The UV Flood Lamp – The Optimal Technological Solution for Production Lines

In the context of modern industrial production, the rapid and precise curing of adhesives, printing inks, or coatings is a critical factor determining output productivity and product quality. The UV flood lamp has become an indispensable device across many industries, from electronic component assembly and packaging printing to household goods and medical device manufacturing.

This article will delve into a popular model of UV flood lamp with a standard curing area of 30×30 cm, while also providing a comprehensive comparative overview of two leading heat dissipation technologies: fan cooling and water cooling.

1. Overview of the CYM3030 UV Flood Lamp

A 30×30 cm curing area is considered the gold standard in many industrial applications. A UV flood lamp with this specification typically integrates a UV LED array system, evenly arranged to ensure uniform irradiance distribution across the material surface.

A key advantage of this lamp model is its flexibility. It can be easily integrated into automated conveyor lines or used as a semi-automatic, fixed curing station. Thanks to the standardized curing area, programming cure time, adjusting power, and maintenance become simpler, making it suitable for both small and medium-sized factories seeking an effective, stable UV flood lamp solution.

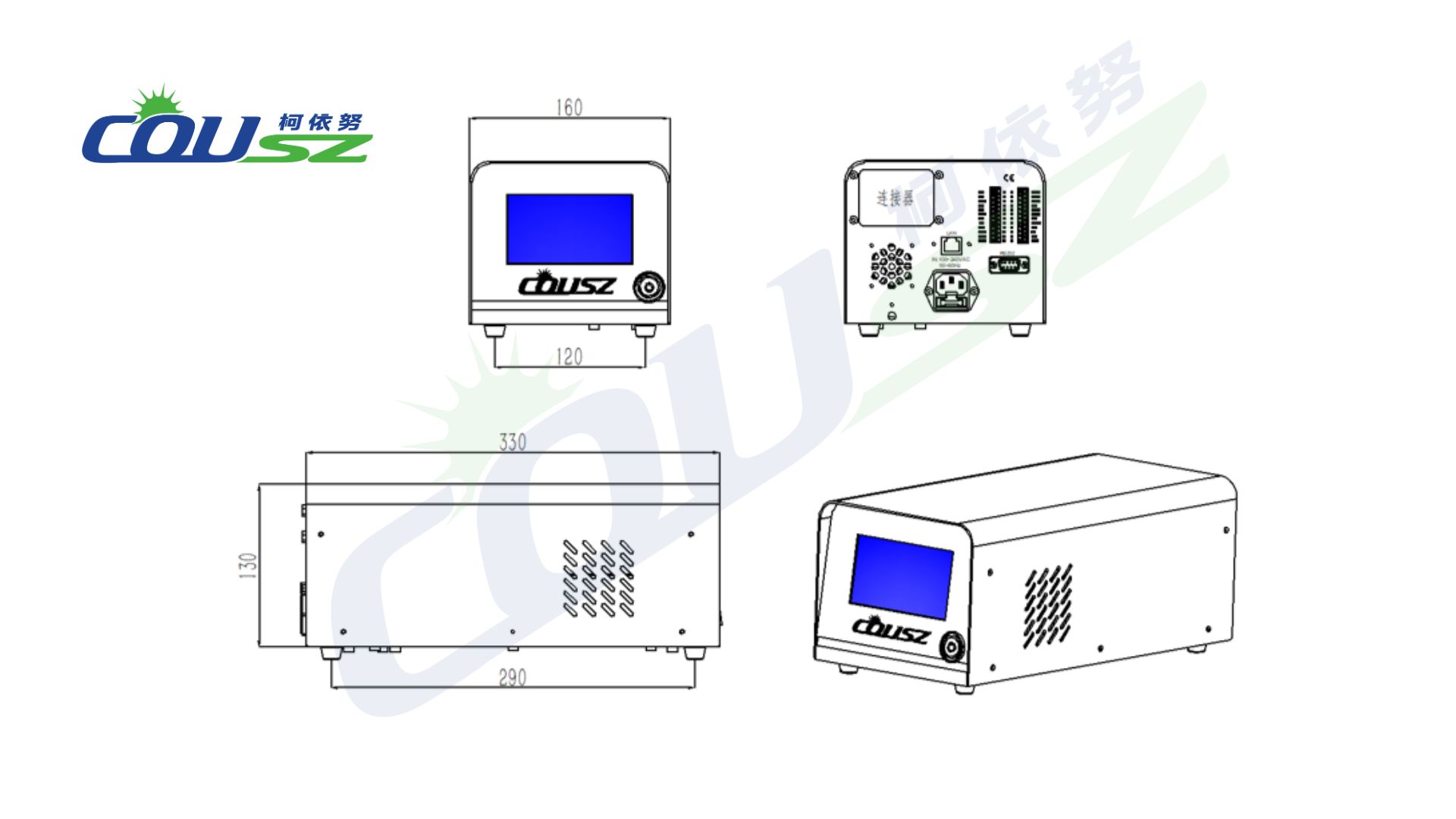

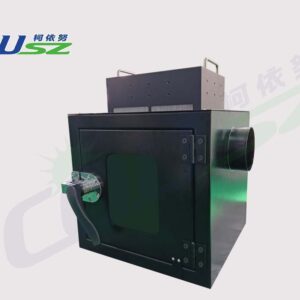

The CYM3030 UV Flood Lamp consists of two main components:

2. The Technology Face-off: Fan-Cooled vs. Water-Cooled UV Flood Lamps

The most crucial factor determining the performance and lifespan of a UV flood lamp is its heat dissipation system. The heat generated by UV lamps is substantial; if not properly controlled, it leads to reduced lamp lifespan, unstable UV intensity, and even component damage.

The table below provides a detailed comparison between the two prevalent technologies:

| Criterion | Fan-Cooled UV Flood Lamp | Water-Cooled UV Flood Lamp |

|---|---|---|

| Operating Principle | Uses one or more high-power fans to blow air across heatsinks attached to the lamp/LED board. | Uses a circulating liquid system (typically deionized water) flowing through channels or metal blocks in direct contact with the heat source. |

| Cooling Efficiency | Good, suitable for small to medium applications, intermittent curing cycles. | Superior, with exceptional heat absorption and conduction, suitable for 24/7 continuous operation, high power output. |

| Investment & Maintenance Cost | Lower. Simple structure, easy maintenance and fan replacement. | Higher. Complex system requiring periodic maintenance of pipes, pumps, reservoirs, and coolant. |

