CYM405 UV Glue Curing Machine – A Technology Platform for Advanced UV Curing

As industrial manufacturing increasingly demands higher precision, operational stability, and process control, UV curing technology has become an essential component across industries such as electronics, printing, medical devices, precision mechanics, and advanced materials.

The CYM405 UV Glue Curing Machine has been developed to meet these stringent requirements, delivering a flexible, stable, and multi-wavelength UV LED curing solution suitable for a wide range of modern production lines.

1. What is the CYM405 UV Glue Curing Machine?

The CYM405 UV Glue Curing Machine is an industrial UV curing system powered by high-performance UV LED technology, supporting four primary wavelengths: 365 nm, 385 nm, 395 nm, and 405 nm. These wavelengths represent the most commonly used and technically important ranges in current UV adhesive curing applications.

Unlike traditional single-wavelength UV curing equipment, the CYM405 allows manufacturers to select or combine multiple wavelengths, significantly improving compatibility with a wide variety of UV adhesives, UV inks, and UV coatings available on the market.

Thanks to its industrial-optimized design, the CYM405 UV Glue Curing Machine is suitable for both semi-automated production lines and highly automated manufacturing systems.

2. Operating Principle of the CYM405 UV Glue Curing Machine

The CYM405 UV Glue Curing Machine operates based on photopolymerization. When UV light irradiates UV adhesives or inks, photoinitiators within the material absorb the UV energy and trigger polymer cross-linking reactions. This process transforms the material from a liquid state into a solid state within a very short time.

The basic curing process includes:

- Emission of UV light at the appropriate wavelength

- UV energy absorption by photoinitiators in the adhesive

- Rapid and uniform polymerization reaction

- Achievement of the required surface strength and stability

With precise control over irradiation intensity and exposure time, the CYM405 UV Glue Curing Machine ensures consistent curing quality while minimizing under-curing or over-curing risks.

3. Four Key UV Wavelengths and Their Roles in UV Adhesive Curing

One of the core advantages of the CYM405 UV Glue Curing Machine is its support for four critical UV wavelengths:

365 nm wavelength

- The most widely used wavelength in UV adhesive curing

- High stability with strong penetration capability

- Suitable for most conventional UV adhesives and inks

385 nm wavelength

- Enhances curing performance for thicker adhesive layers

- Improves curing efficiency in lower layers

- Commonly used in electronics and precision mechanical applications

395 nm wavelength

- Reduces thermal impact on heat-sensitive surfaces

- Suitable for plastics, films, and thin materials

- Meets higher safety requirements

405 nm wavelength

- Softer UV light, more comfortable for working environments

- Highly compatible with next-generation UV adhesives

- Frequently used in medical and precision device applications

The flexible combination of these wavelengths allows the CYM405 UV Glue Curing Machine to adapt to diverse applications without requiring a complete system replacement.

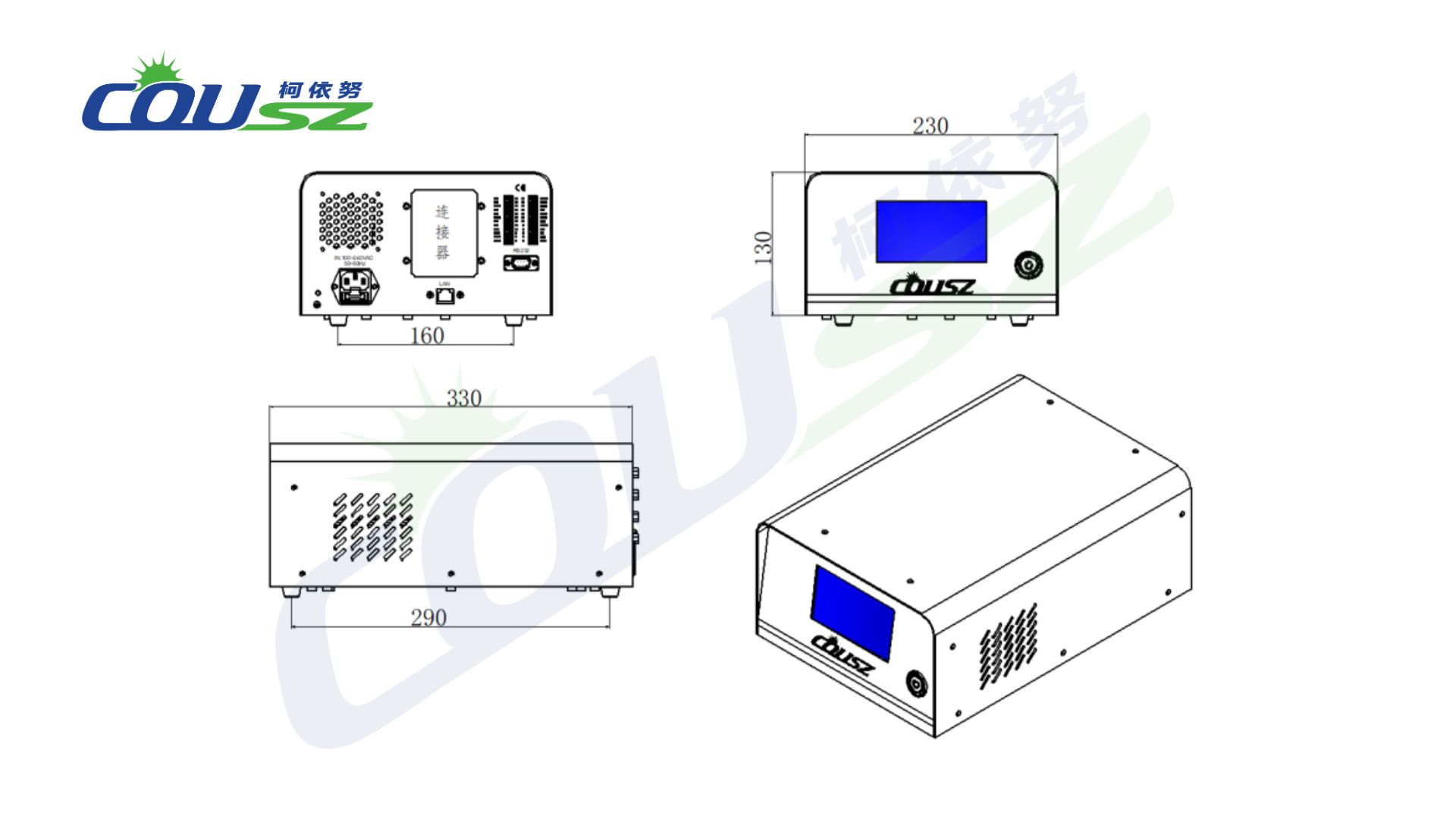

4. System Structure of the CYM405 UV Glue Curing Machine

The CYM405 UV Glue Curing Machine features a modular design that simplifies integration, maintenance, and future expansion:

- Multi-wavelength UV LED light source: stable output with high curing efficiency

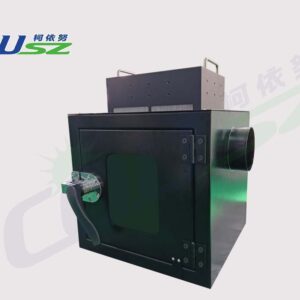

- Industrial UV lamp head: robust design resistant to vibration and harsh production environments

- Efficient cooling system: maintains stable operating temperature during continuous operation

- Signal interfaces: support integration with PLCs, robots, and conveyor systems

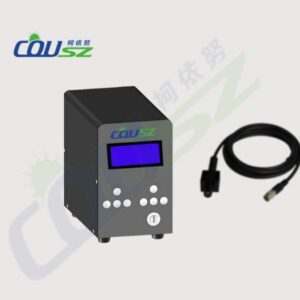

- UV curing controller M3

This structure enables the CYM405 UV Glue Curing Machine to meet the demanding requirements of modern industrial manufacturing.

5. Operating Lifetime and Maintenance Cycle

Compared to traditional mercury UV lamps, the UV LED source used in the CYM405 UV Glue Curing Machine offers a significantly longer service life:

- Average operating lifetime: 20,000 – 30,000 hours

- No frequent lamp replacement required

- Stable light output over long-term operation

Routine maintenance typically includes:

- Periodic inspection of the cooling system

- Cleaning of lamp heads and ventilation channels

- Inspection of electrical and signal connections

The simplified maintenance cycle helps reduce downtime and optimize long-term operating costs.

Contact for CYM405 UV Glue Curing Machine Consultation

Are you looking for a CYM405 UV Glue Curing Machine that fits your production line requirements?

👉 Contact COUSZ today for fast and professional consultation:

-

Contact person: Ms. Yuna

-

Hotline: +84 965 535 348

-

Email: sales03@cousz.com

UV Glue Curing Machine

The CYM405 UV Glue Curing Machine is a multi-wavelength UV LED curing solution designed for precise, stable, and efficient UV curing

Product SKU: COUSZCYM405E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Very reliable brand.

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com