CVX60 LED UV Curing System – An Optimized Line UV Curing Solution for Modern Manufacturing

As industrial manufacturing increasingly demands high precision, stable operation, and energy efficiency, UV LED curing technology is becoming the preferred alternative to conventional curing systems. In particular, line-type UV curing systems are being widely adopted across electronics, printing, precision components, and polymer material industries.

Among these solutions, the CVX60 LED UV Curing System stands out as a purpose-built device designed to meet the need for linear UV curing with high accuracy, flexible integration, and stable performance on automated production lines.

1. Overview of the CVX60 LED UV Curing System

The CVX60 LED UV Curing System is an industrial UV LED curing solution belonging to the line-type UV curing category. Instead of irradiating a wide surface or focusing on a single spot, the CVX60 concentrates UV energy into a narrow, linear irradiation area, enabling precise control over the curing zone.

The system is designed for applications such as:

- Linear UV adhesive curing

- UV ink curing along narrow traces

- Linear UV coating curing on conveyor systems

- Applications in camera modules, electronic components, and technical labels

Thanks to its automation-oriented design, the CVX60 LED UV Curing System can be easily integrated into robots, conveyors, or smart manufacturing systems, meeting the demands of modern factories.

2. Structure and Components of the CVX60 LED UV Curing System

One of the key strengths of the CVX60 LED UV Curing Machine lies in its well-designed modular structure, which ensures stable operation, easy maintenance, and flexibility for system expansion.

