A custom UV cure system is a tailored UV curing solution designed to meet specific technical, space, and performance requirements that standard machines cannot fulfill. By optimizing curing efficiency, reducing energy consumption, and ensuring stable output quality, custom UV curing systems help manufacturers achieve higher precision and long-term production efficiency across demanding industries such as electronics, medical devices, automotive, optics, and industrial printing.

1. Custom UV Cure System: A Breakthrough Solution for Industrial Production

In real-world manufacturing environments, no two production lines are exactly the same. Product dimensions, conveyor speed, UV adhesive type, coating thickness, and installation space all vary significantly. These variations explain why a custom UV cure system is now a preferred choice in high-precision industries.

According to global market research from MarketsandMarkets, the UV curing industry has exceeded USD 6 billion in market size, with an annual growth rate of over 12%. Within this expansion, customized UV curing solutions are gaining a larger market share due to increasing demand for tailored production efficiency.

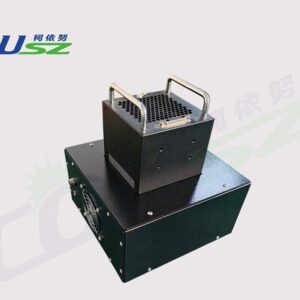

At COUSZ, custom UV cure system solutions include the following product categories:

– UV ink curing machine

– UV LED curing lamp (365nm)

– UV mercury lamp

– Mercury lamp

– Mercury UV light

Each system is designed to integrate seamlessly into existing production lines while delivering consistent curing performance.

2. Why Do Businesses Need a Custom UV Cure System?

2.1 When Standard UV Curing Machines Are No Longer Sufficient

Standard UV curing machines are typically designed for mass applications and general use. However, many manufacturers face challenges such as:

– Complex product geometries with hidden or shadowed curing areas

– Non-uniform curing zones requiring high positional accuracy

– Strict temperature limitations to protect heat-sensitive components

– Variable production speeds across different process stages

In these scenarios, a custom UV cure system becomes essential to achieve 100% curing consistency and quality assurance.

2.2 Performance Optimization and Energy Efficiency

According to RadTech International, UV curing systems designed specifically for their applications can deliver significant performance improvements:

– 20–35% reduction in annual energy consumption

– 15–25% improvement in curing efficiency

– Elimination of under-curing and uneven curing defects

By deploying a custom UV cure system, manufacturers can balance high curing output with lower operational costs, contributing directly to sustainable production goals.

3. Comparison: Standard UV Curing Machines vs. Custom UV Cure Systems

| Feature | Standard UV Curing Machine | Custom UV Cure System |

|---|---|---|

| System Structure | Fixed manufacturer design | 100% tailored to production line |

| Compatibility | Moderate, requires process adjustment | Perfect in-line integration |

| Energy Efficiency | Potential energy waste | Optimized for curing area |

| Process Stability | Product-dependent | Up to 30% higher stability |

This comparison clearly shows how a custom UV cure system offers superior adaptability and long-term value.

4. Core Design Elements of a Custom UV Cure System

4.1 Wavelength Configuration Based on Material Properties

Different UV adhesives and substrates react optimally at specific wavelengths. A custom UV cure system allows precise wavelength configuration, including:

– UVA 365 nm for deep penetration curing

– 385–395 nm for high-speed surface curing

– Hybrid solutions combining mercury lamps and UV LED technology

This flexibility ensures the highest curing performance for each material type.

4.2 Irradiance and Power Density Control

Accurate power control is essential for achieving consistent curing results. A custom UV cure system can be configured for:

– 100–1000 mW/cm² for delicate electronic components

– Above 2000 mW/cm² for thick coatings and protective layers

This level of control is impossible to achieve with generic UV curing equipment.

4.3 Mechanical Integration and Factory Space Optimization

Space constraints are a major challenge in modern factories. According to UV Solutions Group, over 60% of manufacturers choose a custom UV cure system primarily to optimize installation in confined or complex production areas.

Customized mechanical design ensures:

– Seamless integration into existing conveyor systems

– Vertical, horizontal, or angled lamp arrangements

– Minimal footprint without sacrificing curing efficiency

4.4 Thermal Management and Product Protection

For heat-sensitive materials such as engineered plastics or medical components, temperature control is critical. A custom UV cure system enables:

– Complete separation of UV radiation and infrared heat

– Integrated air or water cooling modules

– Surface temperature control below 40–50°C

This ensures product safety while maintaining optimal curing speed.

5. Introduction to Key Products in Custom UV Cure Systems

UV Ink Curing Machine: The UV ink curing machine is designed for high-speed industrial printing applications, ensuring rapid ink curing on both flat and irregular surfaces. When integrated into a custom UV cure system, it delivers consistent color quality and excellent adhesion.

UV LED Curing Lamp (365nm): The UV LED curing lamp at 365nm provides energy-efficient, instant-on curing with minimal heat output. It is ideal for precision electronics, optical bonding, and medical device assembly within a custom UV cure system.

UV Mercury Lamp: A UV mercury lamp offers high-intensity broadband UV output, making it suitable for thick coatings and high-speed curing applications. It remains a key component in many custom UV cure system designs.

Mercury Lamp: The mercury lamp is widely used for traditional UV curing processes, providing stable output and long operational life. In a custom UV cure system, it can be optimized for specific curing zones.

Mercury UV Light: Mercury UV light solutions are commonly applied in industrial coating, printing, and bonding processes. When tailored as part of a custom UV cure system, they deliver reliable and uniform curing performance.

6. Real-World Applications of Custom UV Cure Systems

Thanks to their flexibility, custom UV cure system solutions are widely adopted across advanced industries:

– Semiconductor manufacturing: Micrometer-level chip bonding

– Medical industry: UV curing of syringes, catheters, and disposable devices

– Automotive sector: Curing complex plastic interiors and lighting components

– Industrial printing: UV inkjet systems on uneven or curved surfaces

Each application benefits from the precision, efficiency, and reliability of a Custom UV Cure System.

Conclusion: Custom UV Cure System as a Strategic Investment

A custom UV cure system is not merely a piece of equipment—it is a comprehensive technological solution built around the core operational goals of your business. As modern manufacturing continues to prioritize efficiency, energy savings, and absolute precision, customized UV curing solutions represent a strategic pathway to enhanced competitiveness.

If standard UV curing machines are limiting your production potential, it is time to consider a custom UV cure system tailored to your exact requirements.

Contact us today to receive expert consultation and discover the most optimized custom UV cure system for your application.

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt