Jet Nozzle Plasma Surface Treatment Machine – A Modern Surface Treatment Solution

In modern manufacturing industries, requirements for adhesion strength, surface cleanliness, and process stability are becoming increasingly stringent. The Jet Nozzle Plasma Surface Treatment Machine DC500S has been developed as an advanced technological solution that helps manufacturers improve product quality, reduce reliance on chemical agents, and optimize long-term operating costs.

1. Introduction to the Jet Nozzle Plasma Surface Treatment Machine DC500S

The Jet Nozzle Plasma Surface Treatment Machine DC500S is a surface treatment system that utilizes low-temperature plasma technology to perform micro-level cleaning and surface activation before processes such as adhesive bonding, coating, printing, or assembly.

Unlike conventional methods, plasma treatment equipment does not use chemical solvents, does not cause abrasion, and does not deform materials. As a result, this machine is particularly suitable for electronics, engineering plastics, industrial components, and applications requiring high precision and stable surface quality.

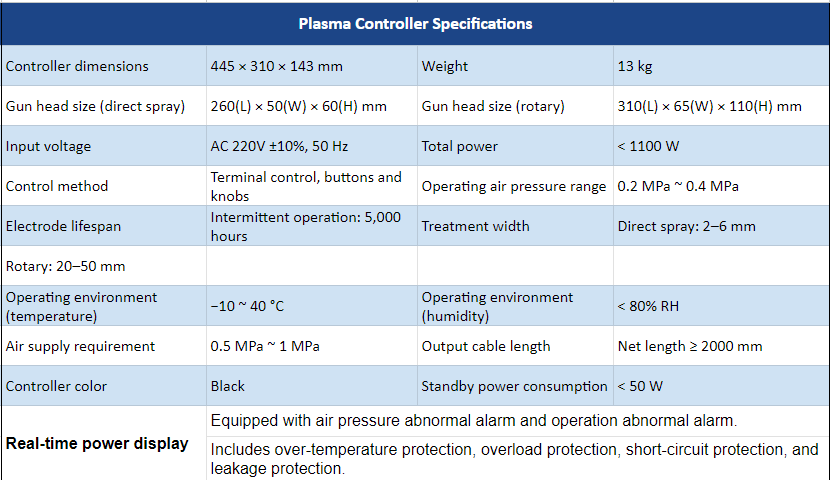

2. Technical Specifications of the Jet Nozzle Plasma Surface Treatment Machine DC500S

Understanding the technical specifications of a plasma treatment machine enables manufacturers to select equipment that best fits their production lines:

3. Comparison Between the Jet Nozzle Plasma Surface Treatment Machine DC500S and Chemical Primer Treatment

Below is a detailed comparison between chemical Primer treatment and plasma surface treatment for improving surface adhesion.

Although both methods aim to increase surface energy and enhance chemical bonding, their mechanisms and practical applications differ significantly.

3.1 Similarities

-

Purpose: Both methods increase surface energy, making the surface more receptive to liquids such as adhesives, inks, and coatings.

-

Bonding mechanism: Both aim to create functional chemical groups on the surface to form stronger bonds with subsequent layers.

-

Applications: Commonly used for difficult-to-bond materials such as plastics (PP, PE, PTFE), polished metals, and composites.

3.2 Differences

| Criteria | Chemical Primer Method | Plasma Treatment Method |

|---|---|---|

| Nature | Chemical process, adds an intermediate material layer | Physical–chemical process, directly modifies surface molecules |

| Thickness | Forms a thin film (a few microns) | No change to physical dimensions (atomic-level effect only) |

| Treatment mechanism | Uses solvents and polymers to “prime” the surface | Uses charged particles and radicals to remove contaminants and create new functional groups |

| Environment & safety | Often contains flammable organic solvents, requires ventilation and PPE | Environmentally friendly, no hazardous chemicals, no liquid waste |

| Durability over time | Long-lasting once dried before the next process | Shorter-term effect; surface activation may diminish over hours or days, requiring immediate bonding |

| Initial investment cost | Low, simple spraying or brushing tools | Higher, requires plasma generator, jet nozzle, and control system |

| Operating cost | High due to ongoing primer consumption | Low, mainly electricity and compressed air |

| Automation capability | Difficult to ensure consistency with manual operation | Highly automated, easy integration into mass production lines |

Thanks to these advantages, plasma treatment machines are gradually replacing chemical primers in many modern production lines.

4. Why Invest in the Jet Nozzle Plasma Surface Treatment Machine DC500S?

-

Significantly improves adhesion of adhesives, coatings, and printing inks

-

Reduces delamination and enhances final product quality

-

Eliminates chemical primers, ensuring operator safety

-

Aligns with green manufacturing and automation trends

The Jet Nozzle Plasma Surface Treatment Machine DC500S is not just a piece of equipment—it is a comprehensive upgrade for industrial surface treatment processes.

CTA – Contact Us for Consultation

Are you looking for a plasma surface treatment solution that is safe, efficient, and easy to integrate into your production line?

👉 Contact Ms. Yuna for in-depth technical consultation, sample testing, and fast quotation for plasma surface treatment machines:

-

📞 Hotline: +84 965 535 348

-

📧 Email: sales03@cousz.com

Jet Nozzle Plasma Surface Treatment Machine

Jet Nozzle Plasma Surface Treatment Machine DC500S enhances adhesion and surface cleanliness, replacing chemical primers in manufacturing.

Product SKU: JETPLASMA04E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-31

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com