365nm UV Light Curing Conveyor – An Advanced UV Curing Solution for Modern Production Lines

In the era of modern industrial manufacturing—where automation, quality control, and process stability are top priorities—the 365nm UV Light Curing Conveyor has become a strategic choice for many factories. Beyond enabling continuous UV adhesive curing, this system integrates seamlessly into automated production lines, supports data monitoring, and ensures safe operation in demanding industrial environments.

1. Overview of the 365nm UV Light Curing Conveyor

The 365nm UV Light Curing Conveyor is a UV curing solution that uses a 365 nm UV LED light source combined with a conveyor system, allowing products to move continuously through the UV irradiation zone. The curing of UV adhesives, inks, or coatings is synchronized with production takt time, helping manufacturers optimize throughput while reducing reliance on manual handling.

Compared with standalone UV curing units or spot-curing methods, conveyor-based systems offer significantly higher stability and consistency. As a result, the 365nm UV Curing Conveyor is especially suitable for:

-

Electronics and precision components

-

High-accuracy assembly processes

-

Mass production requiring high repeatability

This makes the system an ideal choice for production lines undergoing standardization or upgrading toward semi-automated and fully automated manufacturing.

2. Structure of the 365nm UV Light Curing Conveyor

Designed for continuous operation in factory environments, the 365nm UV Curing Conveyor adopts a modular structure that is easy to integrate, customize, and expand.

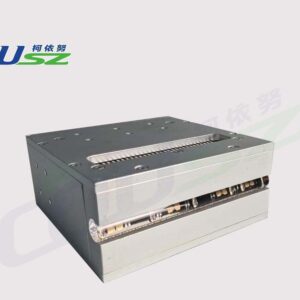

High-Performance Conveyor System

The conveyor is the core component that directly determines curing stability:

-

Continuous operation with flexible speed adjustment

-

High load-bearing capacity for various product types

-

Smooth motion that minimizes vibration and ensures curing quality

Thanks to this high-performance conveyor system, the 365nm UV Curing Conveyor delivers uniform curing results even during high-volume production.

365nm UV Light Source System

The 365 nm UV LED light source is widely recognized for its strong penetration capability, making it compatible with many conventional UV adhesives. This wavelength helps:

-

Ensure stable curing performance

-

Reduce the risk of incomplete or uneven curing

-

Support materials requiring deeper UV penetration

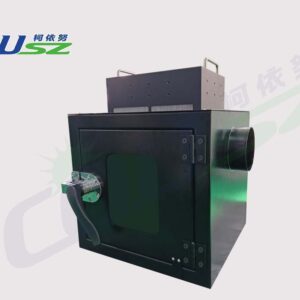

Enclosed UV Curing Chamber

The curing chamber is fully enclosed to:

-

Concentrate UV energy within the curing zone

-

Minimize energy loss

-

Prevent UV leakage into the surrounding environment

This design enhances curing efficiency while ensuring operator safety.

