405nm UV LED Curing Conveyor – UV Curing Solution for Modern Production Lines

The 405nm UV LED Curing Conveyor is increasingly becoming the preferred choice for modern manufacturing plants where high speed, process stability, and automation capability are critical. Instead of fragmented curing steps or heavy reliance on manual operations, this integrated solution enables continuous UV curing synchronized with production line workflows, helping manufacturers maximize productivity while maintaining consistent quality control.

1. Introduction to the 405nm UV LED Curing Conveyor

As industrial manufacturing continues to move toward standardization and automation, the 405nm UV LED Curing Conveyor has been developed as a comprehensive solution for curing UV adhesives, inks, and coatings. Products are placed on the conveyor and move continuously through the UV irradiation zone, allowing the curing process to occur in a stable, repeatable, and highly controlled manner.

Compared to conventional UV curing methods, an integrated conveyor system significantly reduces waiting time, minimizes product-to-product variation, and allows for easy capacity expansion as production demand increases.

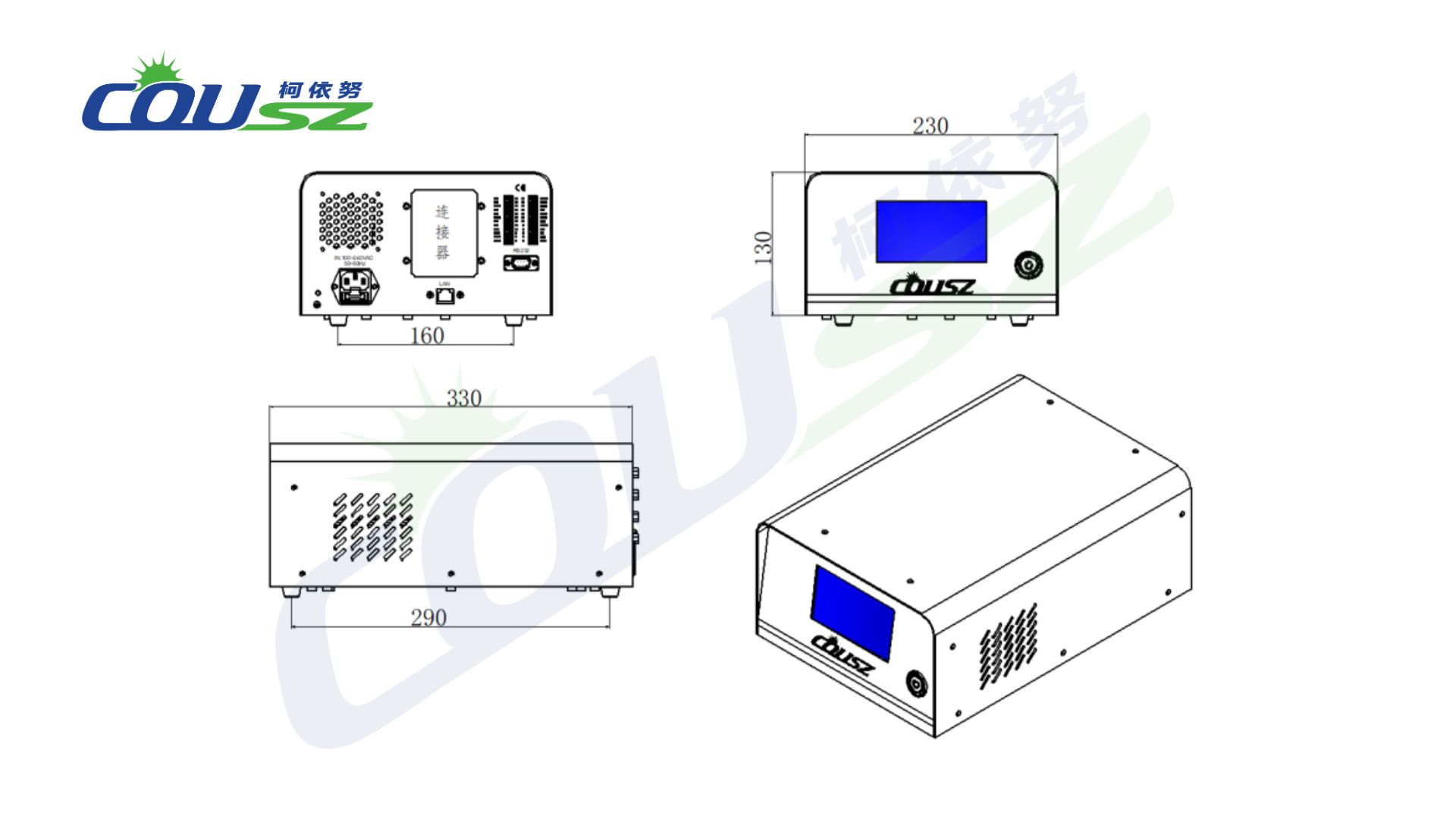

2. Structure of the 405nm UV LED Curing Conveyor

To meet long-term operational requirements in industrial environments, the 405nm UV LED Curing Conveyor is designed with a robust structure optimized for seamless production line integration:

-

Conveyor system:

Acts as the core component, ensuring smooth and stable product transportation through the curing zone. Conveyor speed can be flexibly adjusted to match different materials and curing requirements. -

UV light source (UV LED or conventional UV):

Provides the required energy for UV curing, enabling precise control of irradiation intensity and exposure time. -

Enclosed UV curing chamber:

Concentrates UV energy, minimizes energy loss, and prevents UV leakage into the surrounding environment, ensuring operator safety. -

Central control unit:

Allows configuration and monitoring of operating parameters such as conveyor speed, curing time, and UV intensity. The system can be easily connected to the factory’s centralized control architecture.

3. Key Features of the 405nm UV LED Curing Conveyor

Thanks to its integrated design and modern manufacturing orientation, the 405nm UV LED Curing Conveyor offers several outstanding advantages:

-

Continuous UV curing:

Ideal for mass production without interrupting production flow. -

Uniform curing quality:

Reduces variation between products, which is especially critical in electronics and precision component manufacturing. -

Easy automation integration:

Compatible with semi-automatic and fully automated production lines. -

Operational safety:

Enclosed curing chamber design significantly reduces UV exposure risks. -

Scalability:

Light sources, conveyor length, and additional modules can be upgraded as production expands.

4. Comparison with Other UV Curing Solutions

| Criteria | UV Conveyor Curing System | Spot UV Curing Machine | UV Curing Oven |

|---|---|---|---|

| Operating method | Continuous conveyor-based | Point-by-point irradiation | Batch processing |

| Production speed | Very high, ideal for mass production | Medium to low | Medium |

| Curing uniformity | High, consistent across products | Operator-dependent | Medium |

| Automation capability | Easy PLC/MES integration, fully automated | Semi-automatic or manual | Limited automation |

| Scalability | Easy to upgrade conveyor and light heads | Limited to individual spots | Moderate |

| Exposure time control | Adjusted via conveyor speed | Manual operation required | Fixed per batch |

| Efficiency for large volumes | Highly efficient | Not optimal | Best for small–medium batches |

| Production line layout | Requires standardized layout and space | Minimal layout requirements | Requires dedicated area |

| Operational safety | Enclosed chamber, low UV exposure | Low without shielding | Enclosed, but often opened during loading/unloading |

| Application flexibility | High for various product types | Good for repair or small customization | Suitable for low-volume products |

| Cost efficiency at scale | Cost-effective long-term | Better for low-volume tasks | Moderate |

| MES / Smart Factory compatibility | Highly compatible | Difficult to integrate | Difficult to integrate |

5. Why Choose the 405nm UV LED Curing Conveyor?

-

Optimizes productivity and reduces overall production time

-

Enhances process stability and curing repeatability

-

Minimizes reliance on manual operations

-

Aligns with smart factory and sustainable manufacturing strategies

These advantages make the 405nm UV LED Curing Conveyor a long-term solution for manufacturers focused on efficiency, quality, and future-ready production systems.

Consultation for 405nm UV LED Curing Conveyor

Selecting the right 405nm UV LED Curing Conveyor depends on material type, UV curing requirements, and the automation level of each production line.

👉 For detailed consultation and customized system configuration, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

405nm UV LED Curing Conveyor

405nm UV LED curing conveyor system for automated production lines, delivering stable, continuous, and high-efficiency UV curing performance.

Product SKU: COUSZCVC10E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-27

Product In-Stock: InStock

4.99

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Smooth service from start to end.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com