Inline Plasma Surface Treatment Systems – A Surface Treatment Solution for Industrial Manufacturing

As industrial manufacturing increasingly demands high precision, stability, and strict quality control, Inline Plasma Surface Treatment Systems have emerged as an advanced technological solution that helps manufacturers improve adhesion quality, reduce product defects, and optimize surface treatment processes.

1. Overview of Inline Plasma Surface Treatment Systems

Jet nozzle plasma surface cleaner utilize low-temperature plasma technology to perform micro-cleaning and surface activation before processes such as adhesive bonding, coating, printing, or assembly.

This treatment process is chemical-free, non-abrasive, and does not cause material deformation.

The system is particularly suitable for electronics, engineering plastics, and industrial components—applications that require a high level of surface cleanliness and strong adhesion while ensuring safety for heat-sensitive materials.

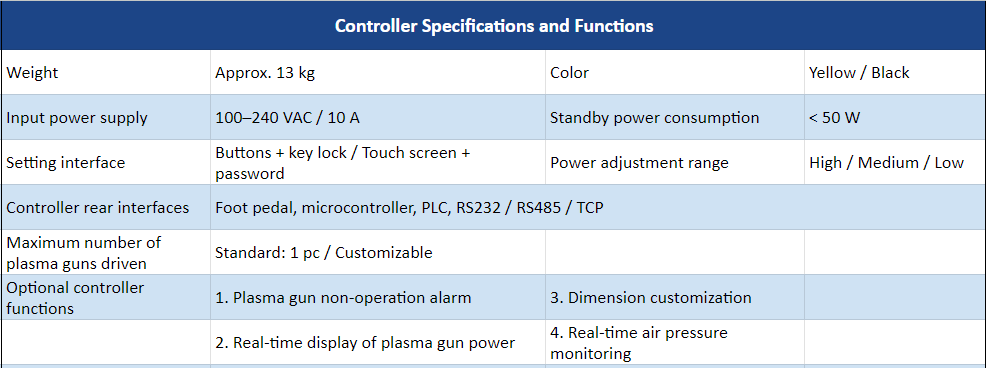

2. Technical Specifications of Inline Plasma Surface Treatment Systems

Understanding the technical specifications enables manufacturers to select the most suitable equipment for their production lines:

3. Key Advantages of Inline Plasma Surface Treatment Systems

Why should manufacturers invest in this system? Below are the outstanding advantages offered by jet nozzle plasma surface cleaner:

-

Enhanced adhesion performance

Plasma activates functional groups on material surfaces, allowing inks, adhesives, and coatings to bond more securely. -

Atomic-level surface cleaning

Effectively removes dust, oil, and microscopic organic contaminants invisible to the naked eye. -

Environmentally friendly process

Dry treatment technology with no hazardous chemicals and no liquid waste emissions. -

Material protection

Low-temperature (cold plasma) processing prevents deformation or alteration of the physical and chemical properties of plastics, metals, or glass.

4. Comparison Between Inline Plasma Surface Treatment Systems and Flame Treatment Technology

Many manufacturing facilities still rely on flame treatment. However, when compared with Inline Plasma Surface Treatment Systems, the differences are significant:

| Criteria | Flame Treatment Technology | Inline Plasma Surface Treatment Systems |

|---|---|---|

| Safety | High fire and explosion risk due to gas usage | Extremely safe, using electricity and compressed air |

| Consistency | Difficult temperature control, risk of surface burning | Uniform and precise treatment down to each millimeter |

| Material compatibility | Limited for heat-sensitive materials | Suitable for plastics, rubber, glass, and metals |

| Long-term effectiveness | Adhesion performance degrades quickly over time | Surface activation lasts significantly longer |

Why Choose jet nozzle plasma surface treatment machine from us?

Investing in plasma treatment machine is not just an upgrade in machinery—it is an upgrade in your final product quality.

We are committed to supplying genuine equipment, providing professional installation, and delivering comprehensive technology transfer to ensure optimal performance for your production line.

CONTACT US FOR CONSULTATION

To receive a detailed quotation and request a free sample test using plasma treatment equipment, please contact:

Inline Plasma Surface Treatment Systems

Inline Plasma Surface Treatment Systems enhance adhesion, improve surface cleanliness, and optimize quality control in industrial manufacturing.

Product SKU: JETPLASMA03E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-31

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com