Advanced Line UV Cure Systems for High-Precision Industrial Curing

Line UV Cure Systems are specialized UV curing solutions designed for industrial production lines that require high-precision curing along narrow, straight paths. Unlike flood or area UV curing machines, these systems focus UV energy into a defined linear zone, making them ideal for curing UV adhesives, inks, and coatings applied in thin lines or precise patterns.

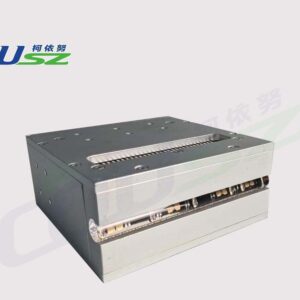

COUSZ develops and supplies industrial-grade Line UV Cure Systems that combine stable UV output, robust mechanical design, and seamless integration into automated production lines, helping manufacturers optimize productivity and long-term operational reliability.

1. Overview of Line UV Cure Systems

In industrial environments where curing accuracy directly affects product quality, Line UV Cure Systems offer a clear advantage over conventional wide-area UV curing equipment. These systems generate UV radiation concentrated into a narrow line, allowing manufacturers to cure specific edges, seams, or adhesive paths without exposing unnecessary areas.

According to RadTech International, UV curing technology can reduce processing time by 50–70% compared with traditional thermal drying methods, while significantly lowering VOC emissions. Within this market, Line UV Cure Systems continue to gain traction due to their ability to deliver precise curing with reduced energy loss.

Typical production scenarios using Line UV Cure Systems include:

– UV adhesive curing along defined lines

– Digital ink curing in narrow patterns

– Protective edge coating curing

– Electronics, optical, and medical device manufacturing

By focusing energy only where required, Line UV Cure Systems help manufacturers achieve both process efficiency and consistent product quality.

2. Working Principle of Line UV Cure Systems

The operating principle of Line UV Cure Systems is based on the emission of high-intensity UV radiation concentrated along a fixed linear length. When UV-sensitive adhesives, inks, or coatings are exposed to this energy, a photochemical reaction is triggered, causing the material to cure almost instantly.

Compared to flood UV curing machines, Line UV Cure Systems offer several technical advantages:

– Concentrated UV energy with minimal waste

– Reduced thermal influence on surrounding components

– Precise control over curing position

– Ideal for small, complex, or delicate parts

Data from Heraeus Noblelight indicates that focused UV curing solutions can reduce energy consumption by up to 30% in precision adhesive curing applications. This makes Line UV Cure Systems particularly suitable for manufacturers seeking high efficiency with controlled heat exposure.

3. Core Structure of Line UV Cure Systems

A standard Line UV Cure System typically consists of the following key components:

– UV light source: Determines wavelength and curing intensity

– Reflector and optical lens system: Shapes the UV beam into a uniform linear profile

– Cooling system: Maintains stable operating temperature and extends equipment lifespan

– Power and control unit: Enables precise adjustment of UV output

Depending on application requirements, Line UV Cure Systems may utilize traditional mercury UV lamps or advanced UV LED technology. Common wavelengths include UVA 365 nm and 385–405 nm for UV LED curing, ensuring compatibility with a wide range of UV-curable materials.

In automated production environments, Line UV Cure Systems are often integrated with conveyor systems or robotic arms, ensuring synchronized curing at high production speeds.

4. Key Advantages of Line UV Cure Systems

Line UV Cure Systems deliver significant operational and economic benefits to manufacturers. One of the most notable advantages is precision curing, which prevents over-exposure and protects non-target areas from unnecessary UV radiation.

Research from ACM Technology shows that UV LED-based Line UV Cure Systems can achieve 20–40% higher energy efficiency compared with conventional mercury lamp systems. This contributes to lower operating costs and improved sustainability.

Additional advantages include:

– Faster production cycles

– Reduced defect rates

– Easy integration into automated lines

Consistent curing quality for high-precision applications

For manufacturers pursuing smart and sustainable production, Line UV Cure Systems provide a future-ready solution.

5. Industrial Applications of Line UV Cure Systems

Electronics Manufacturing

In electronics production, Line UV Cure Systems are widely used for curing adhesives that secure components, applying protective coatings to circuit boards, and sealing sensitive edges. Line curing ensures strong adhesion without affecting nearby components.

Printing and Packaging

In digital printing and packaging, Line UV Cure Systems cure inks along edges or fine graphic details, improving sharpness, durability, and color stability.

Medical and Optical Industries

Medical devices and optical components demand extreme precision and cleanliness. Line UV Cure Systems meet these requirements by delivering controlled curing with minimal heat generation.

According to MarketsandMarkets, the global UV curing market is expected to exceed USD 8 billion by 2027, with specialized solutions such as Line UV Cure Systems showing steady growth due to increasing demand for precision manufacturing.

6. COUSZ Line UV Cure Systems Product Portfolio

COUSZ offers a comprehensive range of Line UV Cure Systems designed to meet diverse industrial requirements.

– CVX200 UV Curing Machine: The CVX200 UV Curing Machine is ideal for standard line curing applications requiring stable performance and easy system integration. It is widely used for UV adhesive curing and ink drying in continuous production lines.

– CVX60 Led UV Curing System: The CVX60 Led UV Curing System features a compact design optimized for limited production spaces. Despite its small footprint, it delivers consistent UV output and high energy efficiency.

– CVX100 UV Light Curing Machine: The CVX100 UV Light Curing Machine is designed for higher-power applications, making it suitable for continuous industrial operations that demand reliable long-term performance.

– CVX120 UV Light Curing Lamp: The CVX120 UV Light Curing Lamp provides enhanced output stability and durability, ideal for demanding production environments with extended operating hours.

– UV Light Curing System: Beyond individual models, COUSZ also supplies customized UV Light Curing System solutions tailored to specific technical requirements, ensuring optimal curing performance for unique production challenges.

7. How to Choose the Right Line UV Cure Systems

Selecting the appropriate Line UV Cure Systems requires careful evaluation of several factors:

– Type of UV-curable adhesive, ink, or coating

– Production line speed

– Required curing line width

– UV wavelength and intensity requirements

Proper wavelength selection ensures complete and stable curing reactions. Additionally, cooling efficiency, component durability, and automation compatibility play a crucial role in long-term system reliability.

Industry recommendations suggest that choosing the correct Line UV Cure Systems can reduce maintenance costs by up to 25% over 3–5 years, making system selection a strategic investment decision.

Conclusion

Line UV Cure Systems represent a highly efficient and precise UV curing solution for modern industrial production. By concentrating UV energy along a defined line, these systems reduce power consumption, enhance curing accuracy, and integrate seamlessly into automated manufacturing environments.

With a comprehensive portfolio including the CVX200 UV Curing Machine, CVX60 Led UV Curing System, CVX100 UV Light Curing Machine, CVX120 UV Light Curing Lamp, and customized UV Light Curing System solutions, COUSZ empowers manufacturers to achieve superior product quality and long-term operational efficiency.

Investing in the right Line UV Cure Systems is not only a step toward higher productivity but also a commitment to sustainable, precision-driven manufacturing for the future.

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt