CYM2002 UV Curing Equipment – An Optimal UV Curing Solution for Manufacturing

As industrial manufacturing increasingly demands higher speed, precision, and operational stability, traditional curing methods are gradually revealing their limitations. CYM2002 UV Curing Equipment is introduced as a professional UV light curing system, enabling manufacturers to optimize adhesive curing, surface coating, and component assembly in accordance with modern industrial standards.

1. Overview of CYM2002 UV Curing Equipment

CYM2002 UV Curing Equipment utilizes ultraviolet light energy to initiate polymerization reactions in adhesives and other light-curable materials. The system is specifically designed to meet stringent requirements in industries such as electronics, camera modules, medical devices, and precision component manufacturing.

CYM2002 UV Curing Machine allows precise control of light intensity and curing time, ensuring uniform curing quality, minimizing defects, and improving product durability. With its flexible design, the equipment can be easily integrated into automated or semi-automated production lines, making it suitable for a wide range of factory setups.

2. Structure of CYM2002 UV Curing Equipment

Structurally, CYM2002 UV Curing System is composed of key components that ensure stable and safe operation:

-

High-power UV light source: Uses UV lamps or UV LED modules with optimized wavelengths suitable for various curing adhesives and coatings.

-

Enclosed curing chamber: A robust design with UV shielding to protect operators and reduce energy loss.

-

Central control system: Enables precise adjustment of curing time and intensity, with program storage for repetitive processes.

-

Reflectors and optical lenses: Ensure uniform UV light distribution across the product surface, maximizing curing efficiency.

The seamless integration of these components guarantees long-term stability, extended service life, and reduced maintenance costs.

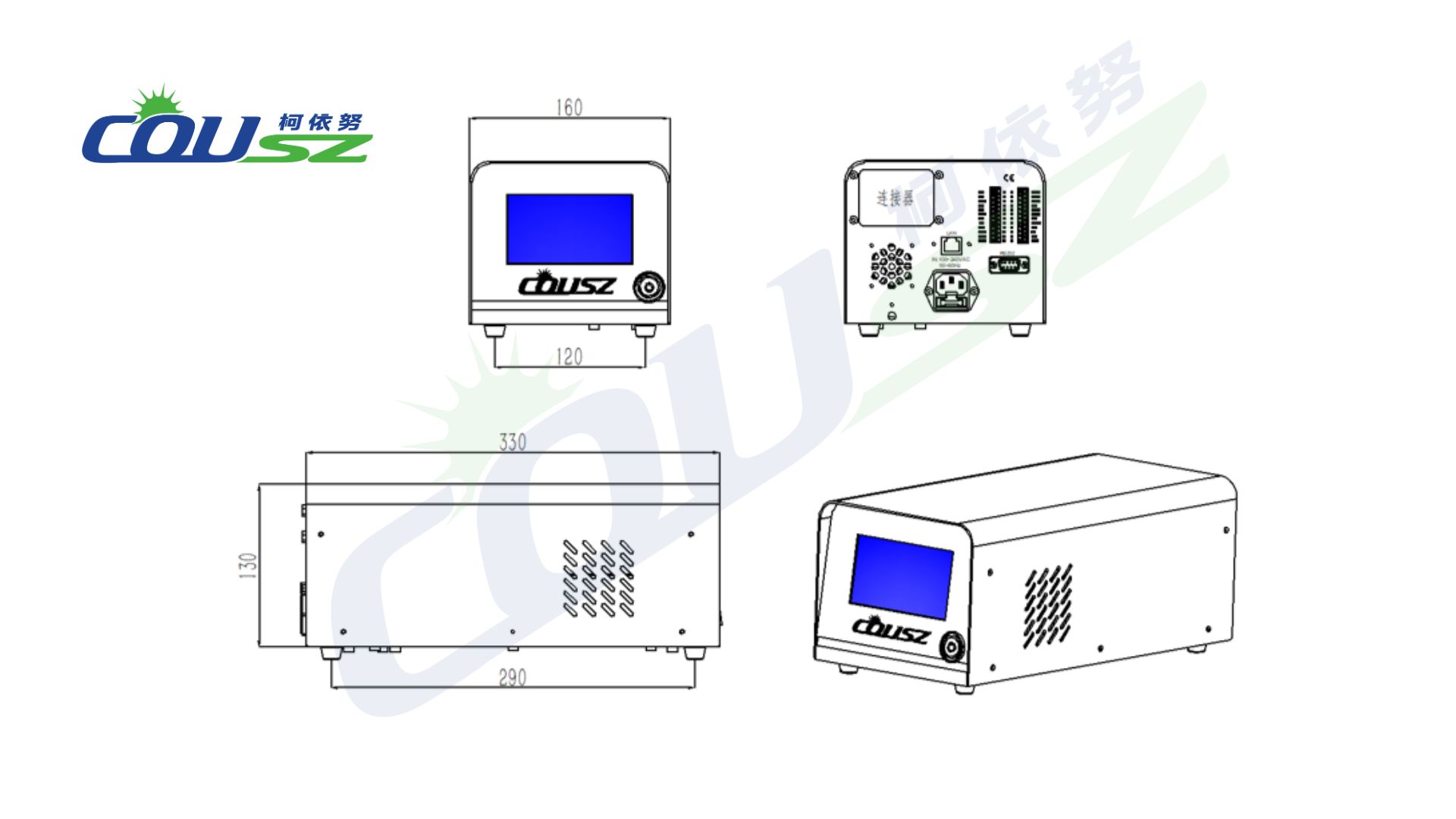

3. Technical Specifications of the CYM2002 UV Curing Controller

| Item | Specification | Item | Specification |

|---|---|---|---|

| Dimensions (mm) | L330 × W160 × H130 mm | Power | 50 W |

| Cooling method | Fan cooling | Input voltage | 100–240 V AC, 50–60 Hz |

| Weight / Material | Approx. 3.5 kg, metal housing | Output power | 10%–100% |

| Parameter lock | Integrated password protection for advanced settings | Display & setting | Touchscreen; time & intensity |

| Number of LED light sources | 1–4 units | Control | Foot pedal, SCM, PLC, RS232 / RS485 / TCP |

| Alarm | Alerts for over-temperature, system faults, etc. | Operating time | Accumulated operating time recording |

4. Benefits of Applying CYM2002 UV Curing Equipment

Investing in CYM2002 UV Curing Equipment offers significant advantages for manufacturers:

-

Shortened curing time and increased production throughput

-

Stable curing quality with reduced defects and scrap rates

-

Lower energy consumption compared to thermal curing methods

-

Easy integration with existing automation systems

-

Enhanced safety and improved environmental performance

These benefits explain why UV curing solutions are increasingly preferred in high-tech manufacturing industries.

For businesses seeking a stable, energy-efficient, and integration-friendly UV curing solution, CYM2002 UV Curing Equipment is a highly competitive choice for modern production systems.

👉 For detailed consultation, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

CYM2002 UV Curing Equipment

CYM2002 UV Curing Equipment delivers fast, stable, and energy-efficient UV curing for electronics, precision parts, and modern production lines.

Product SKU: COUSZCYM2002E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2026-01-14

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

👉 For detailed consultation, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com