UV Curing Systems: Advanced UV Adhesive Curing Solutions for Modern Manufacturing

UV curing systems are widely recognized as one of the most efficient solutions for curing UV adhesives and coating materials in modern industrial manufacturing. With advantages such as ultra-fast curing speed, precise process control, and significant energy savings, uv curing systems have become essential UV curing equipment in many factories worldwide.

Today, manufacturers across electronics, printing, packaging, medical devices, and precision engineering increasingly rely on UV curing systems to improve product quality, reduce production time, and optimize operating costs. Whether configured as standalone UV curing machines or fully integrated UV curing systems, this technology plays a critical role in high-performance industrial processes.

1. What Are UV Curing Systems?

UV curing systems are curing solutions that use ultraviolet (UV) radiation to initiate photochemical reactions, allowing UV adhesives, inks, and coatings to cure rapidly. When exposed to UV light at specific wavelengths, photoinitiators within the adhesive or coating activate, transforming the material from a liquid or semi-liquid state into a solid within seconds.

Compared to conventional thermal drying methods, UV curing systems offer dramatically faster curing speeds, minimal heat generation, and superior surface quality. This makes UV curing systems ideal for heat-sensitive substrates and precision components.

In real production environments, UV curing systems are often integrated into complete UV curing lines, suitable for both manual workstations and fully automated production lines.

2. The Role of UV Curing Systems in Modern Manufacturing

In modern manufacturing, UV curing systems play a key role in enhancing productivity and ensuring consistent product quality. By precisely controlling UV intensity, exposure time, and wavelength, UV curing systems help manufacturers reduce defects, improve bonding strength, and shorten production cycles.

For industries that demand high accuracy and repeatability, UV curing systems provide a reliable solution to ensure uniform curing performance and long-term adhesive durability. As production standards continue to rise, UV curing systems are increasingly viewed as a core component of advanced manufacturing processes.

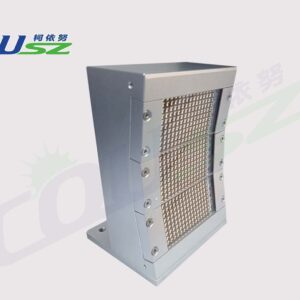

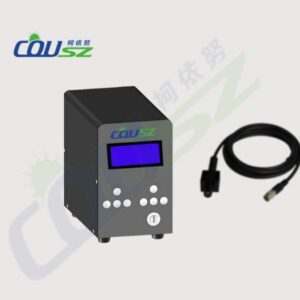

3. Basic Structure of UV Curing Equipment

A standard UV curing system typically consists of the following key components:

– UV light source (UV LED or mercury lamp)

– UV curing chamber or UV conveyor system

– Cooling and heat dissipation system

– Power supply and control unit

– Machine frame and safety protection system

The coordinated operation of these components ensures stable performance and allows UV curing systems to meet a wide range of curing requirements across different applications.

4. Working Principle of UV Curing Systems

The working principle of UV curing systems is based on photopolymerization. When UV adhesive or coating materials are exposed to UV light with the appropriate wavelength, photoinitiators absorb the energy and trigger polymerization reactions.

This process enables UV curing systems to achieve extremely high curing efficiency while minimizing thermal impact on sensitive materials. As a result, UV curing systems are widely used for plastics, electronic components, optical parts, and other heat-sensitive substrates.

5. Key Advantages of UV Curing Systems

Compared with traditional curing and drying methods, UV curing systems offer several clear advantages:

Fast curing speed: UV adhesives and coatings cure almost instantly, significantly increasing production throughput and reducing waiting time.

Energy efficiency: Especially with LED UV technology, UV curing systems consume less energy, generate less heat, and offer longer service life.

Consistent curing quality: UV curing systems ensure strong adhesion, uniform surfaces, and reduced risks of peeling or delamination.

Material safety: Low thermal output makes UV curing systems suitable for plastics, electronic assemblies, and temperature-sensitive materials.

