RC800 Plasma Surface Modification System – A Stable Surface Treatment Solution

In modern industrial manufacturing, where higher demands are placed on durability, adhesion strength, and surface uniformity, plasma technology has become an inevitable trend. The RC800 Plasma Surface Modification System was developed to meet these stringent requirements, providing an efficient, precisely controlled, and automation-ready solution for surface treatment applications.

1. Introduction to the RC800 Plasma Surface Modification System

The RC800 Plasma Surface Modification System is a cold plasma-based solution designed for surface treatment and modification prior to processes such as adhesive bonding, coating, printing, or functional surface application. By generating a stable plasma jet, the system enables micro-level cleaning, surface activation, and a significant increase in surface energy.

Compared to traditional surface treatment methods such as chemical solvents or mechanical abrasion, the RC800 Plasma Surface Modification System operates at low temperatures, does not deform materials, produces no hazardous waste, and is environmentally friendly. As a result, it is particularly suitable for industries including electronics, engineering plastics, automotive, packaging, medical devices, and composite materials.

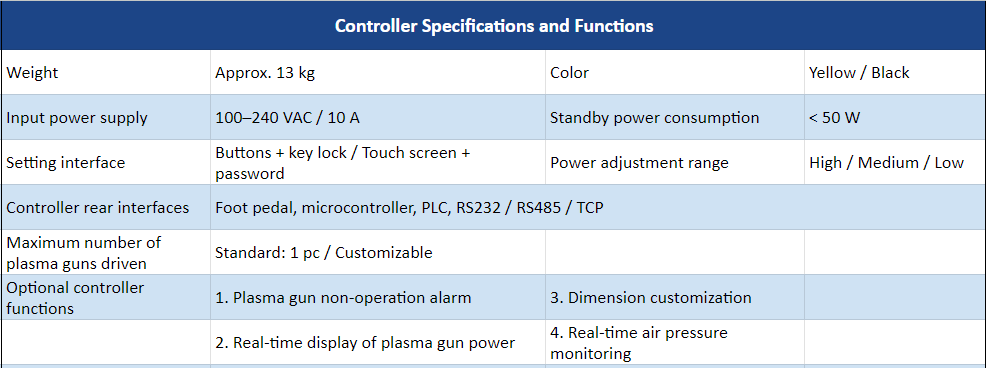

2. Technical Specifications of the RC800 Plasma Surface Modification System

The system is engineered with an optimized configuration for continuous industrial production, ensuring high operational stability and precision.

With its robust design and digital control architecture, the RC800 can operate reliably in demanding production environments while maintaining consistent treatment quality.

3. Key Features of the RC800 Plasma Surface Modification System

3.1. Smart and Precise Control

The RC800 is equipped with an intelligent control system that allows users to:

-

Digitally control gas pressure and plasma power

-

Configure advanced parameters for different material types

-

Ensure high repeatability across production batches

This level of precision helps maintain consistent surface treatment results throughout long-term operation.

3.2. Traceability and Data Monitoring Capabilities

-

Real-time display of gas pressure and power supply status

-

Continuous monitoring of component data

-

Instant recording of operating status to support quality control

These functions enable manufacturers to track process data, evaluate performance, and optimize production workflows.

3.3. Integrated Safety Warning System

The RC800 Plasma Surface Modification System includes a comprehensive safety alert mechanism:

-

Upper and lower threshold warnings for pressure and power

-

Component fault alerts

-

Reduced operational risks and minimized unplanned downtime

This ensures safer operation and greater equipment reliability.

3.4. Flexible Operating Modes

-

Supports both manual and automatic operation

-

Adjustable delay-time settings for different processes

-

Suitable for R&D testing as well as mass production

The flexibility of the RC800 allows it to adapt easily to various production scenarios.

3.5. User-Friendly Design

-

Intuitive touchscreen interface for easy operation

-

45° tilted panel for improved visibility

-

Simplified interface that reduces training time for operators

The ergonomic design improves usability and overall operational efficiency.

3.6. Information Management and System Integration

-

Optional IO / MES system integration

-

Instant upload of real-time equipment status

-

Fully compatible with smart factory and digital manufacturing trends

This makes the RC800 an ideal solution for Industry 4.0-oriented production lines.

4. Operating Notes for the RC800 Plasma Surface Modification System

To ensure stable performance and extended service life, users should observe the following guidelines:

-

Always operate the system in a well-ventilated environment

-

Avoid strong impacts during transportation and installation

-

Do not modify system configurations without technical guidance

5. Maintenance Guidelines for the RC800 Plasma Surface Modification System

Regular maintenance is essential to maintaining optimal performance:

-

Periodic cleaning every 6 months: Remove dust from cooling fans, high-voltage transformers, and internal components to ensure proper heat dissipation.

-

Plasma gun protection: Ceramic components inside the plasma gun require careful handling to avoid damage from impact.

-

Plasma electrode cleaning: After prolonged operation, oxidation and dust accumulation may occur; timely cleaning is necessary to maintain stable plasma output.

-

Proper gas hose disconnection: When removing the gas hose, press and hold the retaining ring on the connector before pulling the hose out to prevent connector damage and air leakage.

Conclusion

With intelligent control, comprehensive monitoring, and flexible operation, the RC800 Plasma Surface Modification System is an ideal choice for manufacturers seeking a modern, stable, and sustainable surface treatment solution. The system not only enhances product quality but also helps optimize operating costs and long-term production efficiency.

Contact for Consultation

👉 For detailed consultation on the RC800 Plasma Surface Modification System, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

RC800 Plasma Surface Modification System

RC800 Plasma Surface Modification System delivers precise, stable plasma surface treatment with smart control and easy automation integration.

Product SKU: ROTARY04E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-31

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com