365nm UV LED Curing Lamp – A Precise and Stable Adhesive Curing Solution

In high-precision manufacturing industries such as electronics, camera modules, and medical devices, curing speed, bonding strength, and process stability are critical requirements. The 365nm UV LED Curing Lamp has become a preferred solution for many manufacturers thanks to its strong photochemical activation capability, precise curing control, and easy integration into automated production lines.

With a dedicated wavelength, compact design, and reliable performance, this technology is rapidly becoming a standard in modern UV adhesive curing applications.

1. Overview of the 365nm UV LED Curing Lamp

The 365nm UV LED Curing Machine emits ultraviolet light at a wavelength of 365 nanometers, specifically optimized for curing high-reactivity UV adhesives. When the adhesive is exposed to 365nm UV light, photoinitiators are activated, triggering rapid polymerization and forming a strong, fully cured bond.

Compared with conventional thermal curing methods, UV adhesive curing offers several advantages:

-

Ultra-fast curing speed

-

No material deformation

-

High and stable bonding strength

-

Ideal for continuous and automated production

As a result, the 365nm UV LED Curing Systems is particularly suitable for applications requiring high precision and repeatable curing quality.

2. Basic Structure of the 365nm UV LED Curing Lamp

A standard UV adhesive curing system typically consists of the following main components:

