CVX120 UV Light Curing Lamp – An Optimal UV LED Curing Solution for Manufacturing

As factories increasingly accelerate automation, streamline production processes, and optimize operating costs, UV LED curing technology is playing a critical role across many industrial sectors. Beyond shortening production cycles, modern UV curing systems also deliver high precision, superior energy control, and improved environmental performance.

Among the new-generation linear UV curing solutions, the CVX120 UV Light Curing Lamp has been developed to meet stringent requirements for performance, stability, and seamless integration into industrial production lines.

1. What is the CVX120 UV Light Curing Lamp? How does it work?

The CVX120 UV Light Curing Lamp is an industrial UV LED curing system belonging to the line UV curing system category. Unlike conventional UV curing chambers or wide-area UV lamps, the CVX120 concentrates UV energy into a narrow yet extended linear irradiation zone, enabling precise curing along adhesive lines, ink traces, or coating edges.

The operating principle of the CVX120 UV Light Curing Lamp is based on photopolymerization. When UV LED light at suitable wavelengths is applied to UV-sensitive materials such as adhesives, inks, or coatings, photoinitiators absorb the energy and trigger polymer cross-linking reactions.

This process occurs through the following steps:

- UV LEDs emit light at specific wavelength ranges

- UV energy activates the curing reaction within the material

- The material transitions from a liquid to a solid state in a very short time

- The cured surface achieves stable mechanical and chemical properties

Thanks to precise control of irradiation intensity and exposure time, the CVX120 effectively minimizes under-curing or over-curing issues.

2. Structure of the CVX120 UV Light Curing Lamp

One of the key differentiators of the CVX120 UV Light Curing Lamp is its scientifically designed modular structure, ensuring stable operation, easy maintenance, and flexible system expansion.

