1. What Is a UV LED Curing Machine?

A UV curing machine is a device that uses ultraviolet (UV) light to quickly dry or cure materials. The UV LED curing machine is an advanced version that utilizes LED UV lamps, offering better energy efficiency and a longer lifespan compared to traditional UV mercury lamps.

2. How Does a UV LED Curing Machine Work?

-

Traditional UV curing machines use mercury lamps to emit UV light, which reacts with ink, coatings, or adhesives to cure them.

-

UV LED curing machines use LED UV light with specific wavelengths to speed up the curing process without generating excessive heat, resulting in lower energy consumption.

3. Key Advantages of UV LED Curing Machines

-

Fast curing: Takes only a few seconds to complete the process.

-

Energy saving: Consumes less electricity and requires no warm-up time.

-

Low heat emission: Protects heat-sensitive materials during the curing process.

-

Environmentally friendly: No harmful gas emissions or ozone production.

-

Long lifespan: UV LED lamps last up to 20,000–30,000 hours—significantly longer than mercury lamps.

4. Applications of UV LED Curing Machines

4.1. Printing Industry

Cures UV ink on paper, plastic, and metal surfaces instantly, preventing smudging and improving print quality.

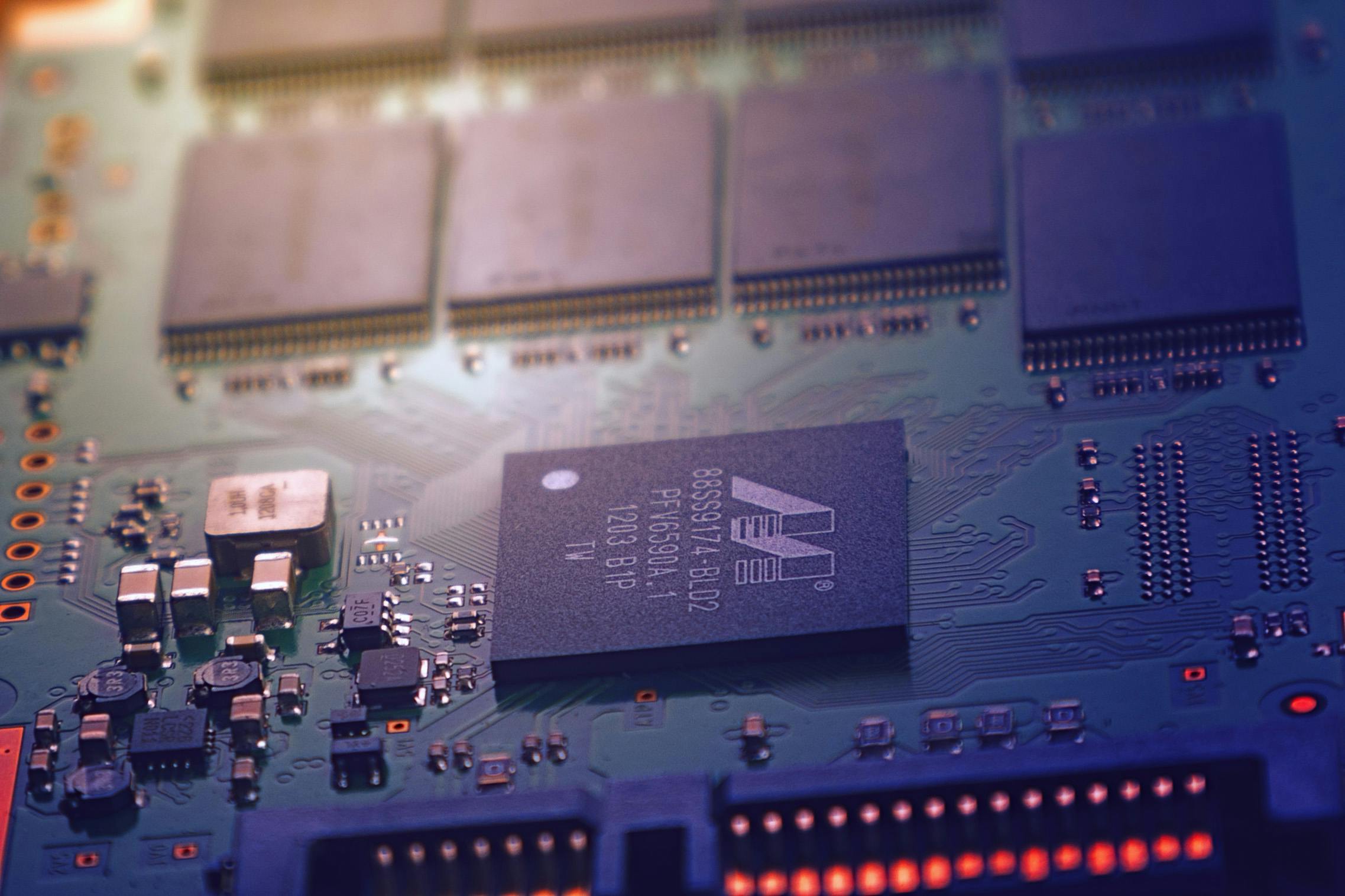

4.2. Electronics Manufacturing

Used in the bonding and protection processes of microcircuits, such as securing components or curing adhesives in camera modules and PCBs.

4.3. Medical Industry

Rapidly cures coatings on medical tools without damaging materials, ensuring hygiene and material integrity.

4.4. Wood & Plastic Processing

Cures UV coatings and protective finishes, enhancing surface gloss and long-term durability of wood and plastic products.

5. How to Choose the Right UV LED Curing Machine

-

Based on power requirements: High-power machines are ideal for mass production; low-power models suit small-scale or custom applications.

-

Based on UV lamp type:

-

UV LED curing machines: Energy-efficient, low heat emission, suitable for modern industrial upgrades.

-

Traditional UV curing machines: Lower initial cost, but shorter lamp lifespan and higher energy usage.

-

-

Brand and supplier: Choose reputable manufacturers or suppliers to ensure product quality and reliable warranty support.

6. How to Use and Maintain a UV LED Curing Machine

Operation:

-

Set the appropriate parameters for the material being processed.

-

Follow safety guidelines to avoid direct exposure to UV light.

Maintenance:

-

UV LED curing machines: Regularly check LED lamp lifespan and intensity.

-

Traditional UV curing machines: Replace mercury lamps once their lifespan ends.

-

Clean cooling fans and conveyor systems periodically to maintain stable performance.

7. Conclusion

UV LED curing machines offer a fast, energy-efficient, and eco-friendly solution for various industries. If you’re looking for a reliable, high-performance UV curing system, contact us today for expert consultation and customized solutions!

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt