Inline Plasma Cleaning Machine RC800

In modern manufacturing industries such as electronics, automotive, engineering plastics, and medical devices, surface cleanliness and activation requirements are becoming increasingly stringent. The Inline Plasma Cleaning Machine RC800 was developed as an advanced solution to help manufacturers optimize surface quality, enhance adhesion performance, and improve product stability throughout the production process.

1. Introduction to the Inline Plasma Cleaning Machine RC800

The Inline Plasma Cleaning Machine RC800 is a surface treatment system based on cold plasma technology, designed to effectively remove oils, dust, organic contaminants, and microscopic surface impurities. Unlike traditional chemical or mechanical cleaning methods, plasma treatment is a dry, environmentally friendly process that does not damage the material surface.

The RC800 is suitable for both standalone operation and integration into automated production lines, meeting the demands of continuous manufacturing with high stability and repeatability.

2. Specifications of the Inline Plasma Cleaning Machine RC800

2.1. Plasma Nozzle Specifications (Rotary Type)

Rotary Plasma Head Gun

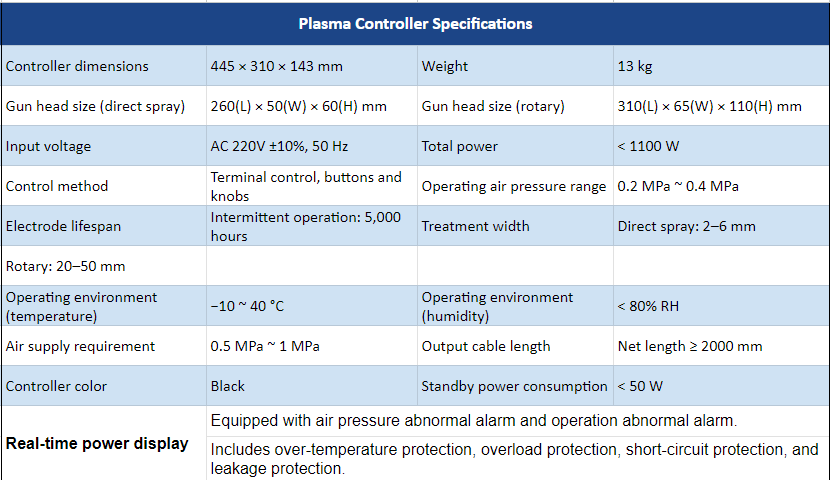

2.2. Controller Specifications

3. Key Advantages of the Inline Plasma Cleaning Machine RC800 (Rotary Nozzle Design)

One of the most outstanding advantages of the Inline Plasma Cleaning Machine RC800 is its rotary nozzle design.

Large nozzle treatment area (5 mm – 7 mm)

Compared to conventional direct plasma nozzles with a treatment width of only about 2 mm, the rotary nozzle of the RC800 provides a significantly wider plasma coverage area. This allows manufacturers to:

-

Achieve uniform cleaning on large surfaces

-

Reduce processing time

-

Increase overall production efficiency

Continuous rotary motion

The rotating nozzle ensures even plasma distribution, preventing uneven treatment or “dead zones” on the material surface.

Optimized for complex surfaces

The system is especially effective for components with curved shapes, deep grooves, or uneven surfaces.

Thanks to this advanced design, the Inline Plasma Cleaning Machine RC800 is highly valued in applications requiring high stability and excellent process repeatability.

4. Working Principle of the Inline Plasma Cleaning Machine RC800

The system uses a high-frequency power supply to excite process gases (compressed air, oxygen, or mixed gases) and generate cold plasma. The plasma stream contains highly active particles capable of:

-

Breaking molecular bonds of organic contaminants

-

Performing micro-level surface cleaning

-

Increasing surface energy and improving adhesion of adhesives, coatings, and printing inks

The process is fast, generates minimal heat, and does not deform or damage the material.

5. Product Warranty Policy

When investing in the Inline Plasma Cleaning Machine RC800, customers can be fully confident thanks to a clear and reliable warranty policy:

Warranty

-

Free warranty for the entire machine for 01 year

-

Lifetime technical support

Notes

-

Consumable parts are not covered under warranty

-

Electrodes and nozzles: recommended periodic maintenance every 3 months

This policy helps businesses minimize operational risks and optimize long-term ownership costs.

Conclusion

With its advanced rotary nozzle design, large treatment area, and stable cleaning performance, the Inline Plasma Cleaning Machine RC800 is an ideal solution for manufacturers seeking an efficient, durable, and environmentally friendly surface treatment technology.

👉 For detailed consultation, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

Inline plasma cleaning machine RC800

Inline plasma cleaning machine RC800 delivers efficient surface activation and stable performance for modern manufacturing industries.

Product SKU: ROTARY02E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-31

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com