| Stability & Lifespan | Stable under average load conditions. Lamp lifespan may be affected by continuous high-temperature operation. | Extremely stable. Maintains ideal operating temperature for LEDs, thereby extending lamp lifespan (up to 20,000-30,000 hours). |

| Application Scope | Ideal for small workshops, laboratories, or production lines with breaks between batches. | The essential choice for large factories, highly automated production lines requiring continuous curing with consistent output quality. |

Selection Conclusion:

-

If you need a UV flood lamp on an optimized budget, for applications not requiring 24/7 operation, the fan-cooled model is an economical and effective choice.

-

Conversely, if your business operates in a field with stringent demands on productivity, consistent quality, and minimizing maintenance downtime, investing in a water-cooled UV flood lamp system is a strategic decision for long-term efficiency.

3. Guide to Choosing the Right UV Flood Lamp

Beyond deciding on the cooling technology, when selecting a UV flood lamp, you should consider the following factors:

- Suitable Wavelength: Choose the appropriate wavelength range (365nm, 385nm, 395nm, 405nm) based on the adhesive/ink type (UV-A, UV-B, UV-C).

- Lamp Power (W/cm² or mW/cm²): This intensity determines the curing speed and depth. Reference the technical requirements of your material.

- Adjustability of Conveyor Speed/Intensity: Allows for process optimization for specific products.

- Uniformity of the Curing Area: Ensures products receive consistent UV intensity at every point within the 30×30 cm area.

In summary, a UV flood lamp with a 30×30 cm curing area is a powerful ally in industrial production. Understanding the difference between fan and water cooling technologies will help businesses make informed investment decisions, balancing cost, production needs, and sustainable development goals.

Ready to Optimize Your Production Line?

Contact us today for detailed consultation and a competitive quote!

📞 Call Now: +84 965 535 348

✉️ Email: sales03@cousz.com

OR LEAVE YOUR INFORMATION, and we will contact you within 24 hours!

CYM3030 UV Flood Lamp

Discover the CYM3030 UV Flood Lamp with 30x30cm coverage. Compare fan-cooled vs water-cooled technology. Optimize your UV curing process. Get expert advice and quote today!

Product SKU: COUSZCYM3030E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-31

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Quality you can trust.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com