The COUSZ LED-Type Customized UV Multi-Point Light Source Curing Equipment represents an advanced solution for UV curing applications. Utilizing high-efficiency energy conversion from electricity to light, it harnesses the precision of imported high-power ultraviolet diode chips to emit high-purity UV light across multiple wavelengths, including 365 nm, 385 nm, 395 nm, and 405 nm. With its highly concentrated energy output, this cutting-edge system serves as an ideal replacement for traditional fiber optic high-pressure mercury lamp point light source machines, meeting the specific wavelength requirements for UV adhesive curing and ink drying processes.

Product Features: Controller

Feature 1: Intuitive Operation Interface

- Offers a user-friendly English interface for quick and straightforward operation.

Feature 2: Independent Control of LED Optical Heads

- Supports independent control for 4-LED and 8-LED optical heads, with customization available for additional units.

- Allows individual adjustment of irradiation power, timing, and duration for each optical head.

Feature 3: Easy Installation

- Designed with a built-in power supply, achieving the industry’s smallest controller size.

- Eliminates the need for managing, purchasing, or replacing external power adapters.

Feature 4: Enhanced Safety and Stability

- Equipped with a signal control terminal of Japanese origin, the same model used by Panasonic, ensuring reliable performance.

Feature 5: External Control and Signal Output

- Facilitates automated production line integration through external input signals for UV control.

- Compatible with external devices such as programmable controllers to manage UV irradiation duration in 0.1-second increments.

- Provides alarm signals for abnormalities in LED optical heads and outputs operational status signals, streamlining automation processes.

Feature 6: Temperature Feedback for Constant Illumination

- Ensures irradiation accuracy within ±3% at 80% output.

- Incorporates a high-efficiency metal heat sink and built-in temperature sensors in the optical heads to maintain stability.

- Achieves consistent UV output despite temperature fluctuations, ideal for precise and high-quality bonding applications.

Feature 7: Foolproof Settings

- Includes a locking feature for setting parameters and controller operations.

- Prevents accidental interruptions during irradiation and ensures adequate exposure.

Feature 8: Step Irradiation Function

- Minimizes deformation during hardening to achieve superior bonding precision.

- Offers a range of step and pulse modes to optimize hardening processes.

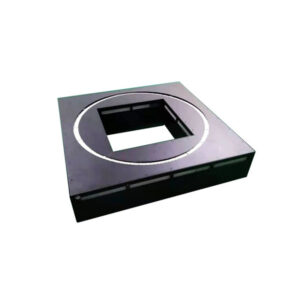

Feature 9: Durable All-Aluminum Enclosure

- Features a closed, all-aluminum design to prevent dust accumulation and resist rust over extended periods.

Feature 10: LED Life Recording

- Monitors and records the operating time of each LED optical head.

- Alerts users to replacement periods based on cumulative usage or abnormal temperature warnings.

This controller is engineered for precision, reliability, and seamless integration into high-performance UV curing systems, making it an ideal choice for demanding industrial applications.

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.