UV Flood Curing System: Reliable UV Curing Solution for Manufacturing

A UV Flood Curing System is a high-performance UV curing solution designed to irradiate multiple curing points or an entire product surface simultaneously within a single exposure cycle. With its ability to deliver high-intensity ultraviolet energy over a wide and uniform area, this technology has become a preferred choice across printing, electronics, industrial coating, and precision manufacturing industries—where speed, consistency, and curing uniformity are critical.

As production lines continue to scale and quality standards tighten, the UV Flood Curing System plays an increasingly strategic role in ensuring stable output, reduced cycle times, and long-term operational efficiency.

1. Overview of UV Flood Curing Technology

In UV curing technology, curing methods are generally divided into two categories: Spot Curing and Flood Curing. The UV Flood Curing System belongs to the latter, characterized by its wide irradiation area and evenly distributed UV energy.

This makes it particularly suitable for medium to large-sized products or applications requiring the curing of multiple areas at the same time. According to RadTech International, global UV curing adoption continues to grow due to its ability to reduce curing time from minutes to seconds while achieving near-zero VOC emissions compared to thermal drying.

Within this landscape, the UV Flood Curing System is widely recognized for its efficiency and reliability in continuous production environments.

2. How a UV Flood Curing System Works

A UV Flood Curing System operates by emitting ultraviolet radiation at specific wavelengths—typically UVA, UVB, or UV LED—to initiate a photopolymerization reaction within UV adhesives, inks, or coatings.

The curing process consists of three key stages:

– High-intensity UV radiation is generated by the lamp

– UV energy activates photoinitiators in the material

– Rapid polymerization and curing occur almost instantly

Technical documentation from IST Metz and Heraeus indicates that UV curing systems can achieve energy conversion efficiencies exceeding 90%, making them significantly more energy-efficient than conventional thermal drying methods.

3. Why UV Flood Curing Systems Are Widely Used

The growing popularity of the UV Flood Curing System is driven by a combination of performance, productivity, and quality advantages.

– Uniform curing over large areas: Unlike spot curing, flood curing ensures consistent UV energy distribution, minimizing defects such as incomplete curing, peeling, or uneven adhesion.

– Ideal for automated production lines: According to the European Printing Industry Federation, over 70% of modern UV printing lines in Europe rely on inline or flood UV curing systems to maintain speed and repeatability.

– Higher production throughput: By curing multiple points simultaneously, a UV Flood Curing System can increase productivity by 20–40% compared to manual or semi-automatic curing methods.

4. Industrial Applications of UV Flood Curing Systems

Today, UV Flood Curing Systems are widely used across multiple industries:

– Industrial printing (offset, flexographic, UV screen printing)

– Electronics manufacturing and PCB assembly

– UV adhesive bonding in precision mechanical assembly

– Surface coating and protective finishes

– High-end packaging and label production

According to Smithers Pira, the global UV curing market is expected to exceed USD 7.5 billion by 2030, with industrial UV curing systems accounting for a growing share.

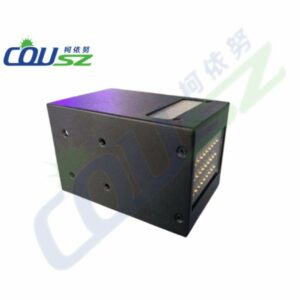

5. Basic Structure of a UV Flood Curing System

A standard UV Flood Curing System typically consists of the following core components:

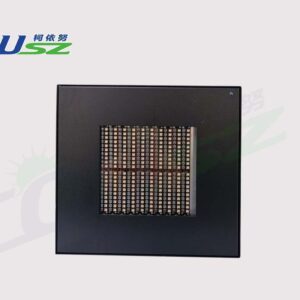

– UV light source (mercury lamp or UV LED)

– Shielded irradiation chamber to prevent UV leakage

– Cooling system (air or heat sink)

– Power and intensity control unit

– Structural frame and protective housing

Each component is engineered to ensure stable UV output, operational safety, and long service life.

6. Key Factors When Selecting a UV Flood Curing System

Choosing the right UV Flood Curing System requires careful evaluation of both technical and operational factors:

– Type of UV adhesive, ink, or coating used

– Required curing area and surface size

– Production line speed and throughput

– Available power supply and installation space

– Safety and compliance requirements

According to ISO 12647 guidelines for print quality control, stable UV energy output is essential for maintaining consistent product quality.

7. UV Flood Curing System Product Portfolio

Modern UV Flood Curing Systems are available in multiple configurations to meet different production needs:

– CVM3030 UV Flood Lamp: Designed for compact and medium-sized curing areas, offering stable UV output and high curing efficiency.

– CVM1002 UV Curing Floor Machine: A floor-mounted solution suitable for large workpieces and industrial-scale operations.

– UV Flood Light Bulb: A critical consumable component used in traditional UV flood curing setups, ensuring consistent irradiation.

– CVM365 UV Flood Curing Lamp: Operating at 365 nm, this model is compatible with most industrial UV adhesives and coatings.

– UV LED Flood Curing Lamp: Provides instant on/off functionality, reduced energy consumption, and long operational lifespan.

– CVM405 UV Glue Curing Machine: Optimized for next-generation UV adhesives requiring 405 nm wavelength and low thermal impact.

These models support a wide range of production scales, from semi-automatic workstations to fully automated industrial lines.

8. Safety and Standards for UV Flood Curing Systems

Due to the use of high-intensity UV radiation, UV Flood Curing Systems must comply with strict safety standards:

– Fully enclosed curing chambers

– UV-protective eyewear for operators

– Effective UV leakage control

– Comprehensive operator training

According to OSHA guidelines, proper UV safety compliance can reduce radiation-related risks by more than 80%.

Why Choose Our UV Flood Curing Systems?

We do more than supply equipment—we deliver complete UV curing solutions. With a comprehensive portfolio ranging from CVM3030 to CVM405, our customers benefit from:

– Verified curing accuracy: Each system is tested using calibrated UV measurement instruments before delivery

– Professional technical consulting: Wavelength and power selection based on real adhesive and material samples

– Reliable after-sales support: Genuine spare parts and responsive technical service teams

Conclusion

A UV Flood Curing System is a smart investment for manufacturers seeking high efficiency, uniform curing quality, and scalable production performance. With advanced systems such as the CVM365 UV Flood Curing Lamp and UV LED Flood Curing Lamp, businesses can significantly improve product quality while reducing defects caused by incomplete curing.

Looking to test your actual UV adhesive samples on a professional UV Flood Curing System?

Contact us today for expert technical consultation and a customized quotation tailored to your production needs.

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt