COUSZ 405nm UV Spot Curing Machine

Precision Curing Solution for Small and Delicate Components

1. Overview of the 405nm UV Spot Curing Machine

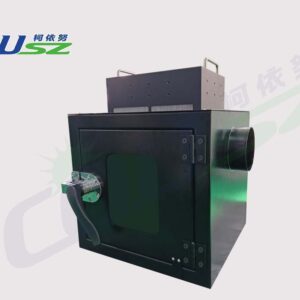

The 405nm UV Spot Curing Machine is a point-type UV curing system specifically designed for applications requiring high precision and a small irradiation area. Unlike conventional flood UV curing systems, the UV Spot curing system concentrates UV energy onto a single point or a very limited area, enabling precise, efficient, and stable curing control.

With a 405nm wavelength, this machine is particularly suitable for UV adhesives, UV inks, and thin coatings commonly used in electronics, precision components, engineering plastics, and small-sized products. The 405nm UV Spot Curing Machine not only significantly shortens curing time but also minimizes the risk of product deformation caused by heat.

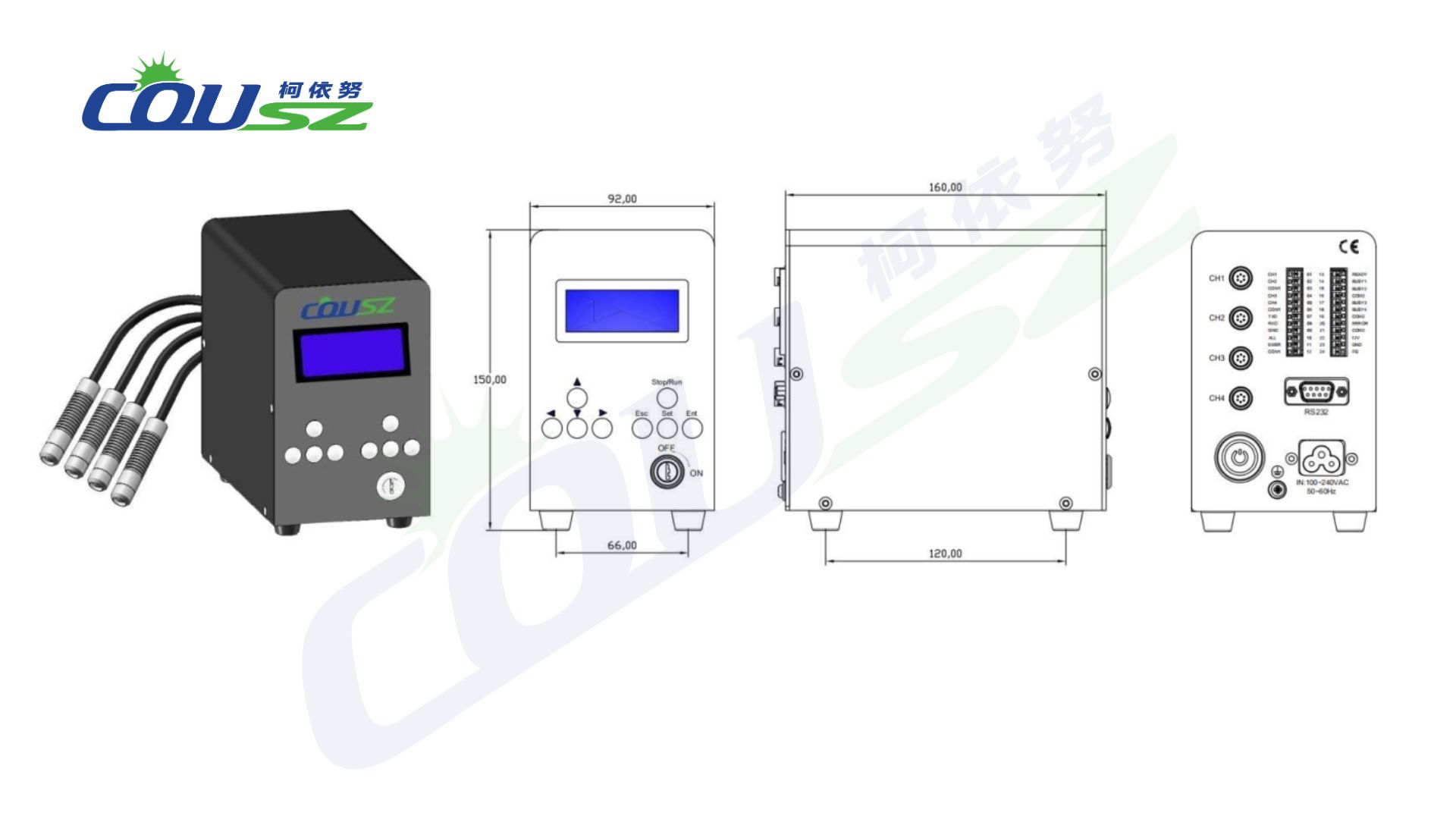

2. Structure of the UV Spot Curing Machine

A standard 405nm LED UV Spot Cure Machine system typically consists of two core components: the UV LED spot lamp head and the central controller. The close integration of these two components determines the overall performance and operational stability of the system.

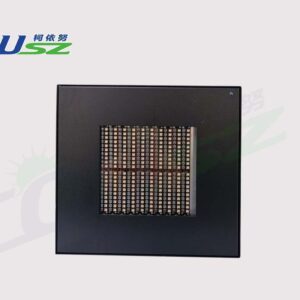

2.1 405nm UV LED Spot Lamp Head

The lamp head is the component that directly emits UV light to perform the curing process. For UV Spot curing machines, the lamp head is usually compact in design, easy to install, and capable of focusing UV light onto a very small area.

Key features of the 405nm UV LED spot lamp head include:

- Stable UV output at a 405nm wavelength

- Compact size for easy integration into confined spaces

- Adjustable irradiation angle and working distance

- Low heat generation, suitable for heat-sensitive materials

Thanks to this design, the LED UV Spot Cure machine can accurately cure individual adhesive points and small bonding areas without affecting surrounding regions.

2.2 UV Spot Curing Machine Controller

The controller serves as the “brain” of the LED UV Spot curing machine. It allows operators to set and manage curing parameters such as irradiation time, output power, and light intensity.

Key features of the controller include:

- Multilingual interface: supports multiple languages, easy to understand, ideal for international production environments

- Simple operation: intuitive controls enable fast operation and reduce training time

- Flexible LED control: supports independent control of 4-channel or 8-channel LED outputs, allowing separate adjustment of power, irradiation time, and intensity for each channel

With this flexible control capability, the UV LED Spot curing system can meet diverse curing requirements within the same production line.

3. Applications of the 405nm UV Spot Curing Machine

The 405nm UV Spot Cure equipment is widely used in industries that demand high precision, especially for products with small dimensions or complex structures.

Typical applications include:

- UV adhesive curing for electronic components and PCB assemblies

- UV bonding of camera modules, sensors, and chips

- UV ink curing for fine-detail printing

- Temporary fixation of components during assembly

- Curing of thin coatings on engineering plastics or small metal parts

Thanks to its fast and precise curing performance, the UV Spot curing system helps increase productivity, reduce defects, and improve overall product quality.

4. Comparison Between UV Spot Curing and Traditional Thermal Curing

For many years, thermal curing has been a common method for drying adhesives and coatings. However, when compared to the UV Spot Cure machine, thermal curing shows several limitations.

Curing Time

- UV Spot Cure machine: curing time measured in seconds

- Thermal curing: requires several minutes to tens of minutes

This enables the UV Spot Cure machine to significantly optimize production speed.

Energy Efficiency

- UV Spot Cure machine: uses LED technology with low power consumption

- Thermal curing: consumes high energy due to prolonged high-temperature operation

No Product Deformation

A key advantage of the UV Spot Cure machine is:

- Low heat generation

- No warping or deformation of heat-sensitive materials such as plastics, thin films, and electronic components

In contrast, thermal curing can easily cause cracking, shrinkage, or reduced product lifespan.

5. Key Advantages of the 405nm UV Spot Cure Machine

In summary, the 405nm UV Spot Curing Machine offers outstanding benefits:

- Fast and highly precise point curing

- Energy-saving operation with low running costs

- Protection of heat-sensitive materials

- Easy operation with a multilingual user interface

- Flexible LED control with 4-channel or 8-channel configurations

- Easy integration into automated production lines

These advantages make the UV Spot curing machine an optimal choice for modern manufacturing facilities.

Conclusion

As manufacturing increasingly demands higher precision and efficiency, the 405nm UV Spot Curing Machine stands out as an effective point-curing solution and a superior alternative to traditional thermal curing. With its compact design, flexible control capabilities, and excellent curing performance, the UV Spot curing machine not only enhances product quality but also helps businesses reduce costs and strengthen their competitive advantage.

Contact Ms Yuna for technical support!

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com

CVD405 Spot Curing Machine

The 405nm UV Spot Curing Machine offers fast, energy-saving, and heat-free curing for small and precise components in industrial production.

Product SKU: COUSZCVD405E

Product Brand: COUSZ

Product Currency: VND

Product Price: 6888

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

Emily –

Excellent service from Cousz.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com