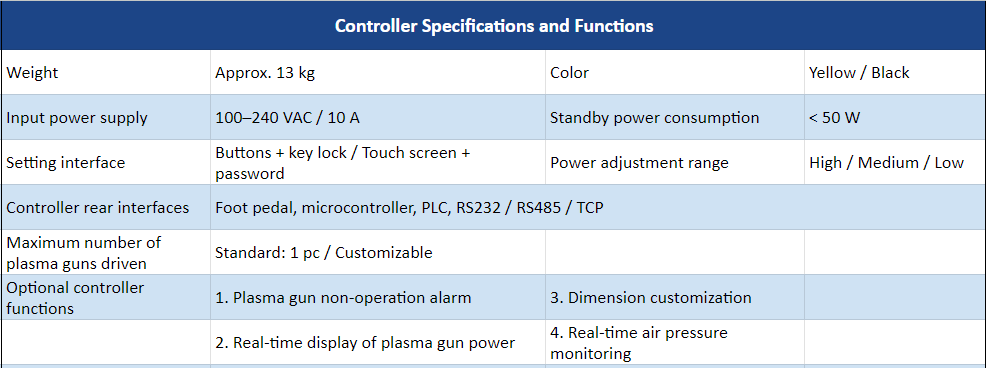

2. Technical Specifications of the Jet Nozzle Plasma Surface Cleaner (Reference)

Depending on configuration and application requirements, the technical specifications of the plasma treatment equipment may vary. Typical parameters include:

Thanks to its flexible design, the plasma surface treatment systems can meet diverse surface treatment demands in large-scale industrial manufacturing environments.

3. Working Principle of the Jet Nozzle Plasma Surface Cleaner

The Jet Nozzle Plasma Surface Cleaner operates by generating plasma from process gases under precisely controlled power and pressure conditions. When plasma interacts with the material surface, high-energy particles:

-

Break down organic contaminant bonds

-

Perform molecular-level micro cleaning

-

Create active functional groups, increasing surface energy

As a result, the treated surface becomes more receptive to adhesives, inks, and coatings, significantly improving adhesion strength and long-term process stability.

4. Comparison Between the Jet Nozzle Plasma Surface Cleaner and Vacuum Plasma Systems

When selecting surface treatment technologies, manufacturers often compare atmospheric plasma systems with vacuum plasma solutions. The key differences include:

Industrial plasma (atmospheric plasma):

-

No vacuum chamber required

-

Continuous processing, easy inline integration

-

Ideal for high-speed, mass production

Vacuum plasma:

-

Requires sealed chambers and vacuum systems

-

Batch-based processing

-

Suitable for R&D or specialized surface treatments

For modern industrial manufacturing needs, the jet nozzle plasma surface treatment machine is often preferred due to its flexibility, high efficiency, and lower operating costs.

5. Industrial Applications of the Jet Nozzle Plasma Surface Cleaner

The Jet Nozzle Plasma Surface Cleaner is widely used across various industries, including:

-

Electronics and semiconductor components

-

Engineering plastics, rubber, and composites

-

Automotive and supporting industries

-

Printing, packaging, and industrial labeling

With its stable and precise performance, the system helps manufacturers reduce delamination defects and enhance final product quality.

Consultation – Jet Nozzle Plasma Cleaner

Are you looking for a plasma surface treatment solution suitable for your current production line, or do you need expert advice tailored to specific materials and applications?

👉 Contact Ms. Yuna for in-depth technical consultation, sample testing support, and fast quotation:

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

Jet Nozzle Plasma Surface Cleaner

Jet Nozzle Plasma Surface Cleaner enhances surface cleanliness and adhesion, enabling stable, chemical-free surface treatment in production lines.

Product SKU: JETPLASMA05E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-31

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com