The Role of UV Curable Coatings in Mobile Phone Manufacturing

In recent years, rapid advancements in wireless communication technology have led to a surge in mobile phone designs. Phones today are more functional, durable, and aesthetically diverse, with designs that range from sleek and minimalist to bold and eye-catching. These improvements in both appearance and durability are largely thanks to the application of ultraviolet (UV) curable coatings in mobile phone production.

What is UV Curable Coating?

UV curable coatings are innovative, eco-friendly polymer coatings that use UV light as a curing energy source. This unique technology allows the coating’s components to chemically bond at room temperature without requiring organic solvents, creating a smooth, durable film without residual volatiles. As a result, UV curable coatings are non-toxic, energy-efficient, wear-resistant, and highly decorative, meeting the standards for green materials in the 21st century.

With a global trend toward environmental protection, many countries, including the U.S., Germany, Japan, and Italy, have legislated to limit high-VOC (volatile organic compound) emissions, driving a shift from traditional coatings to eco-friendly UV coatings. UV curing’s high efficiency and energy-saving benefits—such as fast curing without the need for heat—are ideal for streamlined production lines, contributing to a growing market demand. Experts estimate that UV coatings could account for over 20% of the total surface coating industry by 2010, signaling a major revolution in surface finishing technology.

UV Curing Technology in Mobile Phones: Key Applications

UV curing technology has become integral to mobile phone manufacturing, enhancing durability, appearance, and precision across various components:

- Phone Case Coatings – Special UV Varnish

UV curable varnishes are widely used for mobile phone cases. The rapid, low-temperature curing process prevents case deformation and reduces waste, producing a non-toxic, VOC-free finish that is also highly resistant to scratches. UV varnishes allow flexibility in gloss levels, from high gloss to matte, and can create a variety of surface effects for different phone models. Leading brands such as GOVE, Panstar, and Musashi have developed UV varnishes known for their exceptional gloss, depth, and texture. - Keyboard Wear-Resistant Ink

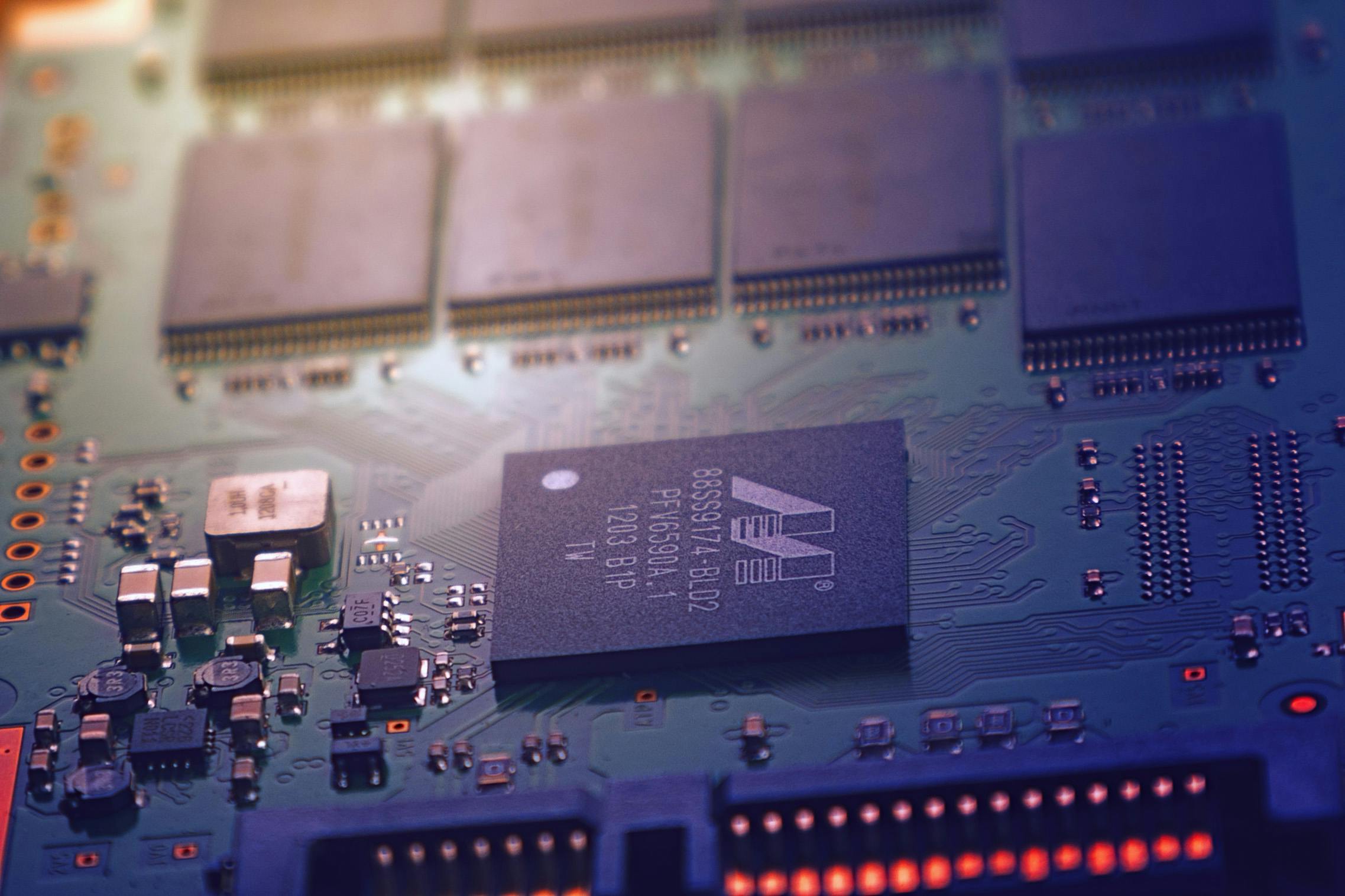

Mobile phone keyboards are some of the most heavily used parts of a device. UV curable wear-resistant character inks, often overlaid with a UV-protective varnish, add durability and prevent wear on keyboard lettering and symbols, especially for devices with extensive keypad use. - Circuit Board Protection – UV Electronic Protective Glue

Circuit boards are vital to mobile phone function and durability. Using UV electronic protective glue adds an extra layer of protection, making them waterproof, dustproof, and shockproof. This UV-cured layer helps prevent damage during soldering and ensures longevity for complex circuits. - LCD Screens – UV Glue

The sensitive nature of liquid crystal displays (LCDs) requires a curing process that doesn’t involve heat or contaminants. UV glue meets this requirement perfectly, as it instantly cures without heating and allows UV light to pass through the glass layers, protecting the integrity of the liquid crystal display.

In addition to mobile phone production, UV curing technology supports other communication industry applications, such as UV coatings for glass fiber filaments in communication cables and photoresists in semiconductor manufacturing.

The Future of Mobile Phone-Specific UV Coatings

With the increasing demand for high-performance, eco-friendly coatings in communication and electronics, specialized companies like Dove have emerged. Since 1999, Dove has focused on developing UV curing solutions for high-end fields, including multi-layer circuit board coatings, solder mask inks, and UV-protective adhesives. By collaborating with top universities and research institutes, Dove has developed leading UV technologies that meet global standards, making it a key supplier in the communications and electronics industries.

Conclusion: UV Curing Technology is Transforming Mobile Phone Manufacturing

The use of UV curing technology in mobile phone production offers unparalleled advantages in durability, efficiency, and environmental sustainability. From durable case coatings to intricate circuit board protection, UV curing technology has introduced a new era of surface coating innovations, providing mobile phone manufacturers with the tools to create reliable, eco-friendly products that meet consumer demands for style and longevity.

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt