COUSZ UV Chamber – Professional UV Curing Solution

In modern manufacturing industries, requirements for curing speed, process stability, and finished product quality are becoming increasingly demanding. COUSZ UV Chamber is developed to meet these strict standards, providing a safe, efficient, and versatile UV curing solution for a wide range of industrial applications.

1. Introduction to COUSZ UV Chamber

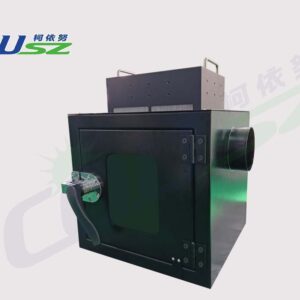

COUSZ UV Chamber is an enclosed UV curing system that uses high-quality UV lamps or UV LED light sources to rapidly dry and cure UV adhesives, inks, and coatings. Designed specifically for industrial production environments, the system ensures high stability and supports continuous operation.

Compared with conventional drying methods, UV chamber curing significantly reduces processing time, improves accuracy, and minimizes product defects. As a result, UV Chamber is widely used in electronics, precision mechanics, medical devices, packaging, printing, and energy-related industries.

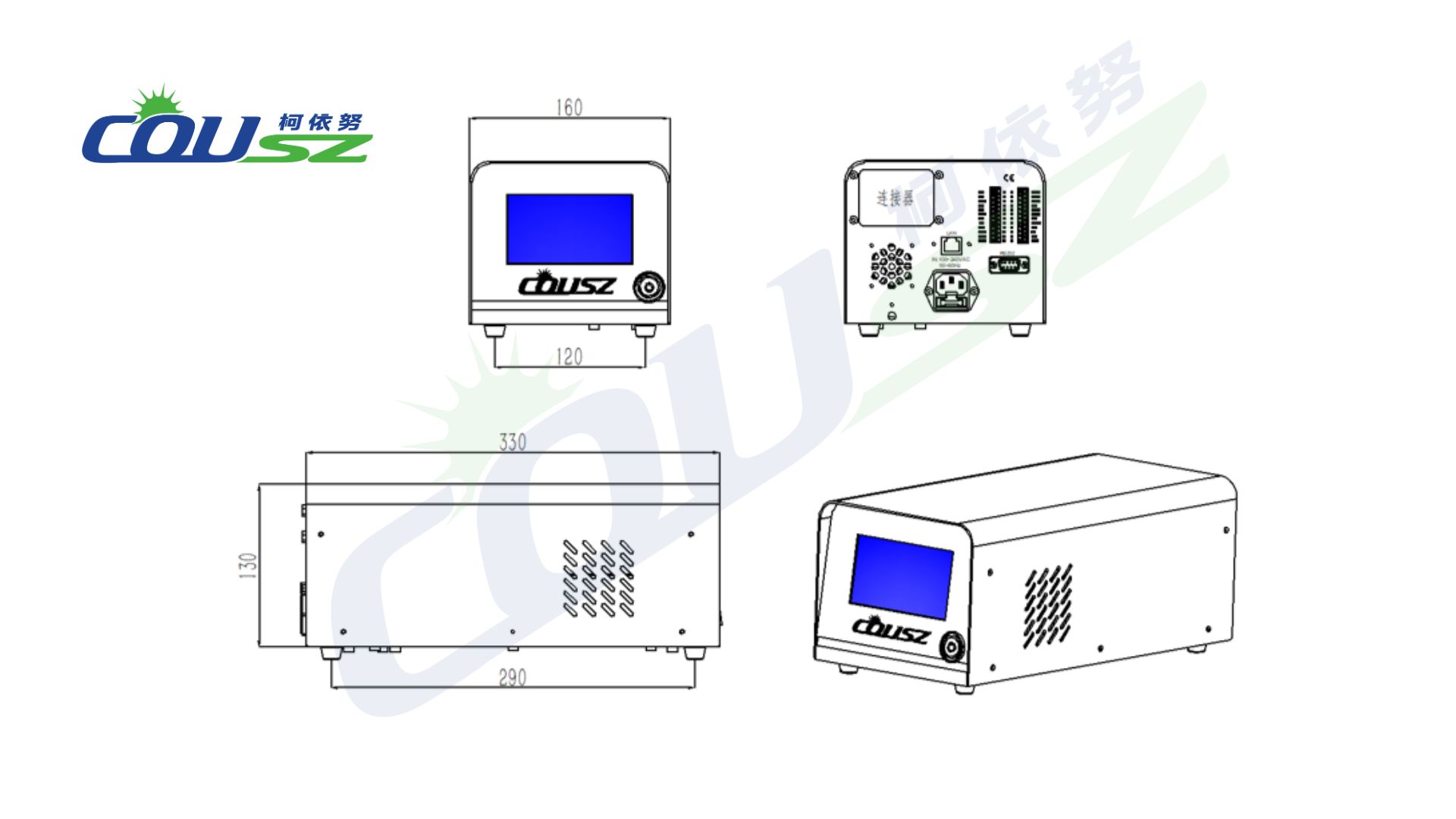

2. Technical Specifications of COUSZ UV Chamber

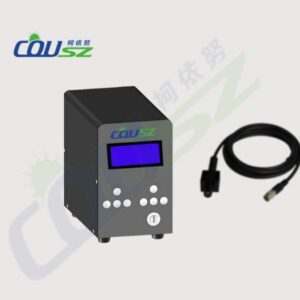

Controller

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Dimensions (mm) | Depends on light source | Material / Color | Sheet metal / Black |

| Input power | 100–240V AC, 50–60Hz | Standby power consumption | <50W |

| Weight | 1kg / 5kg / 10kg | ||

| Power adjustment range | 10–100% | ||

| Setting interface | Touch screen + password | Controller back-end ports | Foot pedal, MCU, PLC, RS232 / RS485 / TCP |

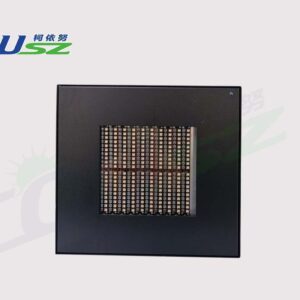

Light Source

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Irradiation area | 100×100 / 150×150 / 100×150 / 300×300 (customizable) | Power requirements | 100–240V AC, 50/60Hz |

| Cable length | 2m, 5m | Connector | 15-pin connector |

| Light source type | High-power imported UV LED | Time setting | 0.1–999.99 seconds |

| Output wavelength | UV365, 395, 405, 450, 470 (±10nm) | Control mode | Automatic or manual |

| Light intensity adjustment | 0–100% | Illumination distance | Depends on luminous area |

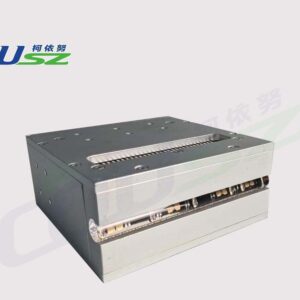

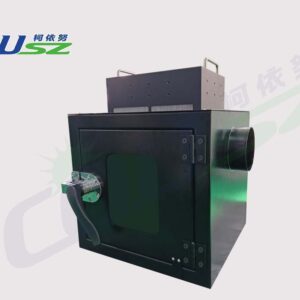

Oven (Chamber)

| Parameter | Value |

|---|---|

| Outer dimensions | L360 × W360 × H350 mm |

| Inner dimensions | L300 × W300 × H300 mm |

| Material / Weight | Sheet metal / 10 kg |

3. Working Principle of COUSZ UV Chamber

The operating principle of UV Chamber is based on a photochemical reaction:

-

Products are placed inside the UV chamber

-

UV lamps emit light at suitable wavelengths

-

UV adhesives or coatings absorb UV energy

-

Rapid curing and cross-linking reactions occur

-

The material surface achieves optimal dryness and adhesion

This process is completed in a very short time without high temperatures, helping protect sensitive materials and reduce energy consumption.

4. Key Advantages of UV Chamber

-

Fast and uniform UV curing, reducing product defects

-

Stable operation, ideal for continuous production

-

Lower energy consumption compared to thermal drying

-

Safe and environmentally friendly process

-

Easy operation, maintenance, and system upgrades

These advantages help manufacturers optimize operating costs while improving overall product quality.

With its modern design, high efficiency, and proven reliability, COUSZ UV Chamber is an ideal choice for companies seeking a professional and sustainable UV curing solution.

👉 Contact Ms. Yuna today for detailed technical consultation and to select the most suitable COUSZ UV Chamber configuration for your production line.

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

COUSZ UV Chamber

COUSZ UV Chamber delivers fast, stable, and energy-efficient UV curing for adhesives, inks, and coatings across industrial applications.

Product SKU: OVEN01E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2026-01-14

Product In-Stock: InStock

5

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

👉 Contact Ms. Yuna for detailed technical consultation and to select the most suitable configuration for your production needs.

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com