CVX100 UV Light Curing Machine – An Optimal UV Curing Solution for Modern Manufacturing

In the context of industrial manufacturing shifting rapidly toward automation and energy optimization, UV LED curing solutions are increasingly becoming the preferred choice for manufacturers. In particular, curing systems that offer precise irradiation control, reduced power consumption, and stable operation on continuous production lines are setting new industry standards.

Within this category, the CVX100 UV Light Curing Machine is recognized as an efficient linear UV curing solution, suitable for a wide range of industrial applications.

1. Overview of the CVX100 UV Light Curing Machine

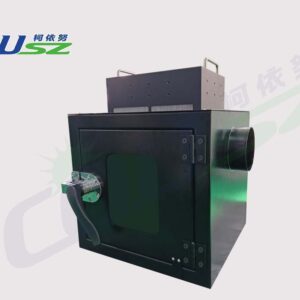

The CVX100 UV Light Curing Machine is an industrial UV LED curing system belonging to the line-type UV curing category. Instead of irradiating the entire product surface like traditional UV curing chambers, the CVX100 concentrates UV energy into a narrow, linear irradiation area, enabling fast, precise, and uniform curing.

Thanks to its automation-friendly design, the CVX100 UV Curing Machine can be easily integrated into high-speed production lines, robotic systems, and smart manufacturing environments.

2. Structure of the CVX100 UV Light Curing Machine

One of the key strengths of the CVX100 UV Light Curing Machine lies in its scientifically designed modular structure, which ensures high performance while simplifying maintenance and future expansion.

Light Source Specifications

The irradiation head of the CVX100 is specifically engineered for linear curing, featuring a narrow irradiation area with uniform UV intensity distribution. This design delivers several advantages:

- Enhanced curing efficiency for UV adhesives and inks

- Prevention of unnecessary UV exposure outside the target area

- Reduced energy loss compared to area-wide UV curing

| Item | Specification | Item | Specification |

|---|---|---|---|

| Light-emitting surface area (mm) | 10 × 100 mm | Applications | Ink curing (especially inkjet printing), adhesive curing (CCM, VCM), inspection, etc. |

| Cooling | Fan cooling | LED light source lifetime | > 20,000 hours |

| Weight / Material | Approx. 3 kg / Metal (Aluminum) | Wavelength (nm) | 365 / 385 / 395 / 405 |

| Intensity (mW/cm²) | Adjustable | Monitoring | Intensity, temperature, etc. |

| Connection cable | 2–5 m (customizable) |

Cooling System

The CVX100 is equipped with an efficient cooling system (air or water cooling depending on configuration), ensuring stable temperature control during continuous operation. This feature is especially critical for applications requiring strict thermal management.

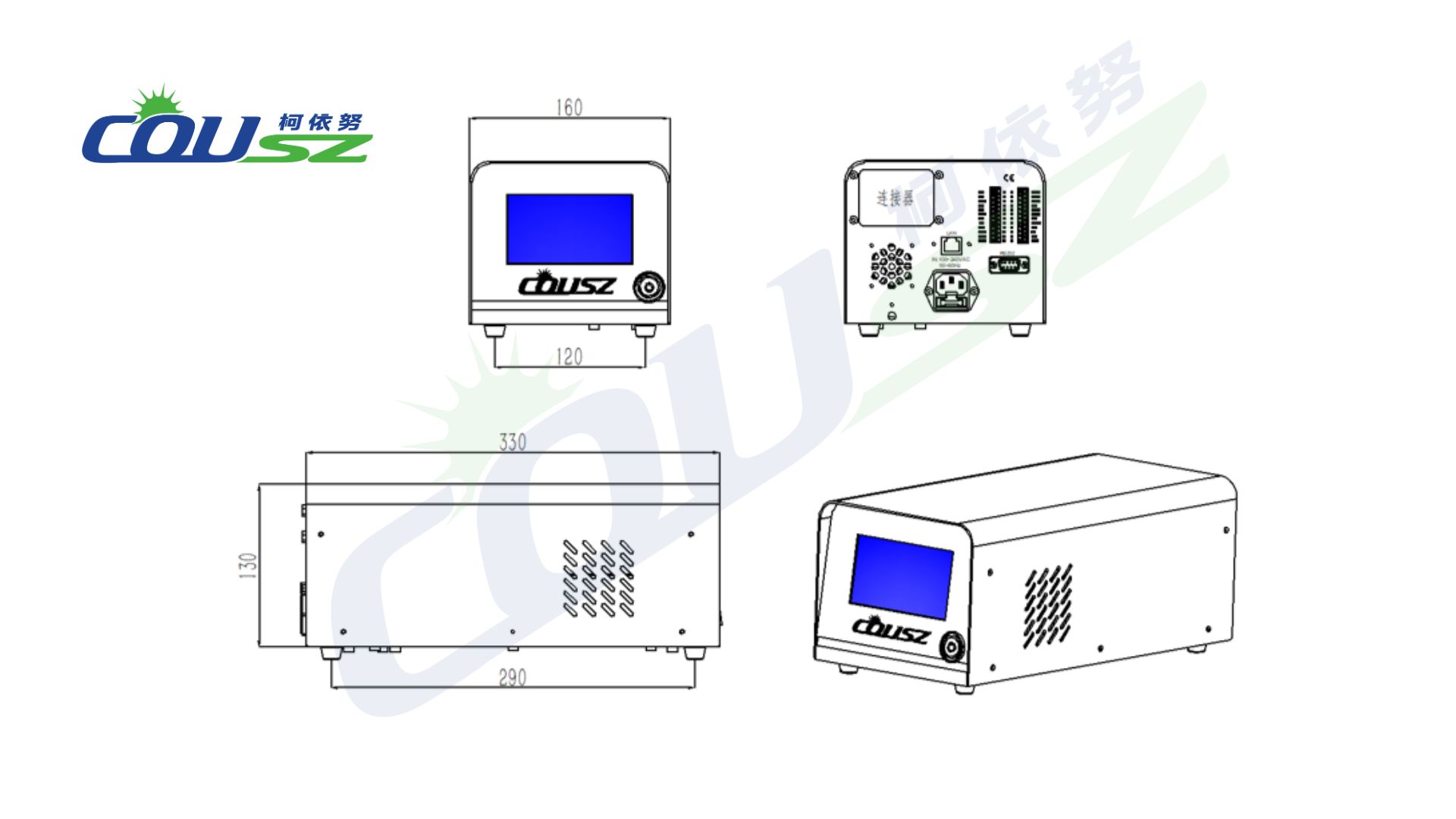

Central Controller

The control unit allows flexible adjustment of irradiation power, curing time, and operating modes. In addition, PLC connectivity is supported, enabling seamless synchronization of the CVX100 UV Light Curing Machine with automated production lines.

| Item | Specification | Item | Specification |

|---|---|---|---|

| Dimensions (mm) | L330 × W160 × H130 | Power | 50 W |

| Cooling | Fan cooling | Input power | 100–240 V AC, 50–60 Hz |

| Weight / Material | Approx. 3.5 kg / Metal | Output power | 10%–100% |

| Setting lock | Password-protected advanced settings | Display & settings | Touch screen; time, intensity |

| Number of LED light sources | 1–4 units | Control | Foot pedal, SCM, PLC, RS232 / RS485 / TCP |

| Alarm | Over-temperature and system fault alerts | Operating time | Accumulated usage time recording |

3. Operating Principle of the CVX100 UV Light Curing Machine

The CVX100 UV Light Curing Machine operates based on the principle of photopolymerization. When UV light irradiates UV adhesives, inks, or coatings, photoinitiators absorb the UV energy and trigger polymer cross-linking reactions.

The basic process includes:

- UV LEDs emit light at appropriate wavelengths

- UV energy activates photoinitiators within the material

- The material transitions rapidly from liquid to solid

- The surface achieves the required mechanical and chemical strength

By precisely controlling irradiation intensity and exposure time, the CVX100 UV Light Curing Machine effectively minimizes under-curing and over-curing issues.

4. Comparison Between the CVX100 UV Light Curing Machine and Traditional UV Curing Chambers

To select the right equipment, manufacturers should clearly understand the differences between the CVX100 UV Light Curing Machine and conventional UV curing chambers.

Coverage and Precision

- CVX100: Linear curing with precise control of the target area

- Traditional UV chamber: Wide-area irradiation with limited control

Efficiency and Energy Consumption

- CVX100: Concentrated energy, high efficiency, and lower power consumption

- Traditional UV chamber: Higher energy consumption, lower efficiency for small products

Integration Capability

- CVX100: Easily integrated into automated production lines

- Traditional UV chamber: More suitable for manual or semi-automated processes

Operating Cost

- CVX100: Low maintenance cost and long LED lifespan

- Traditional UV chamber: Frequent lamp replacement and higher maintenance costs

Overall, the CVX100 UV Light Curing Machine is an optimal choice for factories pursuing lean manufacturing and advanced automation.

Contact for CVX100 UV Light Curing Machine Consultation

Are you looking for a CVX100 UV Light Curing Machine that fits seamlessly into your production line?

👉 Contact COUSZ today for professional technical consultation:

-

Contact person: Ms. Yuna

-

Hotline: +84 965 535 348

-

Email: sales03@cousz.com

The CVX100 UV Light Curing Machine

The CVX100 UV Light Curing Machine ensures safety with intelligent overheat alerts, features a compact design for easy line integration.

Product SKU: COUSZCVX100E

Product Brand: COUSZ

Product Currency: VND

Product Price: 6668

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Great attention to detail.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com