COUSZ UV Curing Machine – Advanced UV Curing Solution

In the era of Industry 4.0, drying technology has reached a new level. The UV area curing machine is no longer just a piece of equipment—it is a key solution that ensures both speed and quality across various manufacturing industries. This article provides an in-depth overview of the working principle, structure, applications, and essential knowledge to help you master modern UV curing technology.

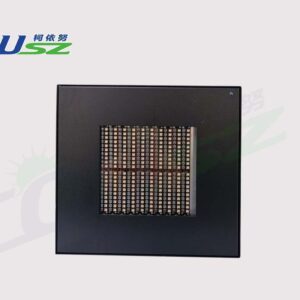

1. What is the COUSZ UV Curing Machine?

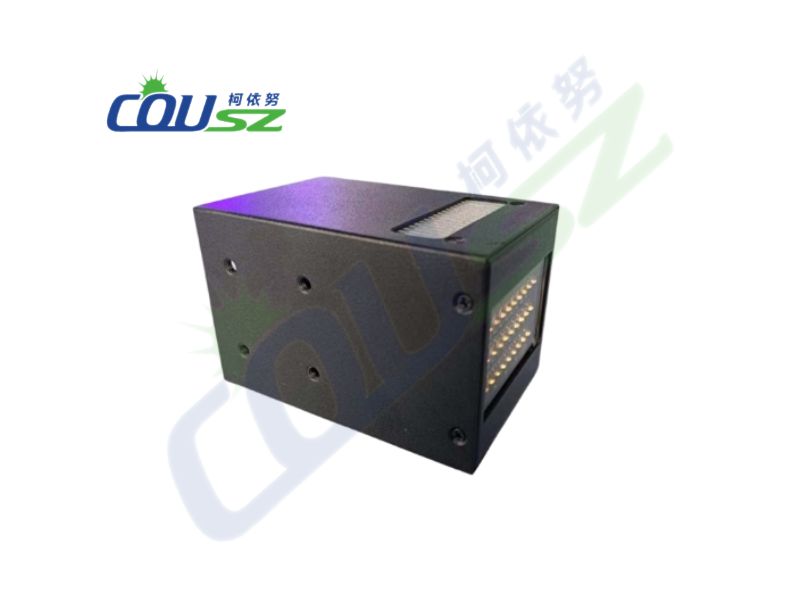

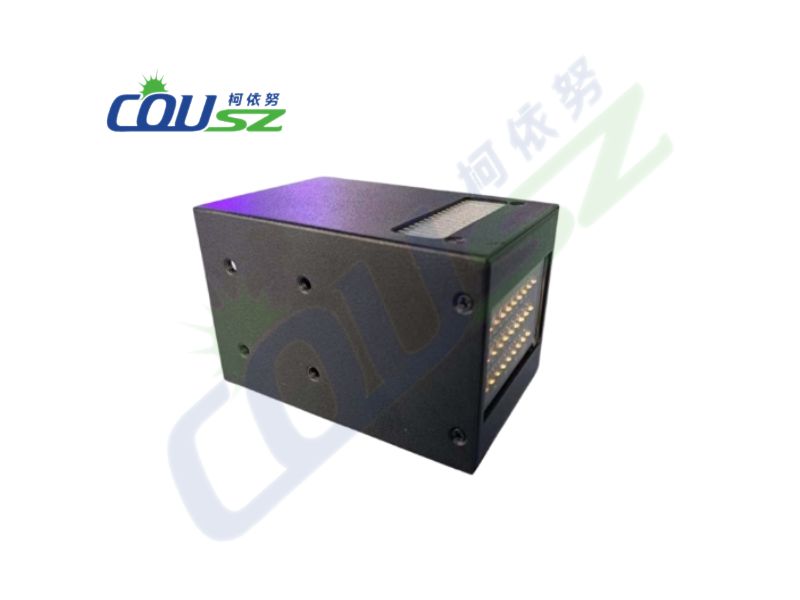

The COUSZ UV Curing Machine (Area Curing Systems) is an industrial device that uses ultraviolet (UV) light to dry or cure UV-sensitive materials such as printing inks, adhesives, coatings, and paints. When exposed to UV radiation, a photochemical reaction occurs, causing the material to transform from a liquid state into a solid almost instantly.

The key advantage of UV area curing technology lies in its curing speed, which is significantly faster than traditional thermal drying methods. As a result, it helps reduce production time, increase productivity, and lower operating costs.

