In modern industrial manufacturing, where higher demands are placed on speed, precision, and automation, the COUSZ UV Cabinet has been developed as an advanced UV curing solution that delivers high performance, stability, and seamless system integration. Designed specifically for factory environments, the COUSZ UV Cabinet helps businesses improve product quality, reduce defects, and optimize operating costs.

1. Introduction to the COUSZ UV Cabinet

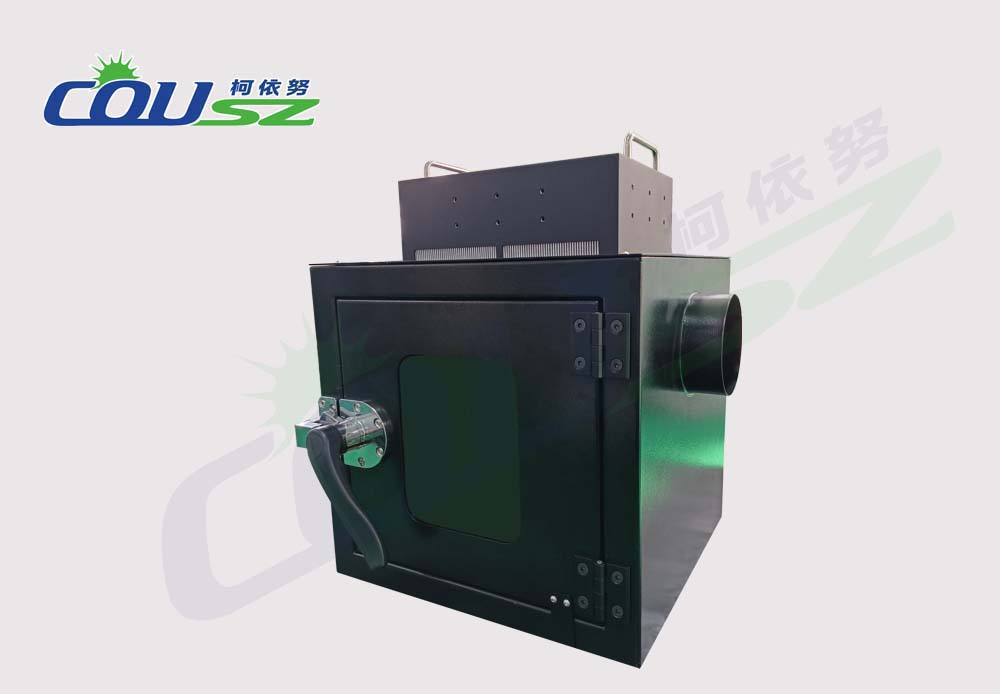

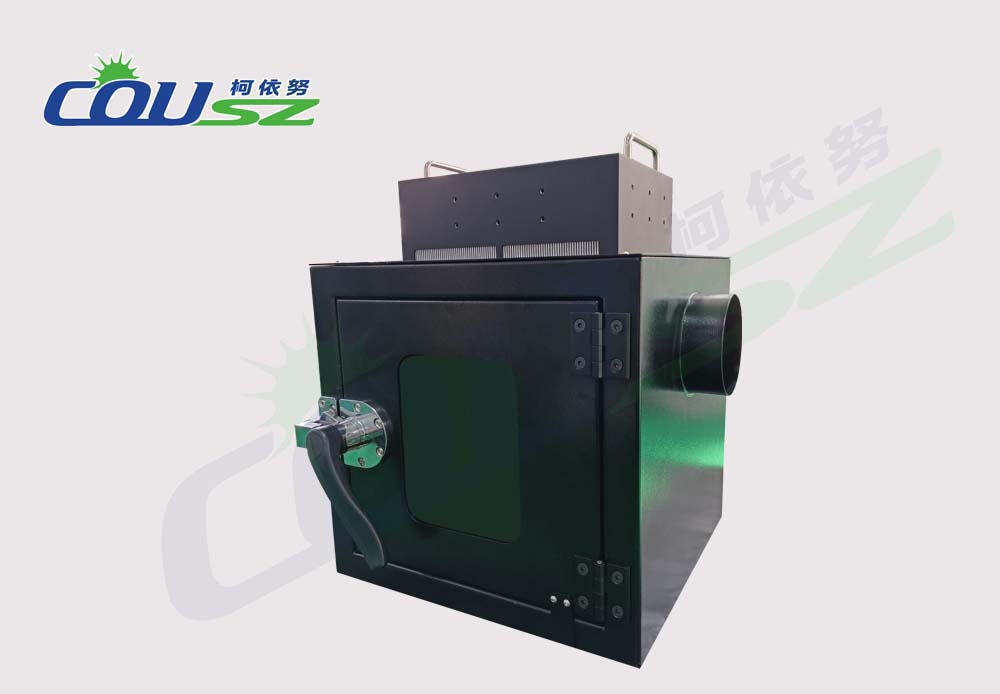

The COUSZ UV Cabinet is a closed-chamber UV curing system that uses high-power UV lamps or UV LED light sources to rapidly dry and cure UV adhesives, UV inks, and specialty coatings. The system is purpose-built for industrial production lines, ensuring high stability and reliable continuous operation.

Compared with conventional thermal drying methods, the COUSZ UV Cabinet significantly shortens processing time, minimizes material deformation, and ensures uniform adhesion quality. As a result, it is widely applied in electronics, printing, packaging, medical devices, precision engineering, and energy-related industries.

2. Operating principle of the COUSZ UV Cabinet

The operating principle of the COUSZ UV Cabinet is based on the photochemical reaction of UV-sensitive materials:

-

Products are placed inside the UV curing chamber

-

The UV light source emits radiation at suitable wavelengths

-

UV adhesives or coatings absorb UV energy

-

The curing reaction occurs almost instantly

-

The surface achieves optimal dryness, hardness, and adhesion

The curing process takes place at low temperatures, protecting heat-sensitive materials while reducing overall energy consumption.

3. Key features of the COUSZ UV Cabinet

3.1. Touchscreen light source parameter settings

All UV light source parameters can be configured directly via the touchscreen interface, enabling fast operation, high accuracy, and easy process control.

3.2. Independent multi-channel drive control

