Ultraviolet Meter (UV Meters) – An Essential UV Control Device in Manufacturing

In industries that rely on UV curing technology—such as printing, electronics, UV adhesives, and surface coating—accurate control of UV energy plays a critical role. Ultraviolet Meter (UV Meters) are widely regarded as a global standard, enabling manufacturers to monitor, evaluate, and optimize UV system performance with high accuracy and long-term stability.

1. Overview of Ultraviolet Meter (UV Meters)

Ultraviolet Meter (UV Meters) are specialized measuring devices developed to ultraviolet energy measurement and analysis. These instruments are designed to measure UV intensity, total energy, and spectral distribution in industrial UV curing systems.

In real production environments, UV Meters act as the “monitoring brain” of the UV process, allowing engineers to accurately evaluate the amount of UV energy delivered to the material surface. This ensures consistent curing quality for UV adhesives, UV inks, and UV coatings, while minimizing defects and reducing operating costs.

2. Working principle of Ultraviolet Meter (UV Meters)

The operating principle of UV Meters is based on high-precision optical sensors that are calibrated for specific UV wavelength ranges. As the device passes through the UV irradiation zone, the sensors capture real-time measurement data.

Key parameters measured by UV Meters include:

-

UV intensity (mW/cm²)

-

Total UV energy (mJ/cm²)

-

UV exposure time

-

Energy distribution across different wavelength bands

After measurement, the data is stored in the device’s internal memory and can be transferred to a computer for advanced analysis. This helps operators detect potential issues at an early stage, such as UV lamp degradation, focal misalignment, or curing inconsistencies.

3. Multi-wavelength measurement capability

One of the most outstanding advantages of Ultraviolet Meter (UV Meters) is their ability to accurately measure multiple UV wavelength ranges. Depending on the model and sensor configuration, the device can measure:

-

365 nm: commonly used for UV adhesive curing, UV inks, and UV coatings

-

385 nm: widely applied in specialized surface treatment applications

-

395 nm: frequently used in UV ink curing for printing

-

405 nm: commonly used for UV adhesive curing

By independently measuring each wavelength band, UV Meters enable manufacturers to precisely evaluate the compatibility between the UV light source and the applied materials, preventing under-curing or over-curing.

4. Key features of Ultraviolet Meter (UV Meters)

Ultraviolet Meter (UV Meters) are highly valued for their advanced features, designed to meet the strict requirements of industrial production environments.

-

High measurement accuracy with excellent repeatability

-

Compact, heat-resistant design suitable for direct operation on conveyors

-

Real-time data logging with high sampling rates

-

Independent analysis of UVA, UVB, and UVC wavelength bands

-

Compatibility with various UV light sources, including mercury lamps, UV LED, and metal halide lamps

Thanks to these features, UV Meters have become indispensable tools in quality control systems and UV curing process optimization.

Conclusion

With high accuracy, multi-wavelength measurement capability across 365nm, 385nm, and 405nm ranges, and broad industrial applicability, UV Meters are essential measurement solutions for modern UV curing systems. These devices not only support reliable quality control but also contribute to improved efficiency and long-term sustainability across production lines.

Consultation & Quotation

Are you looking for professional advice on selecting the right Ultraviolet Meter (UV Meters) for your production line?

-

Contact person: Ms Yuna

-

Hotline: +84 965 535 345

-

Email: sales03@cousz.com

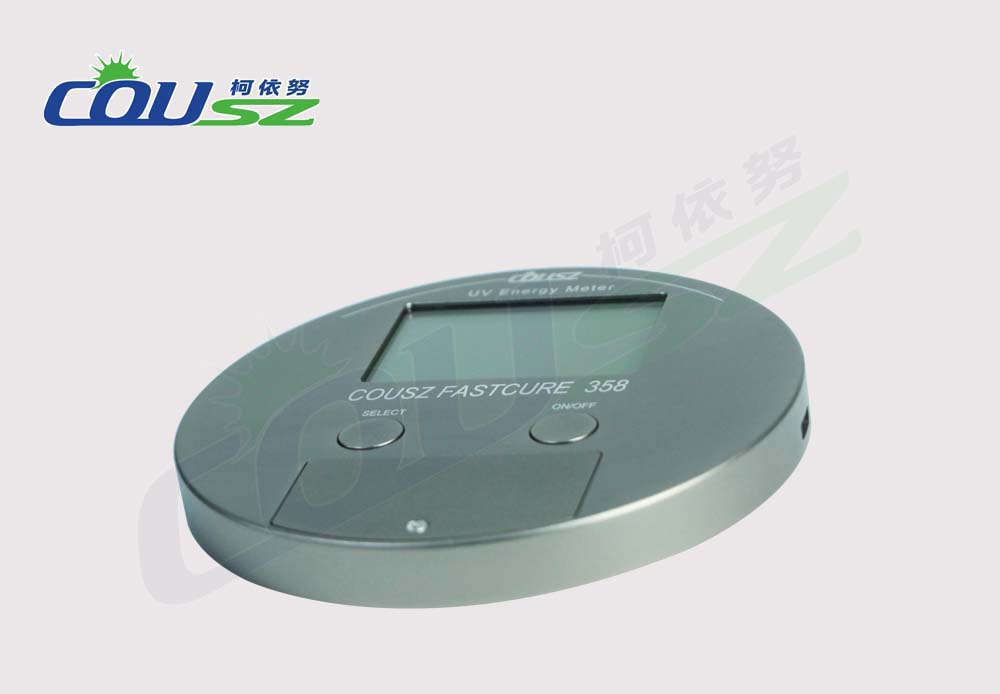

Ultraviolet Meter (UV Meters)

Ultraviolet Meter (UV Meters) ensure precise UV energy control, helping manufacturers optimize curing quality and system performance.

Product SKU: UVMETEREITV

Product Brand: COUSZ

Product Currency: VND

Product Price: 6868

Price Valid Until: 2025-12-28

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com

Brian –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com