Introduction to the H86 4-Head Spot Curing System: A precision UV curing solution for modern manufacturing

As industries such as electronics manufacturing, camera modules, and precision components continue to demand higher accuracy and faster production speeds, the Spot Curing System is increasingly replacing traditional thermal curing methods. Among these solutions, the H86 4-Channels Spot Curing System stands out thanks to its balanced design, combining performance, cost efficiency, and automation compatibility.

This article provides a clear overview of the system structure, operating principles, key advantages, a comparison with 8-head models, and practical guidance for selecting the right equipment for real production needs.

1. Overview of the H86 4-Head Spot Curing System

The H86 4-head Spot Curing System uses focused UV LED light directed at precise curing points, enabling fast and accurate curing of UV adhesives, UV inks, and thin coatings. Unlike flood-type UV curing machines, point curing technology concentrates energy only where needed, significantly reducing thermal impact on surrounding areas.

As products become smaller, more complex, and increasingly sensitive to heat, this UV point curing solution helps manufacturers improve product quality, reduce defects, and increase overall production efficiency.

2. Introduction to the H86 4-Head Spot Curing System

The H86 4-head Spot Curing System is designed specifically for small to medium-sized production lines that require simultaneous curing at multiple locations while maintaining reasonable investment costs.

Equipped with four independent UV LED lamp heads, the system allows multiple curing points to operate at the same time or to be grouped according to different process stages. This design provides high flexibility in line layout and meets the strict precision requirements of modern manufacturing applications.

3. Structure and Operating Principle

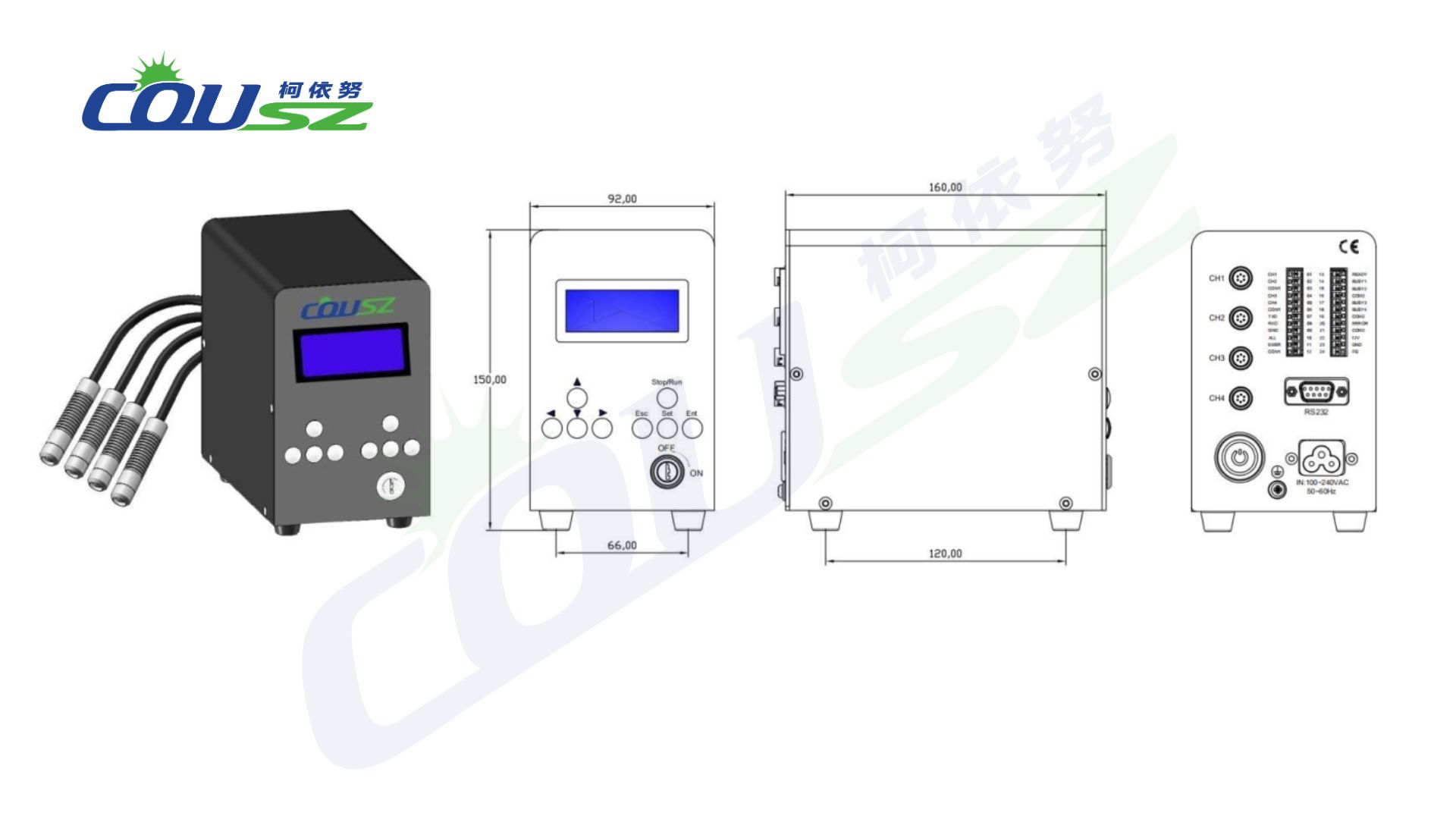

A standard H86 4-head Spot Curing System consists of two main components:

- Central control unit

- UV LED spot curing lamp heads

The controller is responsible for setting curing time, operating modes, and managing input/output signals. Each UV LED lamp head emits stable UV light, precisely focused on the designated curing area.

The curing process is based on a photochemical reaction: when UV-sensitive materials are exposed to UV light, they solidify almost instantly without the need for prolonged heating.

4. Key advantages of the H86 4-head Spot Curing System

Compared with conventional models, the H86 4-head Spot Cure System is optimized for both technical performance and real-world operation.

Flexible connectivity

The system integrates smoothly with PLCs and external control devices, allowing users to easily configure curing time for each production stage.

Multiple intelligent operating modes

It supports cycle-based curing triggered by signals or continuous curing while input signals are active, making it suitable for various production line configurations.

Active status monitoring

The system can detect abnormal conditions of UV LED lamp heads and output operational status signals, ensuring seamless coordination with robots, conveyors, or assembly equipment.

High operational stability

By using high-quality UV LED light sources, the system maintains consistent irradiation intensity and minimizes performance degradation over long-term operation.

5. Practical production applications

The Spot Cure System is widely used across multiple industries, including:

- UV adhesive curing for camera modules and sensors

- Fixation of electronic components and PCB assemblies

- UV ink curing for fine-detail printing

- Temporary bonding during assembly processes

- Thin coating curing on engineering plastics or small metal parts

With four independent lamp heads, the H86 model is especially suitable for products requiring multiple curing points simultaneously.

6. Comparison between 4-head and 8-head Spot Curing Systems

When selecting a Spot Curing Machine, manufacturers often compare 4-head and 8-head configurations. Below is a basic comparison:

Number of lamp heads

- 4-head system: suitable for medium output with compact layout

- 8-head system: supports high-volume curing with multiple simultaneous points

Initial investment cost

- 4-head system: lower upfront cost, easier budget optimization

- 8-head system: higher price due to increased lamp count and power capacity

Operating cost

- 4-head system: lower power consumption and maintenance cost

- 8-head system: higher energy use and higher replacement cost for components

Flexibility

- 4-head system: easy adjustment, suitable for diverse product types

- 8-head system: optimal for uniform products with large-scale output

For most small and medium-sized manufacturers, the H86 4-head Spot Curing System offers the best balance between performance and cost.

7. How to choose the right 4-head Spot Curing System

To select the most suitable Spot Curing System, manufacturers should consider the following factors:

- Number of curing points per product: determines the required number of lamp heads

- Production cycle time: high-speed lines may require more curing heads

- Installation space: 4-head systems are compact and easy to install in limited spaces

- Investment budget: balance equipment cost, operating cost, and productivity gains

- Future scalability: choose systems that support automation integration and upgrades

8. Conclusion

As precision manufacturing and automation continue to advance, the Spot Curing System plays a critical role in improving product quality and production efficiency. With its optimized design, reasonable cost, and flexible integration capabilities, the H86 4-head Spot Curing Machine is an ideal solution for manufacturers seeking reliable, efficient, and scalable UV curing equipment.

Contact Ms Yuna for technical support!

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com

4 Channels Spot Curing System

The H86 4-head Spot Curing System provides accurate UV LED point curing for small and heat-sensitive components. It offers stable performance, flexible control, and easy integration into modern production lines.

Product SKU: COUSZCVDH86E

Product Brand: COUSZ

Product Currency: VND

Product Price: 6888

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

Emily –

Fast delivery and great support.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com