The COUSZ UV Cabinet supports independent multi-channel drive control, allowing each channel to be adjusted separately, with configurable lamp on/off delay settings to suit different production processes.

3.3. Multiple I/O interfaces

The system provides a wide range of I/O interfaces for signal control and feedback, making it easy to integrate with existing automation systems.

3.4. TCP/IP networking and MES integration

The COUSZ UV Cabinet is equipped with a TCP/IP communication port and supports the MODBUS protocol, enabling direct data connectivity with MES systems for smart production monitoring and management.

3.5. Comprehensive alarm and protection system

The machine integrates multiple alarm and protection functions, including:

-

Lamp head temperature monitoring

-

Short-circuit and open-circuit detection

-

Abnormal power output alerts

-

Light source lifetime degradation warnings

In addition, fail-safe and power-loss protection mechanisms ensure maximum safety for both equipment and products.

3.6. Online UV intensity monitoring

The COUSZ UV Cabinet features an integrated online UV intensity meter, enabling adaptive control of light source power and ensuring consistent curing performance.

3.7. Multiple communication standards

The system fully supports RS232, RS485, and TCP/IP communication interfaces and complies with the MODBUS protocol, facilitating system expansion and flexible connectivity.

Consultation & Contact

👉 Contact Ms. Yuna today for detailed technical consultation and to select the most suitable COUSZ UV Cabinet configuration for your production line.

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com

COUSZ UV Cabinet

COUSZ UV Cabinet delivers fast, stable UV curing with smart control, MES connectivity, and energy-efficient operation for industry.

Product SKU: OVEN01E

Product Brand: COUSZ

Product Currency: VND

Product Price: 8888

Price Valid Until: 2026-01-08

Product In-Stock: InStock

5

中文 (中国)

中文 (中国) Tiếng Việt

Tiếng Việt

admin –

👉 Contact Ms. Yuna for detailed technical consultation and to select the most suitable configuration for your production needs.

Ms. Yuna

📞 Hotline: +84 965 535 348

📧 Email: sales03@cousz.com