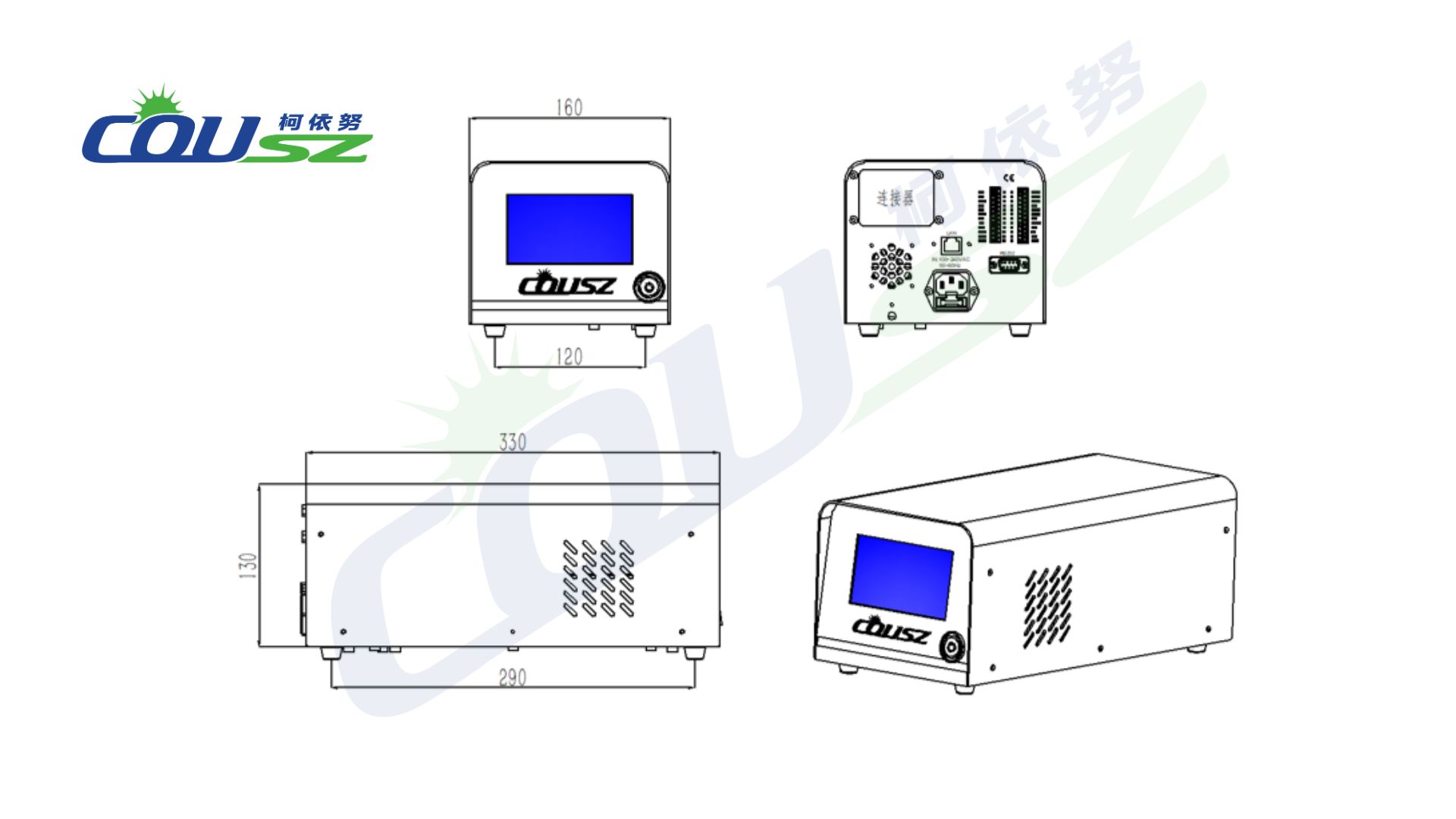

UV Curing Machine Controller

3. Intelligent Control and Connectivity Features

Flexible I/O Control and Signal Feedback

The 365nm UV Cure Conveyor is equipped with multiple flexible I/O interfaces, enabling:

-

Bidirectional communication with peripheral devices

-

Real-time status signal feedback

-

Seamless synchronization with centralized line control systems

This functionality is particularly valuable in factories using PLC-based or centralized control architectures.

Smart Network Connectivity with Open Standards

The system supports industrial network connectivity via:

-

TCP/IP communication ports

-

MODBUS protocol

Through these interfaces, the 365nm UV Light Cure Conveyor can be directly connected to MES (Manufacturing Execution Systems), enabling:

-

Real-time operational monitoring

-

Centralized production data collection

-

Process traceability and optimization

These capabilities support the transition toward smart manufacturing and Industry 4.0 environments.

4. Multiple Cooling Options: Water, Fan, and Air Cooling

To ensure stable UV output and extend LED lifespan, the 365nm UV Light Curing Conveyor offers multiple cooling solutions:

-

Fan cooling for standard configurations

-

Forced air cooling for enhanced heat dissipation

-

Water cooling for high-power or continuous-duty applications

This flexibility allows the system to adapt effectively to different production conditions and operating requirements.

5. Why Choose the 365nm UV Light Curing Conveyor?

-

Stable, continuous UV curing for mass production

-

Easy integration into automated production lines

-

MES-ready connectivity for smart factories

-

Enhanced safety for operators

-

Scalable design for future expansion

These advantages make the 365nm UV Light Curing Conveyor a long-term solution for manufacturers focused on efficiency, reliability, and sustainable growth.

Consultation for the 365nm UV Light Curing Conveyor

Selecting the right 365nm UV Light Curing Conveyor should be based on your actual production conditions, UV adhesive characteristics, and automation goals.

👉 For professional consultation and customized system configuration, please contact:

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

365nm UV Light Curing Conveyor

The 365nm UV Light Curing Conveyor delivers stable, continuous UV curing with smart connectivity, ideal for automated production lines.

Product SKU: COUSZCVC008E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2025-12-27

Product In-Stock: InStock

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

John –

Smooth service from start to end

admin –

Contact now for technical support!

Ms Yuna

📞 Hotline: +84 965 535 348

✉️ Email: sales03@cousz.com