This technology is widely applied in industries such as printing, electronics manufacturing, packaging, plastics, automotive, woodworking, and medical equipment production.

2. Working Principle of the COUSZ UV Curing Machine

The COUSZ UV Curing Machine operates based on a photopolymerization reaction. When UV light irradiates the material surface, the energy from ultraviolet rays activates chemical molecules within the ink or adhesive, triggering a rapid reaction that cures the material within seconds.

The system typically consists of high-power UV lamps, a reflector system to concentrate light, a conveyor mechanism, and an electronic control unit. As the material passes through the UV exposure zone, the concentrated UV beam ensures uniform and durable curing.

Key advantages of this mechanism include:

-

No need for high temperatures, preventing material deformation

-

Extremely fast curing speed, boosting productivity

-

Lower energy consumption compared to thermal drying systems

-

Environmentally friendly, with no harmful emissions

3. Technical Specifications of the COUSZ UV Curing Machine

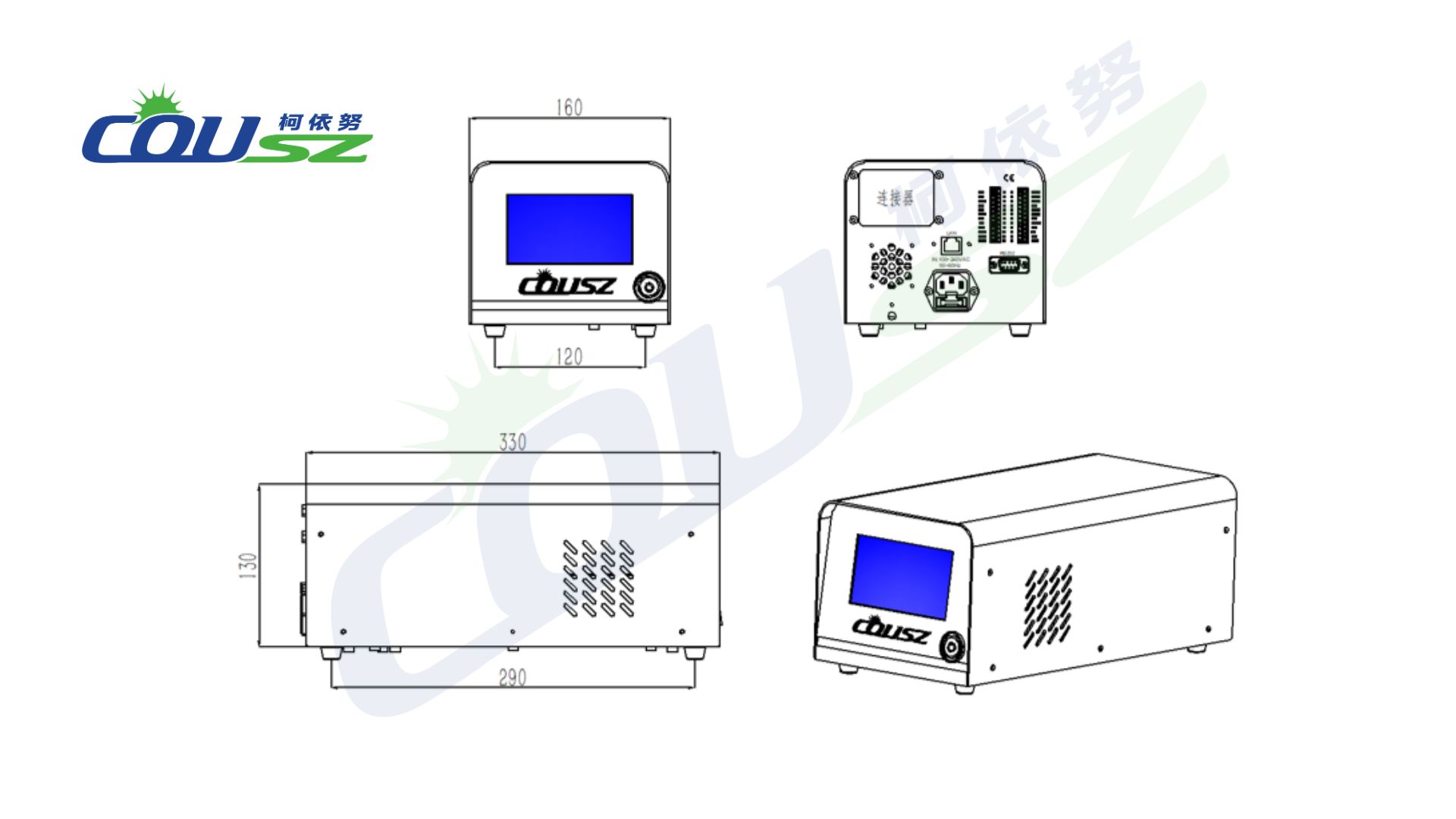

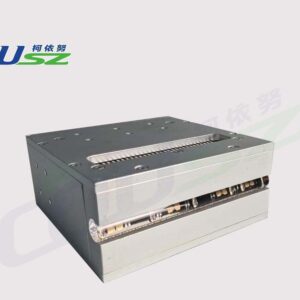

POWER SUPPLY

| Specification | Details | Specification | Details |

|---|---|---|---|

| Dimensions (mm) | L330 × W160 × H130 | Power | 50W |

| Cooling | Fan cooling | Input voltage | 100–240V AC 50~60Hz |

| Weight / Material | Approx. 3.5 kg, Metal | Output power | 10%–100% |

| Setting lock | Password-protected advanced settings | Display & control | Touchscreen; time, intensity |

| LED light sources | 1–4 units | Control | Foot pedal, SCM, PLC, RS232/RS485/TCP |

| Alarm | Over-temperature, system fault alerts | Operating time | Cumulative usage time recording |

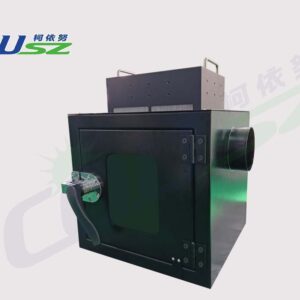

LIGHT SOURCE

| Specification | Details | Specification | Details |

|---|---|---|---|

| Light-emitting area (mm) | 30 × 50 | Dimensions (mm) | L100 × W120 × H120 (adjustable) |

| Cooling | Fan cooling | LED lifespan | >20,000 hours |

| Weight / Material | Approx. 3 kg, Metal / Aluminum | Wavelength (nm) | 365 / 385 / 395 / 405 |

| Intensity (mW/cm²) | Adjustable | Monitoring | Intensity, temperature, etc. |

| Connection cable | 2–5 m (customizable) | Applications | Ink curing (especially inkjet), adhesive curing (CCM, VCM), inspection, etc. |

COUSZ UV Curing Machine

4. Applications of the COUSZ UV Curing Machine

Printing and Packaging Industry

UV curing enhances ink adhesion and color durability while enabling glossy or matte finishes as required. Typical applications include curing UV inks for labels, paper packaging, product boxes, and high-end catalogs, delivering superior aesthetics and durability compared to conventional thermal drying.

Electronics Industry

In electronics manufacturing, UV curing is used for bonding components, coating PCB surfaces, and encapsulating electronic chips. This method ensures strong adhesion, dust resistance, and moisture protection without thermal deformation, making it ideal for automated production lines.

Automotive Industry

UV curing is applied to coatings on plastic parts, interior components, and metal surfaces, improving gloss, scratch resistance, and UV resistance. It also shortens curing time, reduces energy consumption, and enhances surface quality.

Woodworking and Interior Decoration

UV curing technology is widely used to cure UV coatings on wood surfaces, plywood, flooring, and furniture, providing high gloss, color stability, and moisture resistance. It is an optimal solution for increasing both aesthetic value and product lifespan.

Medical and Pharmaceutical Industry

In this field, UV curing is used to dry and cure pharmaceutical packaging, syringes, vial caps, and medical materials that require sterilization. It ensures hygiene, surface durability, and compliance with strict medical standards.

5. Conclusion

The COUSZ UV Curing Machine is a modern solution that optimizes production processes, saves energy, and enhances product quality. From printing and electronics to woodworking and healthcare, UV curing technology plays a crucial role in the development of green and sustainable industrial manufacturing.

👉 Contact us today for free technical consultation and competitive quotations on COUSZ UV curing solutions.

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

COUSZ UV Curing Machine

Discover the COUSZ UV Curing Machine, its working principle, specifications, and applications across printing, electronics, and industry.

Product SKU: M3050E

Product Brand: COUSZ

Product Currency: VND

Product Price: 6868

Price Valid Until: 2025-12-31

Product In-Stock: InStock

5

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

👉 Contact Ms. Yuna for detailed technical consultation and to select the most suitable configuration for your production needs.

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com