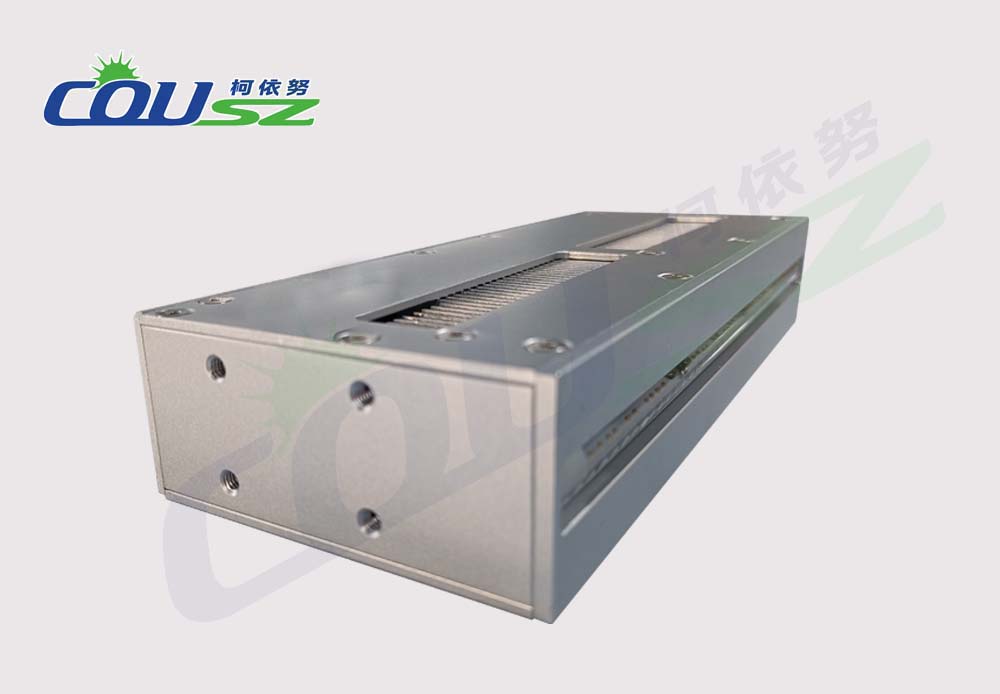

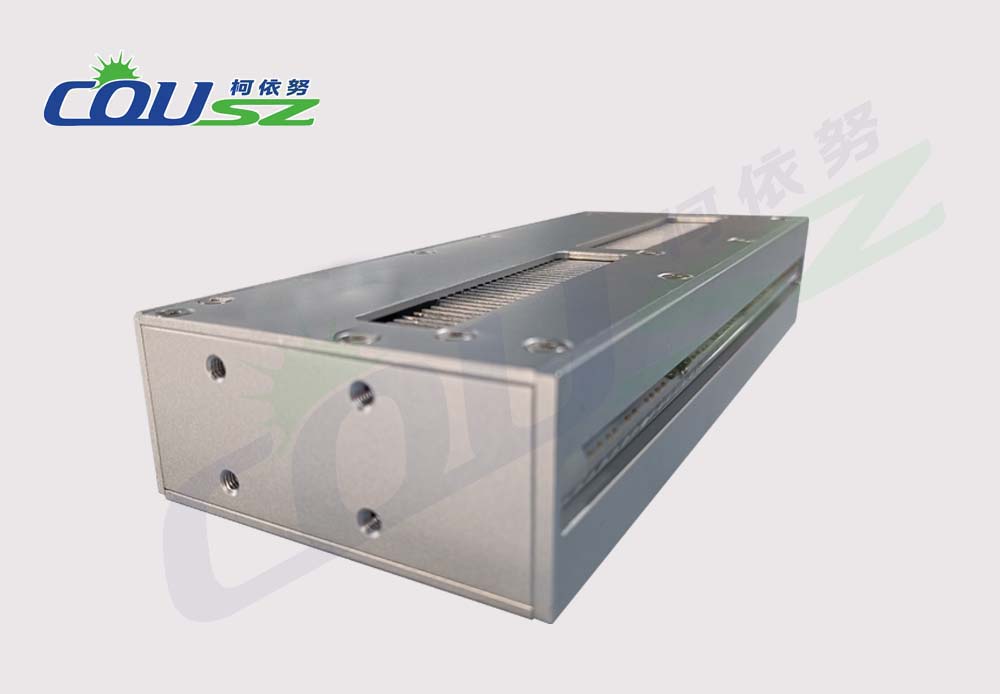

2.1. Linear UV LED Irradiation Head

The UV LED irradiation head of the CVX120 is specifically engineered for linear curing applications, featuring a narrow irradiation width with uniform UV energy distribution. This design provides several advantages:

- Improved curing efficiency for UV adhesives and inks

- Prevention of unwanted irradiation beyond the target area

- Reduced energy loss compared to wide-area curing

LIGHT SOURCE

| Item | Specification | Item | Specification |

|---|---|---|---|

| Light-emitting surface area (mm) | 10 × 120 mm | Applications | Ink curing (especially inkjet), adhesive curing (CCM, VCM), inspection, etc. |

| Cooling | Fan | LED light source lifetime | > 20,000 hours |

| Weight / Material | Approx. 3 kg / Metal / Aluminum | Wavelength (nm) | 365 / 385 / 395 / 405 |

| Intensity (mW/cm²) | Adjustable | Monitoring | Intensity, temperature, etc. |

| Connection cable | 2–5 m (customizable) |

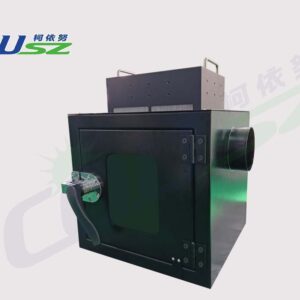

2.2. Cooling System

The CVX120 UV Light Curing Lamp is equipped with an efficient cooling system (air or water cooling depending on configuration), ensuring stable temperature control during continuous operation. This is especially critical for:

- Heat-sensitive materials

- Long-duration production shifts

- Applications requiring high process stability

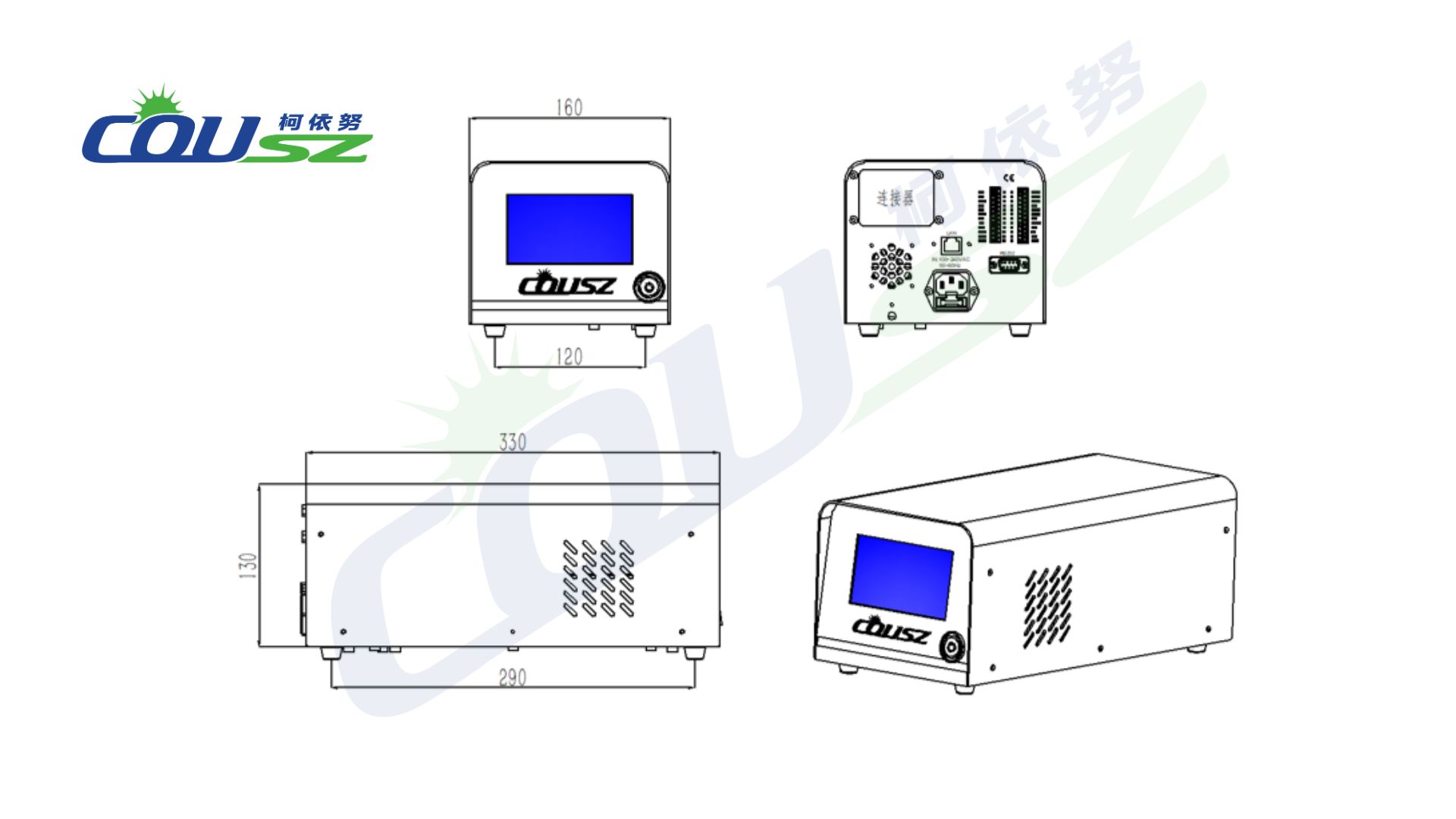

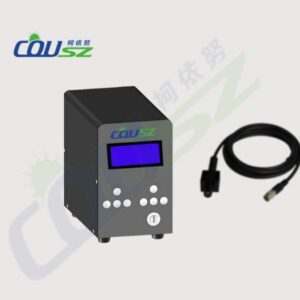

2.3. Intelligent Controller

The controller allows users to:

- Adjust UV output power

- Set curing time parameters

- Connect to PLCs, robots, or automation systems

As a result, the CVX120 can be easily integrated into modern automated production lines.

| Item | Specification | Item | Specification |

|---|---|---|---|

| Dimensions (mm) | L330 × W160 × H130 mm | Power | 50 W |

| Cooling | Fan cooling | Input power | 100–240V AC, 50–60 Hz |

| Weight / Material | Approx. 3.5 kg / Metal | Output power | 10%–100% |

| Setting lock | Password-protected advanced settings | Display & settings | Touchscreen; time, intensity |

| Number of LED light sources | 1–4 units | Control | Foot switch, SCM, PLC, RS232 / RS485 / TCP |

| Alarm | Over-temperature and system fault alarms | Operating time | Accumulated operating time recording |

3. Comparison between the CVX120 UV Light Curing Lamp and Traditional Mercury UV Lamps

The transition from mercury UV lamps to UV LED technology has become an inevitable trend in industrial manufacturing. Key differences include:

3.1. Curing Efficiency

- CVX120 (UV LED): Concentrated energy, fast curing, uniform linear irradiation

- Mercury UV lamps: Wide-area irradiation with significant energy loss

3.2. Response Time

- CVX120: Instant on/off, ready for operation immediately

- Mercury UV lamps: Require warm-up time, causing production interruptions

3.3. Energy Consumption

- CVX120: Significantly reduced power consumption

- Mercury UV lamps: High energy consumption and lower conversion efficiency

3.4. Maintenance and Environmental Impact

- CVX120: Mercury-free, environmentally friendly, low maintenance

- Mercury UV lamps: Require periodic lamp replacement and complex waste handling

4. Why Choose the CVX120 UV Light Curing Lamp from COUSZ?

There are many reasons why the CVX120 UV Light Curing Lamp is a reliable choice for manufacturers:

- Optimized design for automated and semi-automated production

- High curing efficiency with precise irradiation control

- Reduced long-term operating costs

- Flexible customization for specific application requirements

- Developed and supported by COUSZ’s experienced UV LED technical team

COUSZ delivers not only equipment, but also comprehensive UV curing solutions for industrial customers.

Contact for CVX120 UV Light Curing Lamp Consultation

Are you looking for a CVX120 UV Light Curing Lamp suitable for your production line?

👉 Contact COUSZ Vietnam for professional technical consultation:

-

Contact person: Ms. Yuna

-

Hotline: +84 965 535 348

-

Email: sales03@cousz.com

CVX120 UV Light Curing Lamp

CVX120 UV Light Curing Lamp: flexible auto/manual curing, multiple heat dissipation options, compact & durable design.

Product SKU: COUSZCVX120E

Product Brand: COUSZ

Product Currency: VND

Product Price: 6668

Price Valid Until: 2025-12-31

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Outstanding performance.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com