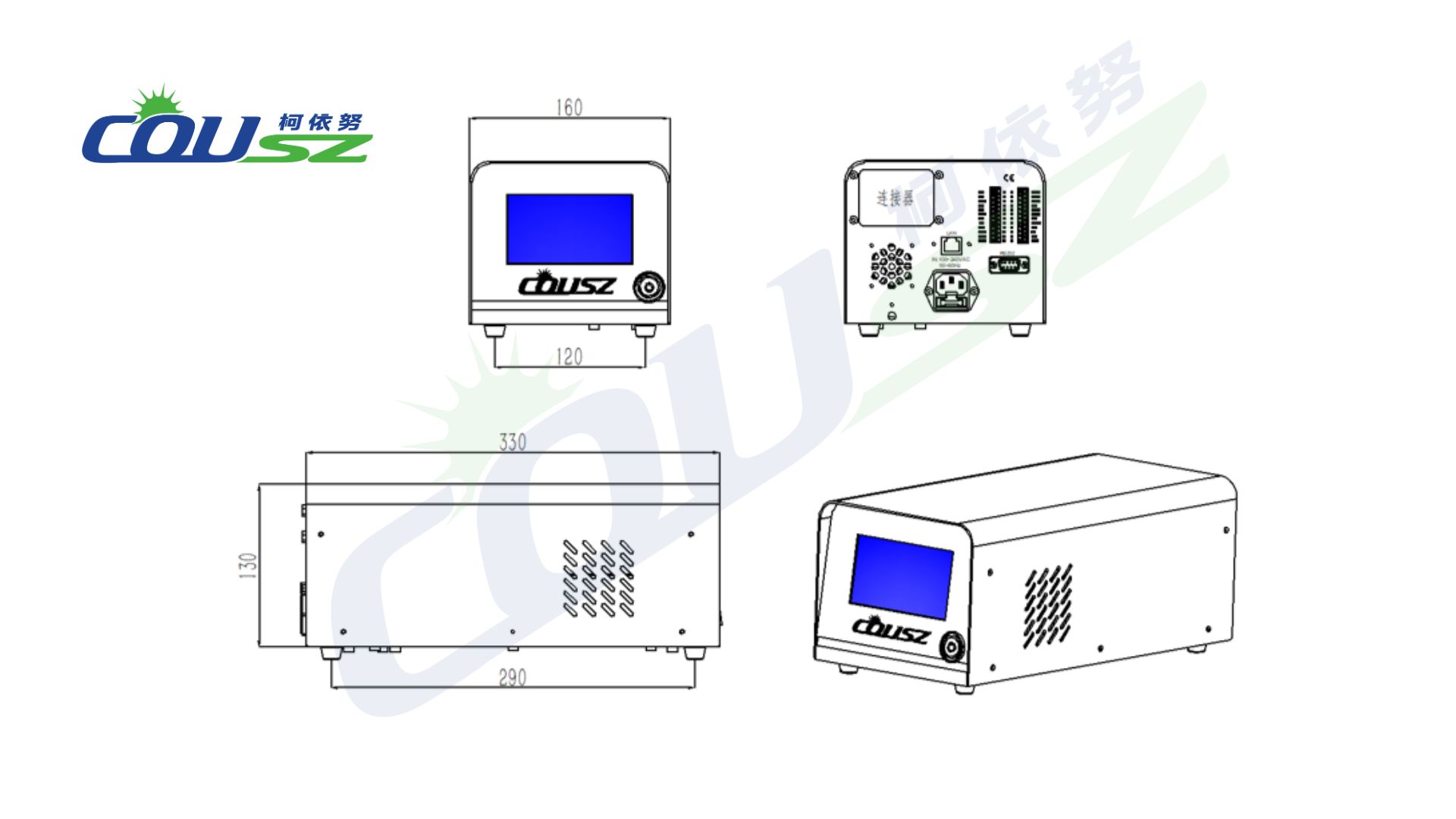

2.1. Controller

The UV LED controller of the CVX60 is specifically designed for linear curing, featuring a narrow irradiation area with uniform energy distribution. This design helps to:

- Improve curing efficiency for UV adhesives and inks

- Prevent UV exposure beyond the required curing area

- Reduce energy consumption compared to flood curing systems

Thanks to its focused irradiation characteristics, the CVX60 LED UV Curing System is particularly suitable for products requiring high precision.

| Item | Specification | Item | Specification |

|---|---|---|---|

| Dimensions (mm) | L330 × W160 × H130 mm | Power | 50W |

| Cooling | Fan cooling | Power Input | 100–240V AC 50~60Hz |

| Weight / Material | Approx. 3.5 kg, metal | Output Power | 10%–100% |

| Setting Lock | Built-in password for advanced settings | Display & Settings | Touch screen; time and intensity |

| Number of LED Heads | 1–4 pcs | Control Method | Foot pedal, SCM, PLC, RS232/RS485/TCP |

| Alarm | Over-temperature and fault alarms | Operating Time | Accumulated operating time record |

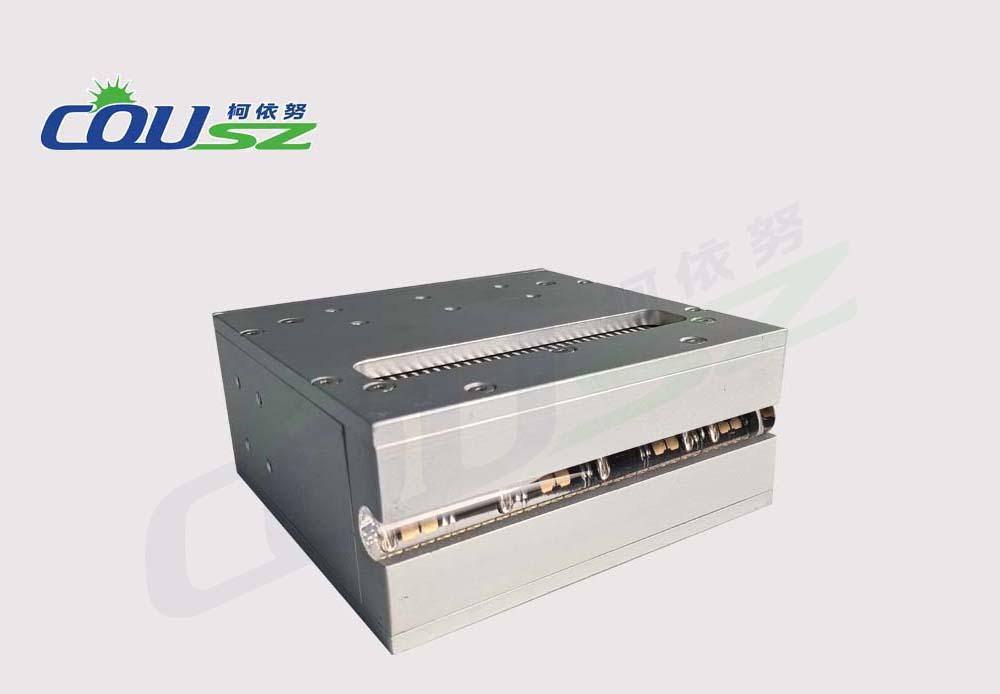

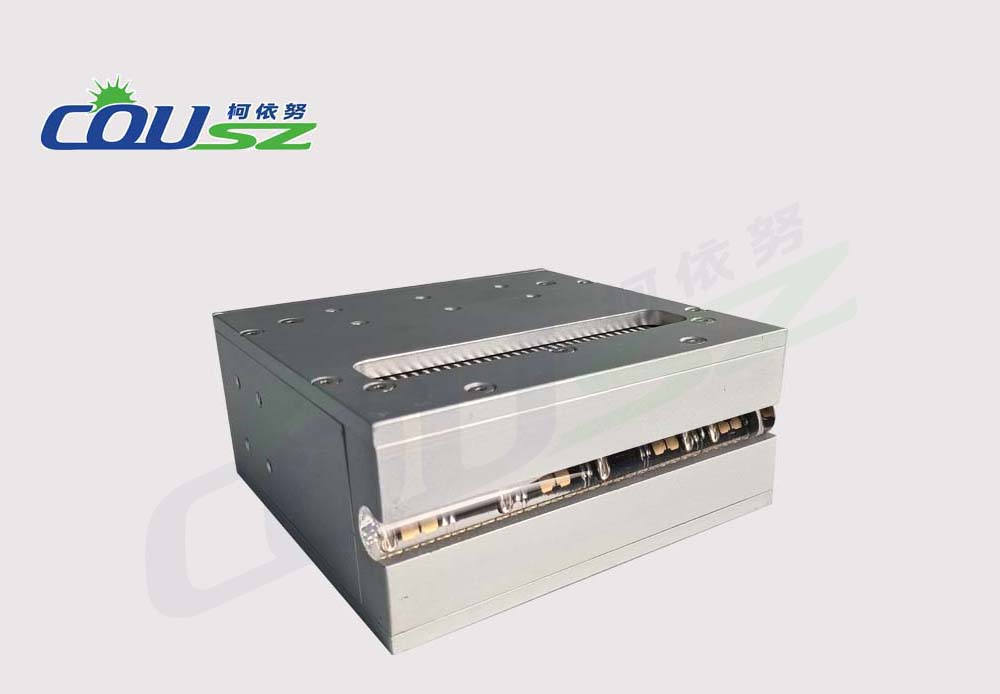

2.2. High-Performance UV LED Light Source

The UV LED system of the CVX60 uses high-quality LED chips, providing stable intensity and long service life. Compared with traditional mercury lamps, UV LED technology offers several advantages:

- Instant on/off with no warm-up time

- Stable output throughout operation

- Reduced maintenance and replacement costs

| Item | Specification | Item | Specification |

|---|---|---|---|

| Irradiation Area (mm) | 10 × 60 mm | Applications | Ink curing (especially inkjet), adhesive curing (CCM, VCM), inspection, etc. |

| Cooling | Fan cooling | LED Lifetime | >20,000 hours |

| Weight / Material | Approx. 3 kg, metal/aluminum | Wavelength (nm) | 365 / 385 / 395 / 405 |

| Intensity (mW/cm²) | Adjustable | Monitoring | Intensity, temperature, etc. |

| Connection Cable | 2–5 m (customizable) |

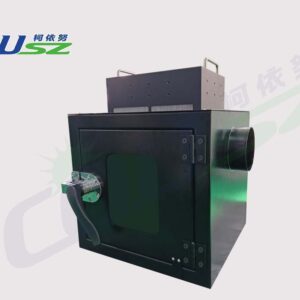

2.3. Efficient Cooling System

The CVX60 is equipped with an optimized cooling system that effectively controls temperature during continuous operation. Maintaining stable temperature provides several benefits:

- Protection of UV LED chips

- Reduced thermal impact on heat-sensitive materials

- Stable performance during long production shifts

2.4. Intelligent Control Unit

The controller allows users to adjust:

- UV output power

- Irradiation time

- Operating modes and PLC communication

This enables the CVX60 LED UV Cure System to synchronize easily with automated production lines and adapt to various manufacturing scenarios.

3. Comparison Between the CVX60 LED UV Curing System and Spot UV Curing Machines

To select the right curing solution, manufacturers need to understand the differences between line-type UV curing systems like the CVX60 and spot UV curing machines.

3.1. Irradiation Area

- CVX60 LED UV Curing System: Linear irradiation, ideal for curing adhesives or inks along continuous lines

- Spot UV curing machines: Focused irradiation at a single point, suitable for isolated curing spots

For products with long adhesive lines or continuous ink traces, the CVX60 offers clear advantages.

3.2. Production Line Efficiency

Spot UV curing machines are typically suited for manual or semi-automatic processes. In contrast, the CVX60 LED UV Curing System is designed for high-speed production lines, helping to:

- Reduce cycle time

- Increase overall productivity

- Ensure consistent curing quality across products

3.3. Operating Cost

With UV LED technology and an optimized irradiation area, the CVX60 helps reduce power consumption and maintenance costs compared to using multiple spot curing heads for the same application.

Consultation for the CVX60 LED UV Curing System

Are you looking for a CVX60 LED UV Curing System that fits your production line?

👉 Contact COUSZ Vietnam today for in-depth technical consultation:

-

Contact person: Ms. Yuna

-

Hotline: +84 965 535 348

-

Email: sales03@cousz.com

CVX60 LED UV Curing system

The CVX60 LED UV Curing system offers smart interface, stable power, and 4 cooling modes for flexible curing in diverse production environments.

Product SKU: COUSZCVX60E

Product Brand: COUSZ

Product Currency: VND

Product Price: 6668

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Better than expected.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com