Easy system integration: UV curing systems can operate as standalone units or be integrated into automated UV curing lines.

6. Industrial Applications of UV Curing Systems

UV curing systems are widely applied across multiple industries:

Electronics manufacturing: Curing adhesives for electronic components, PCBs, camera modules, and sensors.

Printing and packaging: Curing UV inks, varnishes, and adhesives for labels, cartons, and flexible packaging.

Jewelry production: Fixing gemstones and small components with high precision and clean finishes.

Medical devices: Curing adhesives and coatings for medical equipment and disposable supplies.

Precision engineering: Bonding metal and non-metal parts with high strength and reliability.

These applications highlight the versatility and reliability of UV curing systems in demanding industrial environments.

7. Common Types of UV Curing Systems

COUSZ provides a comprehensive range of UV curing systems designed to meet diverse industrial requirements.

7.1 General UV Systems

– UV curing systems

– UV light curing system

– Custom UV cure system

– UV ink curing machine

7.2 Conveyor UV Systems

– CVY405 UV curing conveyor

– CVY218 UV light conveyor

– UV curing conveyor systems

– CVY10050 UV cure conveyor

– CVY200200 UV conveyor system

– UV conveyor curing systems

– CVL365 UV conveyor

– CVL395 UV machine conveyor belt

– UV light curing conveyor 365nm

– 405nm UV conveyor machine

– UV led curing conveyor

– CVY80100 UV lamp conveyor

7.3. Spot UV Curing

– Spot UV Curing System

– 365nm Spot UV Curing Machine

– Spot Curing Machine 405nm

– 4 Channels Spot Curing System

– LED UV Spot Curing System

– Spot UV Curing Equipment

– 8 Channels UV Spot Curing Lamp

– UV Curing Spot Light

7.4. Flood UV Curing

– UV Flood Curing System

– CVM3030 UV Flood Lamp

– CVM1002 UV curing floor machine

– CVM1001 UV flood light bulb

– CVM365 UV flood curing lamp

– CVM501 UV LED flood curing lamp

– CVM405 UV glue curing machine

7.5. UV Ovens & Chambers

– UV curing oven

– UV chamber

– UV cabinet

– UV curing cabinet

7.6. Line UV Curing

– UV cure systems

– CVX200 UV curing machine

– CVX60 LED UV curing system

– CVX100 UV light curing machine

– CVX120 UV light curing lamp

– UV light curing system

7.7. Industrial UV Systems

– Industrial UV curing tunnel

– UV light chamber

– UV curing chamber

7.8. UV Lamps & Bulbs

– UV LED curing lamp

– UV mercury lamp

– UV Mercury lamp

– Mercury UV light

8. How to Choose the Right UV Curing Systems

When selecting UV curing systems, manufacturers should carefully consider the following factors:

– Type of UV adhesive and required wavelength

– Product size, shape, and curing area

– Required curing power and production speed

– Scalability and future expansion of UV curing systems

– Long-term investment and operating costs

Choosing the right UV curing systems ensures optimal performance, consistent quality, and cost efficiency.

9. Operation and Maintenance of UV Curing Systems

Proper operation and maintenance are essential to ensure long-term reliability of UV curing systems:

– Regular inspection of UV light sources and cooling systems

– Cleaning of curing chambers and reflective surfaces

– Strict compliance with UV safety regulations

Timely replacement of components according to manufacturer recommendations

Well-maintained UV curing systems deliver stable performance and extended service life.

Conclusion

UV curing systems are fast, reliable, and efficient solutions for curing UV adhesives and coatings across a wide range of industrial applications. Investing in the right UV curing systems—whether UV curing machines, UV light curing equipment, or fully integrated UV curing systems—helps manufacturers improve product quality, reduce production costs, and strengthen their competitive advantage.

As industrial production continues to evolve, UV curing systems will remain a key technology driving efficiency, precision, and sustainability in modern manufacturing.

UV Curing Conveyor

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt