Cooling System for UV Curing – An Essential Solution for Industrial UV Systems

In industrial UV curing systems, the heat generated during operation directly affects performance, stability, and equipment lifespan. The Cooling system for UV Curing plays a critical role in temperature control, UV lamp protection, and ensuring a continuous, safe, and efficient curing process.

1. What Is a Cooling System for UV Curing?

A Cooling system for UV Curing is a specialized system or component integrated into UV curing machines to reduce and dissipate heat generated by UV lamps, UV LED light sources, and electronic components.

In continuous production environments, poor temperature control can cause rapid power degradation of UV lamps, material deformation, or even safety risks for operators. Therefore, the cooling system is not merely an accessory but a mandatory component of modern UV curing systems.

2. Functions of the Cooling System for UV Curing

-

Stabilizing operating temperature

The cooling system maintains an optimal temperature for UV lamps and electrical components, preventing overheating during prolonged operation. -

Extending UV lamp lifespan

High temperature is a primary factor that shortens the lifespan of UV lamps and UV LEDs. An effective Cooling system for UV Cure helps reduce replacement and maintenance costs. -

Ensuring curing quality

Stable temperature conditions enable uniform curing of UV adhesives, inks, and coatings, minimizing defects and improving product yield. -

Enhancing production safety

A reliable cooling system reduces the risk of fire, equipment failure, and operational hazards in high-intensity industrial environments.

3. Common Types of Cooling Systems for UV Curing

Depending on machine power, UV technology, and operating conditions, Cooling systems for UV Cure are designed in various configurations.

Fan-Based Cooling System

This is the most common type, using fans to blow and dissipate heat into the surrounding environment.

Advantages:

-

Cost-effective

-

Easy to install and maintain

-

Suitable for small to medium-power UV curing machines

Water Cooling System

This system uses circulating water or coolant to absorb and remove heat from the UV curing equipment.

Advantages:

-

High cooling efficiency

-

Stable performance for high-power UV curing systems

-

Ideal for 24/7 continuous production lines

Natural Cooling System

This method utilizes heat sink fins and natural air convection to dissipate heat.

Advantages:

-

No power consumption

-

Minimal maintenance

-

Commonly used for low-power UV LED systems

Air Cooling (Compressed Air Cooling)

Compressed air or guided airflow is used to cool heat-generating areas directly.

Advantages:

-

Fast cooling response

-

Suitable for specialized applications and confined spaces

4. Why Is It Important to Choose the Right Cooling System for UV Curing?

Each UV system has unique requirements in terms of power, wavelength, operating time, and production environment. Selecting the appropriate Cooling system for UV Curing helps businesses:

-

Optimize equipment investment efficiency

-

Reduce the risk of unplanned downtime

-

Improve durability and overall system stability

Consultation for Cooling System for UV Curing Selection

Are you looking for a Cooling system for UV Cure that fits your production line?

Don’t let temperature issues compromise equipment performance and service life.

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com

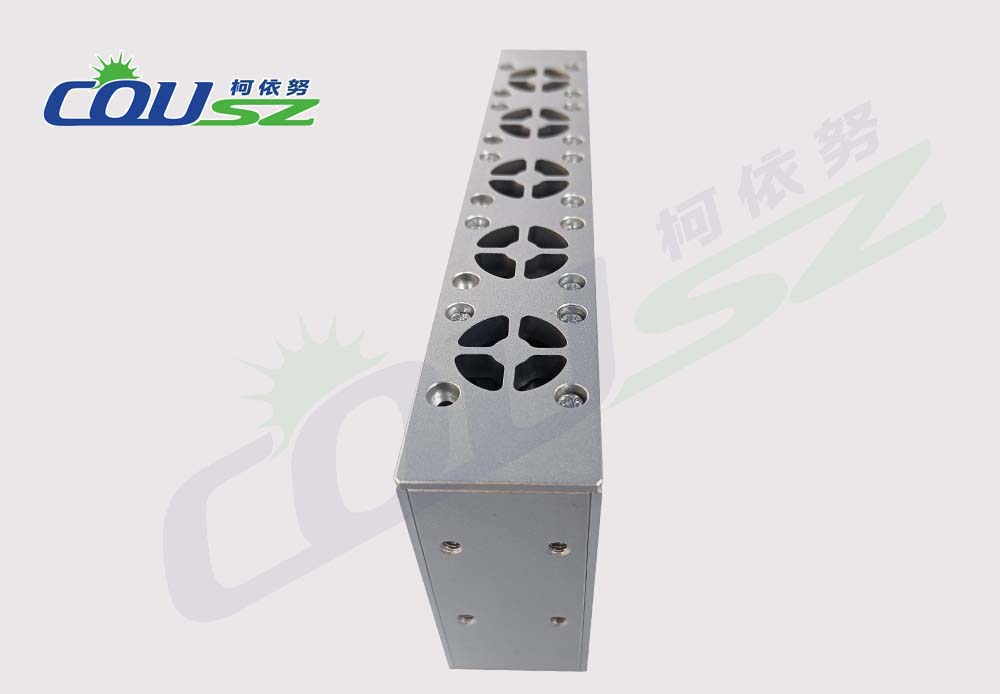

Cooling system for UV Curing

Cooling system for UV Curing helps control temperature, protect UV lamps, and ensure stable, safe, and efficient industrial UV curing processes.

Product SKU: COOLING01E

Product Brand: COUSZ

Product Currency: VND

Product Price: 2222

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com

Brian –

Very professional service.