CVC395 UV Machine Conveyor Belt – An Optimal UV Adhesive Curing Solution for Modern Production Lines

As manufacturing plants increasingly move toward automation, strict quality control, and productivity optimization, UV adhesive curing equipment is no longer a supplementary option but a critical link within the production line. The CVC395 UV Machine Conveyor Belt has been developed to meet the demand for continuous, stable, and safe UV adhesive curing, making it especially suitable for electronics, precision component assembly, and modern industrial manufacturing.

1. Overview of the CVC395 UV Machine Conveyor Belt

The CVC395 UV Machine Conveyor Belt is a conveyor-type UV adhesive curing system that utilizes 395 nm UV LED technology, allowing products to move continuously through the UV irradiation zone to complete the curing process.

Unlike manual curing methods or localized UV exposure, the CVC395 UV Conveyor operates based on an in-line principle, fully synchronized with the production line rhythm. This helps to:

-

Reduce curing waiting time

-

Minimize dependence on manual operations

-

Ensure consistent curing quality across products

As a result, the CVC395 UV Machine Conveyor Belt is commonly selected for production line upgrades or capacity expansion projects.

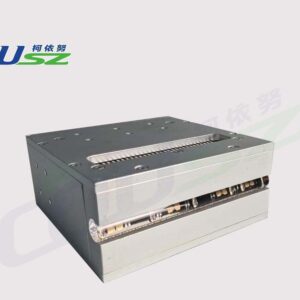

2. Structure of the CVC395 UV Machine Conveyor Belt

To meet long-term industrial operation requirements, the CVC395 UV Curing Conveyor Belt is designed with a robust structure optimized for seamless integration into automated production lines.

2.1 High-performance conveyor system

The conveyor system is the core of the CVC395 UV Machine Conveyor Belt, responsible for transporting products smoothly and consistently through the UV curing zone.

-

Adjustable conveyor speed suitable for various UV adhesives

-

High load capacity with durable, long-term operation

-

Smooth movement that minimizes vibration and protects curing quality

This design allows the CVC395 UV Machine Conveyor Belt to maintain stable performance even during continuous, high-volume operation.

2.2 Enclosed UV curing chamber

The curing chamber features an enclosed design that concentrates UV energy precisely where needed while minimizing UV leakage to the surrounding environment.

This not only improves curing efficiency but also enhances operator safety—an essential requirement in modern manufacturing facilities.

2.3 395 nm UV LED light system

The CVC395 UV Conveyor is equipped with 395 nm UV LED light sources, a widely adopted option in the electronics industry due to their ability to:

-

Deliver fast and efficient curing

-

Reduce heat generation, protecting sensitive components

-

Offer long LED lifespan and lower operating costs

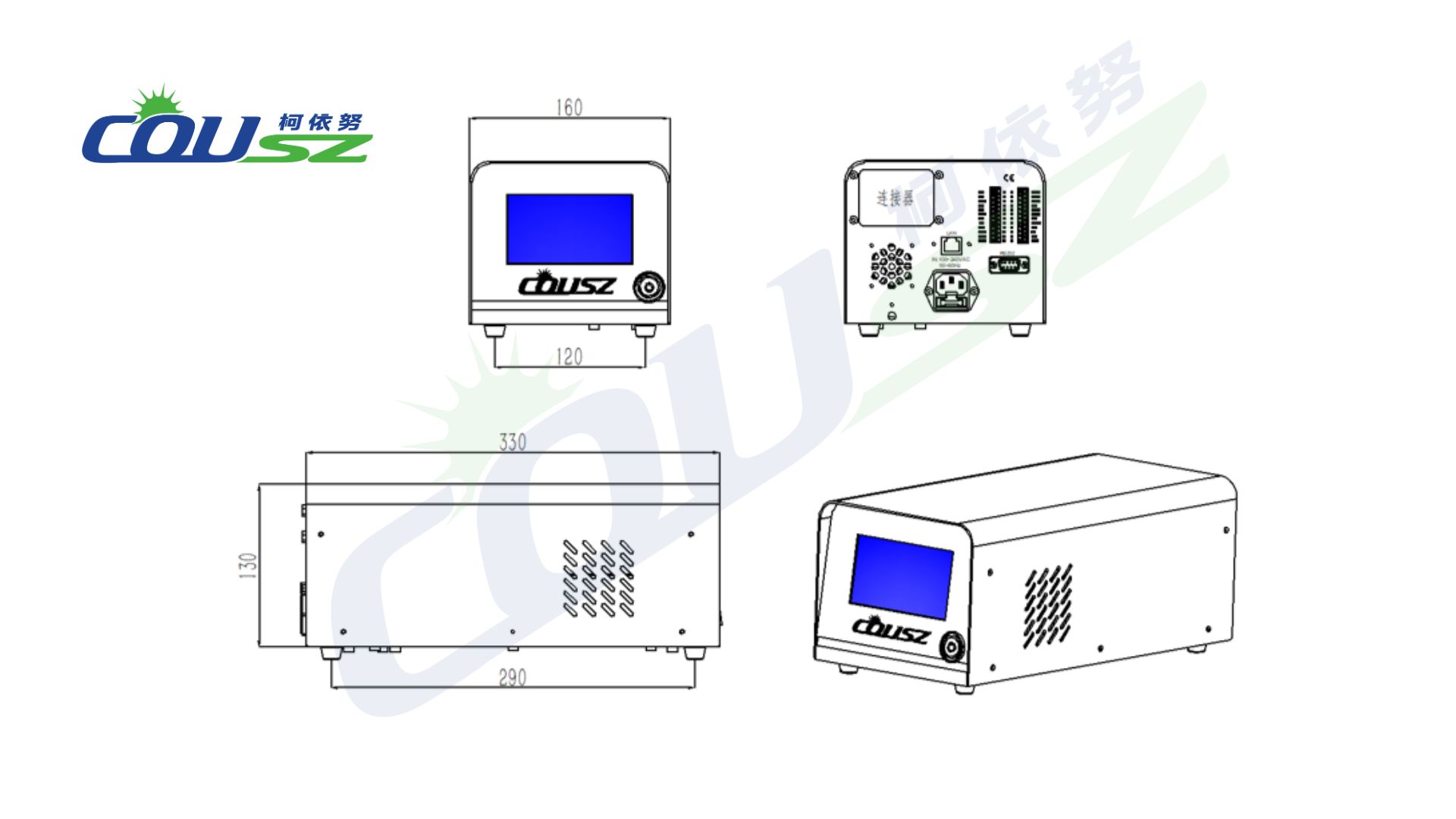

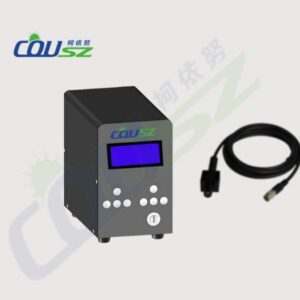

2.4 Controller system

POWER SUPPLY

| Specification | Description | Specification | Description |

|---|---|---|---|

| Dimensions (mm) | L330 × W160 × H130 | Power | 50 W |

| Cooling | Fan cooling | Input power | 100–240V AC, 50–60 Hz |

| Weight / Material | Approx. 3.5 kg, metal | Output power | 10%–100% |

| Setting lock | Password-protected advanced settings | Display & setting | Touchscreen; time, intensity |

| Number of LED light sources | 1–4 units | Control | Foot pedal, SCM, PLC, RS232 / RS485 / TCP |

| Alarm | Over-temperature and system fault alarms | Operating time | Accumulated usage tracking |

3. Benefits of UV curing cabinets in industrial manufacturing

The application of UV curing cabinets in general, and the CVC395 UV Machine Conveyor Belt in particular, delivers significant benefits to manufacturers:

-

Higher productivity: Continuous curing without interrupting production flow

-

Stable quality: Uniform UV adhesive curing reduces product defects

-

Space efficiency: Compact design suitable for factory layouts

-

Operational safety: Reduced direct exposure to UV radiation

-

Lower long-term costs: Minimal maintenance and extended equipment lifespan

These advantages make the CVC395 UV Machine Conveyor a valuable investment for manufacturers pursuing sustainable and efficient production.

4. Key features of the CVC395 UV Machine Conveyor Belt

Multi-language user interface

The CVC395 UV Machine Conveyor Belt is built on a modern interface platform supporting multiple languages, making it ideal for:

-

FDI enterprises

-

Factories with multinational technical teams

-

Export-oriented production lines

The intuitive interface enables operators to quickly adapt and operate the system accurately.

Intelligent alarm system

The intelligent alarm system is a notable strength of the CVC395 UV Machine Conveyor Belt, offering the ability to:

-

Automatically detect operational faults

-

Alert when temperature or parameters exceed safe limits

-

Support rapid troubleshooting and maintenance

This significantly reduces the risk of unexpected production downtime.

Multiple connectivity options

The CVC395 UV Machine Conveyor Belt supports a wide range of flexible connectivity methods, enabling easy integration with centralized factory control systems:

-

PLC

-

SCM

-

RS232 / RS485

-

TCP/IP

-

Foot pedal control

This flexibility allows the system to adapt seamlessly to both semi-automated and fully automated production lines.

Conclusion

With an optimized design for modern production lines, intelligent system integration, and long-term operational stability, the CVC395 UV Curing Conveyor is an ideal solution for manufacturers seeking an efficient, safe, and scalable UV adhesive curing system for future growth.

Consultation & quotation for the CVC395 UV Machine Conveyor Belt

👉 For detailed consultation and the most suitable configuration of the CVC395 UV Cure Conveyor Belt for your production line, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

CVC395 UV Machine Conveyor Belt

CVC395 UV Machine Conveyor Belt delivers stable, continuous UV adhesive curing for automated production lines in electronics and industry.

Product SKU: COUSZCVC007E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Smooth service from start to end.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com