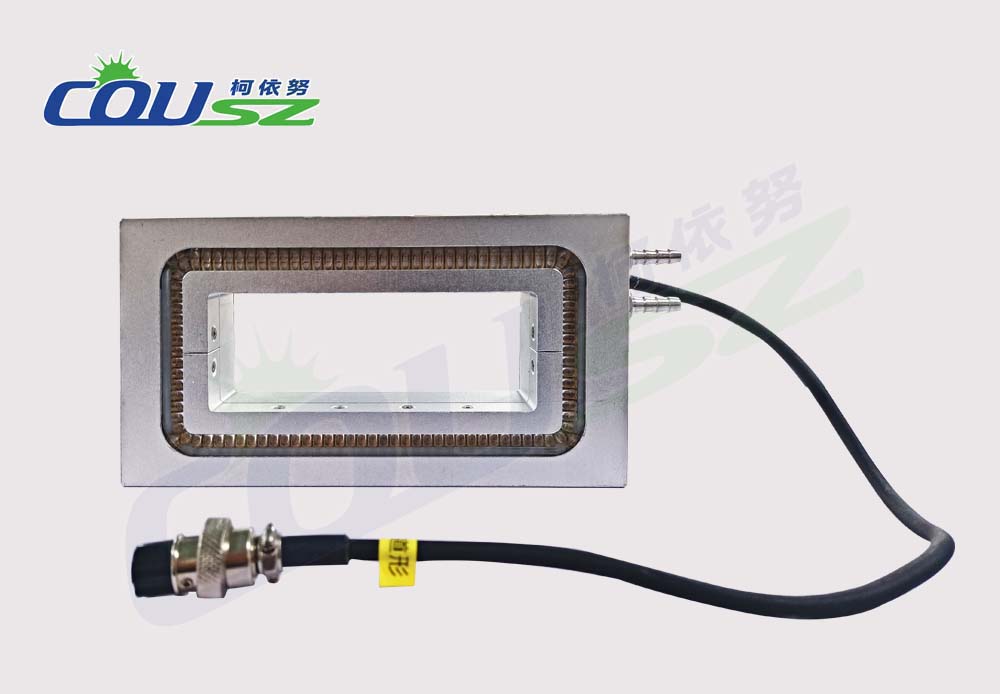

2.1. 365nm UV LED Light Source

-

Concentrated UV emission at 365nm

-

Stable light output with minimal degradation

-

Long service life and energy-efficient operation

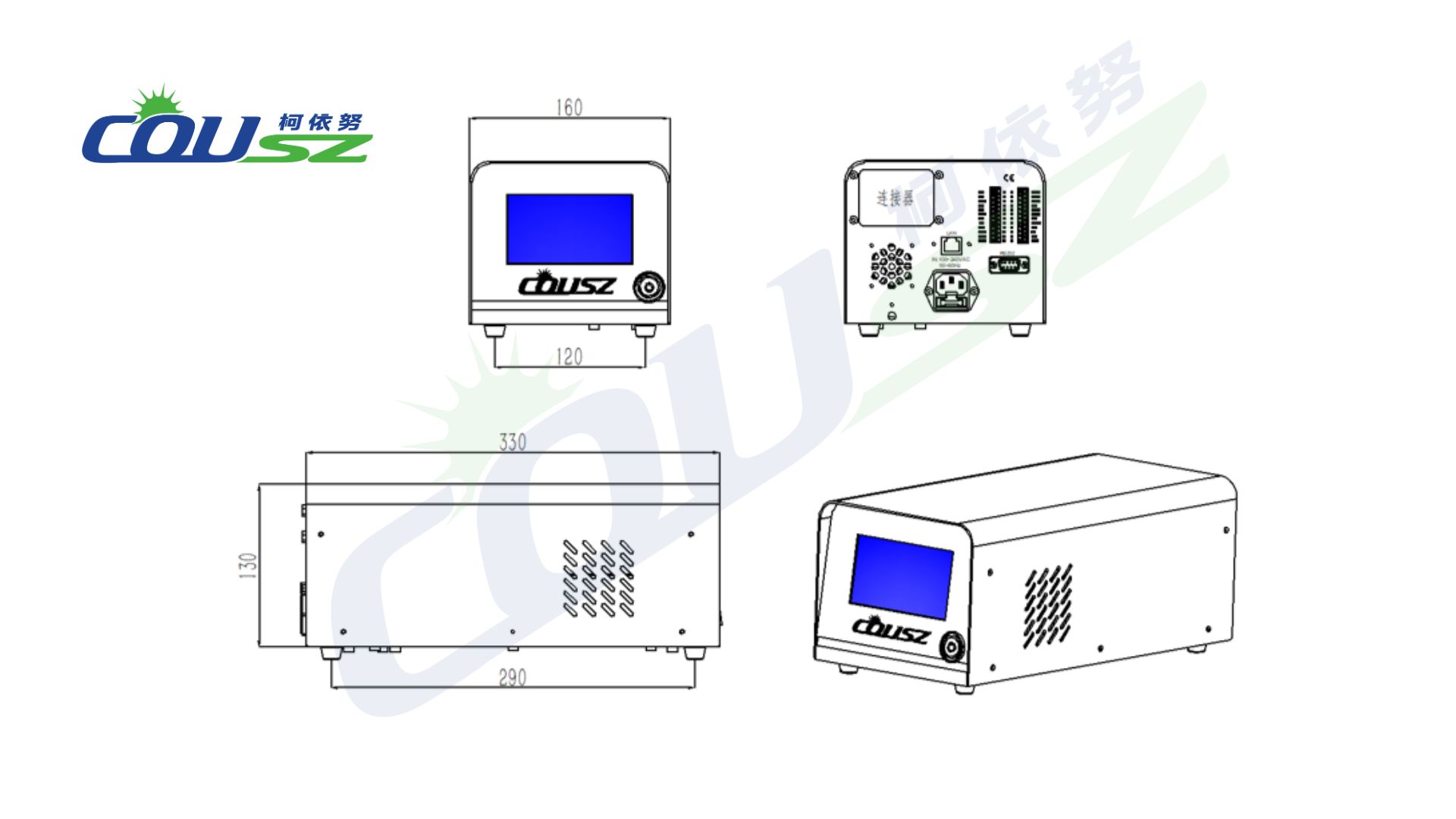

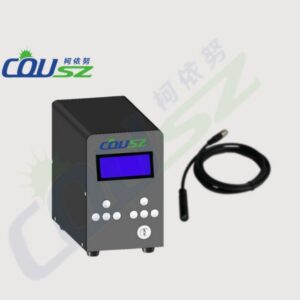

2.2. Control System

-

Flexible adjustment of irradiation power

-

Programmable curing time for different applications

-

Easy connection to PLC or automation systems

2.3. Cooling System

-

Air cooling or hybrid cooling solutions

-

Maintains stable lamp head temperature

-

Extends LED lifespan and ensures system durability

3. Common UV Wavelengths Used in Adhesive Curing

In UV adhesive curing technology, multiple wavelengths are used depending on adhesive properties:

-

365nm: Excellent penetration depth and strong photochemical reaction, widely used in technical adhesive curing

-

385nm: Balanced penetration and efficiency, suitable for various UV adhesives

-

395nm: Closer to visible light, lower heat generation, ideal for heat-sensitive materials

-

405nm: Used for special UV adhesives or applications requiring softer light

Among these options, the 365nm UV LED Curing Lamp remains the preferred choice for applications demanding high curing strength and long-term reliability.

4. Practical Applications of the 365nm UV LED Curing Lamp

The system is widely used across different products and curing positions, including:

-

UV adhesive bonding for camera modules and optical sensors

-

Assembly of electronic components and PCB boards

-

Fixation of small parts in medical devices

-

Precision bonding for mechanical and electronic components

-

Localized curing areas without affecting surrounding regions

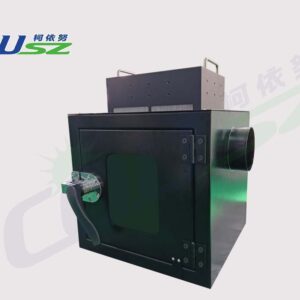

Its compact design allows flexible installation at individual curing stations or seamless integration into automated production lines.

365nm UV LED Curing Lamp Solutions with COUSZ

Selecting the right 365nm UV Curing Lamp depends not only on wavelength, but also on adhesive type, adhesive thickness, curing time, and production line configuration.

👉 For professional consultation and optimized curing solutions, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Excellent overall experience.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com