UV Curing Oven: A Complete Guide for High-Speed and Reliable Industrial Curing

A UV Curing Oven is a specialized industrial drying system that uses ultraviolet light to rapidly cure UV adhesives, printing inks, surface coatings, and other UV-reactive materials. Thanks to its fast curing speed, excellent uniformity, precise temperature control, and stable operation, the UV Curing Oven has become a core piece of equipment in industries such as printing, electronics, precision engineering, plastics, and industrial packaging.

As manufacturers increasingly demand higher productivity, better quality consistency, and lower energy consumption, the UV Curing Oven is emerging as a superior alternative to traditional thermal drying methods. This article provides a comprehensive and practical overview of UV curing oven technology, covering operating principles, system classifications, industrial applications, selection criteria, and long-term benefits.

1. Overview of UV Curing Oven Technology in Modern Production Lines

In modern industrial manufacturing, speed and consistency are critical competitive advantages. The UV Curing Oven plays an essential role in achieving both. Unlike conventional hot-air or infrared ovens that rely on heat transfer, a UV curing oven uses ultraviolet radiation to trigger a photochemical reaction that hardens materials almost instantly.

Industry studies show that UV curing can reduce curing time from several minutes to just a few seconds while significantly lowering overall energy consumption. This makes the UV Curing Oven particularly suitable for automated and continuous production lines where uptime and throughput directly affect profitability.

1.1 What Is a UV Curing Oven?

A UV Curing Oven is an enclosed or semi-enclosed drying system equipped with UV light sources—either mercury lamps or UV LED modules—along with reflective chambers, cooling systems, and electronic controls. When products enter the UV chamber, ultraviolet energy initiates a curing reaction that transforms liquid UV materials into a solid state quickly and evenly.

Compared with spot UV curing devices or line-type UV systems, a UV curing oven offers several key advantages:

– Ability to cure multiple products simultaneously

– High curing uniformity across large surfaces

– Suitable for medium- to large-sized components

– Easy integration into production lines

Thanks to these advantages, the UV Curing Oven is widely used in industrial environments that require stable quality and repeatable results.

1.2 Working Principle of a UV Curing Oven

The operation of a UV Curing Oven is based on photopolymerization. When UV-reactive materials are exposed to ultraviolet light at suitable wavelengths—typically between 250 nm and 405 nm—photoinitiators inside the material absorb the energy and trigger polymer cross-linking reactions.

This process causes the material to harden almost instantly without heating the entire substrate.

A standard UV curing oven system usually includes:

– An enclosed UV chamber to prevent UV leakage

– UV lamps or UV LED modules

– Reflective surfaces to enhance irradiation efficiency

– Cooling fans or heat dissipation units

– A control panel for time, power, and safety settings

This structure ensures that the UV Curing Oven delivers high curing efficiency while maintaining operator safety and process stability.

1.3 Key Advantages of UV Curing Oven Compared with Traditional Drying Methods

Ultra-Fast Curing Speed

One of the most significant benefits of a UV Curing Oven is its speed. In many applications, curing time is reduced to just 1–5 seconds—dramatically faster than conventional thermal drying methods.

Energy Efficiency

A UV curing oven focuses energy directly on the UV-sensitive material rather than heating the surrounding air or substrate. As a result, energy savings of 30–60% are commonly reported compared to hot-air ovens.

Stable and Uniform Curing Quality

The enclosed design of a UV Curing Oven ensures consistent exposure and minimizes uneven curing, peeling, or incomplete hardening. This is especially important in electronics, medical devices, and precision manufacturing.

Environmentally Friendly

UV curing does not require solvent evaporation, significantly reducing VOC emissions. This makes the UV Curing Oven an environmentally responsible solution that supports green manufacturing initiatives.

2. Common Types of UV Curing Ovens

To meet diverse production requirements, UV curing ovens are available in multiple configurations. Below are the most common types used in industrial settings.

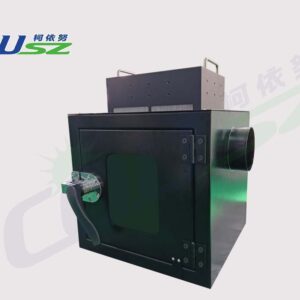

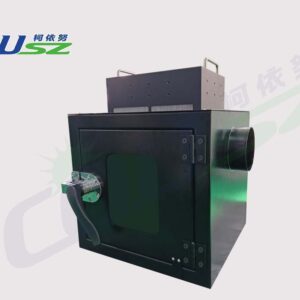

2.1 UV Chamber – Compact and Flexible UV Curing Solution

A UV chamber is a compact type of UV curing oven designed for batch processing or small- to medium-scale production. Products are placed inside the chamber and cured according to preset parameters.

Key advantages of a UV chamber include:

– Space-saving design

– Easy installation and operation

– Precise control of curing time and UV intensity

UV chambers are widely used in electronics assembly, jewelry manufacturing, printing, and material research laboratories.

2.2 UV Cabinet – UV Curing for Continuous Production Lines

A UV cabinet (UV curing oven in cabinet form) is designed for continuous or semi-continuous production. It often integrates conveyors or automated product handling systems, allowing items to pass through the curing zone smoothly.

This type of UV curing oven is ideal for:

– High-volume manufacturing

– Products requiring consistent, repeatable curing

– Highly automated production environments

With stable 24/7 operation, a UV cabinet significantly improves productivity while reducing labor costs.

2.3 UV Curing Cabinet – Enhanced Safety and Performance Control

A UV curing cabinet places strong emphasis on operator safety and process reliability. The curing chamber is fully shielded to prevent UV radiation leakage.

Typical features include:

– Safety doors with automatic shut-off

– Highly reflective interior surfaces

– Efficient cooling systems

Because of these safety-focused features, the UV curing cabinet is widely adopted in factories with strict occupational safety standards.

3. Industrial Applications of UV Curing Oven Technology

The versatility of the UV Curing Oven allows it to be used across a wide range of industries.

Printing Industry: In printing, a UV curing oven enables instant ink drying, allowing printed products to move directly to the next processing stage without smudging or waiting time.

Electronics Manufacturing: In electronics, UV curing ovens are used to cure adhesives and protective coatings on circuit boards, sensors, and optical modules without damaging heat-sensitive components.

Industrial Coatings: UV curing ovens are widely applied in surface coating processes for plastics, metals, and composite materials, providing durable, scratch-resistant finishes.

Packaging and Medical Devices: The UV Curing Oven is also essential in packaging and medical manufacturing, where cleanliness, consistency, and material integrity are critical.

4. How to Choose the Right UV Curing Oven

Selecting the right UV curing oven requires careful evaluation of several factors:

– Product size and production volume

– Type of UV-reactive material

– Required UV wavelength and lamp power

– Level of automation in the production line

– Safety and environmental compliance requirements

Choosing the correct UV Curing Oven not only improves curing performance but also extends equipment lifespan and reduces operational costs.

5. Long-Term Benefits of Investing in a UV Curing Oven

Companies that invest in a UV curing oven typically experience measurable improvements:

– Faster production cycles

– Lower energy consumption

– Reduced defect rates

– Improved product quality consistency

Over time, these benefits translate into higher profitability and stronger market competitiveness.

Conclusion

The UV Curing Oven represents a modern, efficient, and environmentally responsible curing solution for industrial manufacturing. Whether implemented as a UV chamber, UV cabinet, or UV curing cabinet, this technology offers unmatched speed, precision, and energy efficiency.

By selecting the right UV curing oven for your specific application, manufacturers can significantly improve product quality, reduce operating costs, and future-proof their production lines in an increasingly competitive industrial landscape.

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt