What are UV meters and why are they essential in UV curing systems?

UV meters are essential tools for accurately measuring UV intensity and energy, ensuring adhesives, inks, and coatings are cured consistently and reliably. This article helps you understand how UV meters work, their applications, and how to choose the right UV meters for production.

1. What are UV meters?

UV meters are specialized optical instruments designed to measure the technical parameters of ultraviolet (UV) light. Each device consists of a UV-sensitive photodetector and a processing unit that displays measurement results.

In manufacturing and research, UV meters—also known as UV light meters—ensure processes remain within optimal limits. If UV intensity is too low, curing will be incomplete and cause defects. If it is too high, materials may be damaged and energy wasted.

The difference between qualified products and defective ones often lies in precise UV energy control. Using UV meters helps standardize processes, reduce errors, and optimize operating costs.

2. Key parameters measured by UV meters

When using UV meters, two core parameters define UV performance:

2.1. UV irradiance

Unit: mW/cm²

Meaning: Indicates the UV power delivered to a unit area at a given moment.

Application: Used to check lamp uniformity and stability during operation.

2.2. UV energy (energy density / dose)

Unit: mJ/cm²

Meaning: The total UV energy received over exposure time.

Application: Determines whether UV adhesives, inks, or coatings receive sufficient energy for complete curing.

Formula:

UV energy (mJ/cm²) = UV intensity (mW/cm²) × exposure time (s)

3. Classification of UV meters by wavelength range

Different applications require different UV wavelengths, so UV meters are designed for specific ranges:

3.1. UV-A meters (315–400 nm)

Commonly used in industrial UV curing

Suitable for UV LED 365 nm and 395 nm applications

3.2. UV-B meters (280–315 nm)

Used in medical treatments and material aging tests

3.3. UV-C meters (100–280 nm)

Designed for germicidal UV, typically 254 nm

Used in water, air, and surface disinfection systems

4. How to choose the right UV meters

4.1. Spectral response compatibility

Choose UV meters that match the wavelength of your UV source.

4.2. Measurement range

Ensure the UV meters support intensities equal to or higher than your lamp output.

4.3. Calibration certificate

UV meters should include a calibration certificate compliant with international standards such as NIST.

5. Benefits of investing in high-quality UV meters

Consistent production quality

Extended UV lamp lifespan

Reduced adhesive and coating waste

Optimized conveyor speed

Improved workplace safety compliance

6. Featured UV meters available at COUSZ

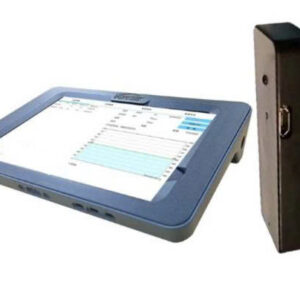

EIT UV meters

UV LED meters

F150 UV light meter

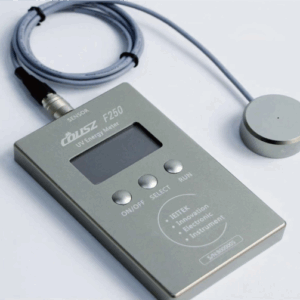

F250 UV measurement device

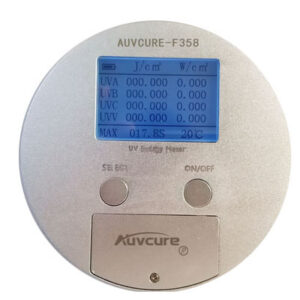

F358 UV radiometer

F460 UV light intensity meter

F480 UV intensity meter

F580 UV meter calibration service

COUSZ UV-A meter

UV-A & UV-C measurement devices

UV energy meter

UV-A & UV-C energy measurement devices

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt