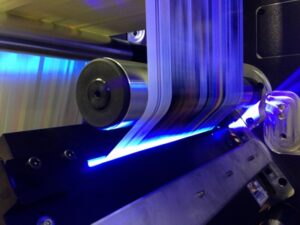

Discover the Power of LED UV Curing with Air Motion Systems

Air Motion Systems (AMS) is a leader in manufacturing advanced LED UV curing systems tailored for polymeric printing inks, coatings, adhesives, and more. In this article, we explore the benefits of UV LED curing technology for the printing, processing, and other industries. Get answers to common questions about this innovative technology and learn how it can transform your business.

Why Choose UV LED Curing? The Basics and Benefits

As a world-renowned provider of UV LED curing solutions, AMS has developed a patented LED UV system unmatched in the industry. Recognized for its flexibility and exceptional performance, our system delivers impressive advantages over traditional curing methods.

AMS provides UV LED curing solutions compatible with offset, digital, and flexographic presses, helping companies move away from conventional drying processes that can be hot, messy, and even toxic. Here are some key benefits of integrating UV LED curing into your operations:

- Instant Ink Curing: Say goodbye to drying time and powder usage—our system cures inks immediately upon application.

- Expanded Substrate Options: Print on a wider variety of materials, including plastics and other non-absorbent substrates, without sacrificing quality.

- Safe Thermal Printing: UV LED curing allows for high-quality results on heat-sensitive materials without damaging them.

- Eco-Friendly Processing: UV inks are solvent-free, meaning no volatile organic compounds (VOCs) are released, reducing environmental impact.

- Lower Energy Costs: By eliminating excessive heat, UV LED curing helps reduce energy costs and minimizes heat-related hazards.

- Enhanced Coatings and Effects: Achieve high-end effects, like drip or “penetration” textures, which add value to your prints and open up new creative possibilities.

These are just a few of the advantages UV LED curing offers. Regardless of your press type—whether offset, digital, or flexo—AMS’s technology enables immediate improvements to both print quality and environmental sustainability.

UV LED technology is improving printing processes for labels and packaging.

A Look at the History of UV LED Curing

While traditional UV curing has been around since the 1960s, using mercury arc lamps to initiate the polymerization process, UV LED curing represents a newer, cleaner, and more efficient evolution. Unlike mercury arc lamps, which require high energy and emit ozone, UV LED curing is a low-temperature, high-speed, solvent-free process that eliminates the need for ventilation systems and reduces harmful emissions. In fact, the EU’s Restriction of Hazardous Substances (RoHS II) rules now limit the use of heavy metals, including mercury, making UV LED curing an increasingly attractive option.

AMS pioneered this shift in 2009 by introducing the XP Series—the first truly scalable, high-power LED UV curing system. Built with advanced cooling technology, scalable UV LEDs, and precise collimating optics, our patented XP Series opened a new era of industrial curing and printing, delivering unmatched quality and sustainability.

Ready to Experience the Future of Printing with AMS?

Explore how AMS’s LED UV curing systems can redefine your printing, processing, and finishing capabilities. From cost-saving efficiencies to environmentally friendly outcomes, our technology is designed to meet the demands of today’s industries. Let us help you unlock new levels of quality, creativity, and sustainability.

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt