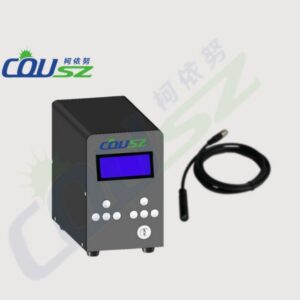

CYD8 Spot UV Curing Equipment – Precision Curing Control for Modern Manufacturing

In industries such as electronics manufacturing, camera modules, precision components, medical devices, and advanced engineering materials, requirements for curing accuracy, process stability, and repeatability are becoming increasingly stringent. To meet these demands, Spot UV Curing Equipment with touch-screen control has emerged as a preferred solution for modern production environments.

By combining focused UV spot curing technology with an intelligent touch interface, this equipment not only improves curing efficiency but also significantly reduces operational errors and enhances overall product quality. Among these solutions, CYD8 Spot UV Curing Equipment stands out as a reliable and scalable choice for automated production lines.

1. Overview of Spot UV Curing Equipment

Spot UV Curing Equipment uses UV LED light sources to concentrate ultraviolet energy precisely onto a defined point or small curing area. This enables fast, controlled, and repeatable curing of UV adhesives without exposing surrounding components to unnecessary heat.

The touch-screen version further enhances usability by allowing operators to configure curing parameters, monitor operating status, and manage alarms through a clear and intuitive interface. Compared with traditional button-controlled systems, touch-controlled Spot UV Curing Equipment provides a more advanced user experience and meets the traceability and process control requirements of professional manufacturing facilities.

With its optimized design, CYD8 Spot UV Curing Equipment is particularly suitable for applications that require consistent curing quality and seamless integration into automated systems.

2. System Structure and Operating Principle

A typical touch-controlled Spot UV Curing Equipment system consists of the following core components:

- Central controller with integrated touch screen

- UV LED spot light source

- One or multiple UV curing lamp heads

- Cooling system (air-cooled or water-cooled)

- Signal interfaces for PLCs, robots, and external equipment

The operating principle is based on precise control of UV irradiation time, intensity, and curing mode. The controller sends commands to the UV LED source according to predefined parameters, directing UV energy exactly to the adhesive curing location. This allows Spot UV Curing Equipment to achieve high curing efficiency while minimizing thermal impact on sensitive surrounding materials.

3. Key Advantages of Touch-Controlled Spot UV Curing Equipment

3.1 Intuitive and user-friendly operation

The touch screen interface enables fast configuration and clear visualization of curing time, lamp head status, and system alarms. This reduces dependency on operator experience and minimizes the risk of incorrect settings during production.

3.2 Precise curing process control

Users can set curing time with high accuracy, making the system ideal for applications requiring strict repeatability. This precision is a major advantage of CYD8 Spot UV Curing Equipment in high-volume production lines.

3.3 Seamless automation integration

The system supports digital input and output signals, allowing easy connection to PLCs, robotic arms, and conveyor systems. This makes Spot UV Curing Equipment fully compatible with smart factory and automated manufacturing concepts.

3.4 Reduced operational errors and improved product quality

With parameter-locking functions and controlled operation logic, touch-controlled Spot UV Curing Equipment ensures that UV adhesives receive sufficient irradiation energy, resulting in stable curing quality and reduced defect rates.

4. Comparison: Touch-Screen vs. Non-Touch Spot UV Curing Equipment

Control interface

- Touch-screen models: intuitive operation, fast learning curve, clear parameter visibility

- Non-touch models: mechanical buttons, higher reliance on operator experience

Parameter setting and monitoring

- Touch-screen models: comprehensive status display and clear alarm notifications

- Non-touch models: limited information display

Suitability for automation

- Touch-screen models: ideal for modern, large-scale automated production lines

- Non-touch models: suitable for simple applications or small-scale operations

Overall, touch-controlled Spot UV Curing Equipment provides long-term benefits in efficiency, process control, and production management.

5. Reference Technical Specifications

- Operating voltage: 100 ~ 240 VAC

- Frequency: 50 Hz ~ 60 Hz

- Light source: UV LED

- Curing modes: spot curing, signal-triggered curing, continuous curing

- Cooling system: air cooling or water cooling

- Control interface: touch screen

(Specifications may vary depending on configuration)

6. Important Safety and Operating Considerations

To ensure safe operation and long service life of Spot UV Curing Equipment, the following precautions should be observed:

Ensure proper power supply

- Electrical outlets must have good contact

- Operating voltage must remain within 100 ~ 240 VAC

- Frequency must be 50 Hz ~ 60 Hz

Effective grounding

- Both the controller and UV light source must be properly grounded

- This prevents hazards caused by static electricity

Temperature management

- Excessive temperature can damage components

- For air-cooled systems, ensure unobstructed air intake and exhaust

- For water-cooled systems, maintain stable and continuous water circulation

Condensation awareness

- When water temperature is lower than ambient temperature under high humidity, condensation may form

- Adjust water temperature or insulate water lines and light source surfaces accordingly

UV radiation protection

- UV radiation is harmful to the human body

- Operators should wear protective glasses, protective clothing, and appropriate safety equipment

Electromagnetic interference prevention

- Use shielded signal cables

- Route signal cables separately from high-voltage and power cables to prevent malfunctions

7. Conclusion

As manufacturing processes continue to advance toward higher precision and automation, CYD8 Spot UV Curing Equipment provides a reliable solution for controlled, efficient, and repeatable UV adhesive curing. With its touch-screen interface, precise curing control, and strong automation compatibility, this system helps manufacturers improve product quality while optimizing long-term operating costs.

For production environments that demand stability, accuracy, and scalability, Spot UV Curing Equipment is an essential component of modern UV curing technology.

CYD8 Spot UV Curing Equipment

CYD8 Spot UV Curing Equipment delivers precise UV adhesive curing with touch control, automation compatibility, and stable performance for modern production lines.

Product SKU: COUSZCYD-Y8E

Product Brand: COUSZ

Product Currency: VND

Product Price: 6888

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Works exactly as described.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com